THIRD RAIL ELECTRICAL

EQUIPMENT OF THE

NEW YORK, NEW HAVEN AND HARTFORD RAILROAD.

(Continued from SCIENTIFIC AMERICAN

of June 12, 1897.)

In our previous notice of the electrical equipment of a portion

of the lines of the New York, New Haven and Hartford Railroad

we stated that the power house at Berlin was a plain rectangular

structure 106 feet in width by 117 feet long, the sides and one

end being of brick, the other end being temporarily boarded up

until the building shall be extended and completed. The building

is divided longitudinally by a brick partition wall; the front

portion, or that facing the tracks, is two stories in height,

the engines and dynamos being installed in the upper story and

the heaters and various accessories in the basement. The rear

half constitutes the boiler room. Interior views of these rooms

will be found on the front page of this issue.

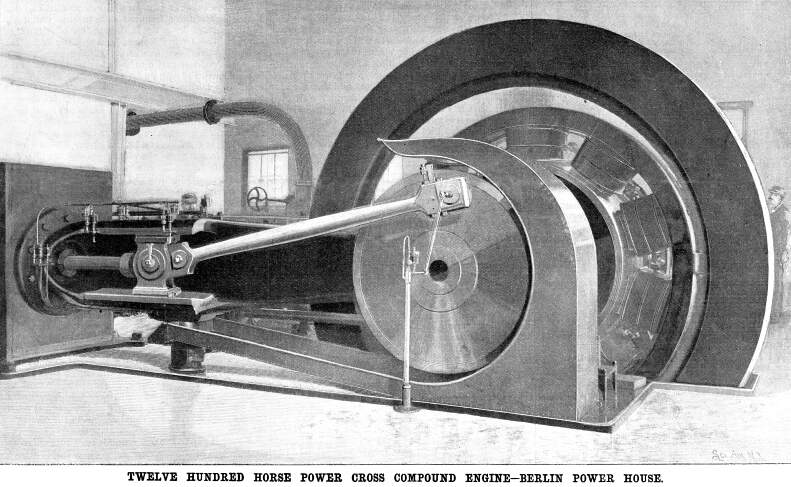

At present the engine room contains a 1,200 horse power engine

of the cross compound type, with a 28 inch by 48 inch high pressure

cylinder and a 48 inch by 48 inch low pressure cylinder. The flywheel

is 18 feet in diameter and weighs over 52 tons. The engine dynamo

shaft is of hollow steel, and the engine is direct connected to

a General Electric Company's standard 10 pole, 850 kilowatt generator

of the ironclad type.

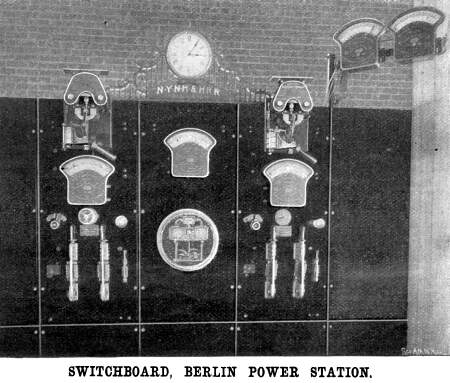

The switchboard shown in the accompanying

illustration is set in a bay built out on the front of the building.

It is of the standard panel type of the General Electric Company

and contains seven panels, of which three only are at present

equipped. Two of these are generating panels and the third is

a totalizing panel. Upon the former are automatic circuit breakers

of extra large size, with magnetic blowout and the usual generator

panel equipment ; the totalizing panel carries a Form G Thompson

5,000 ampere recording wattmeter and an 8,000 ampere station ammeter.

Four cables, each of 850,000 circular mils cross section, run

from the switchboard to the third rail.

The switchboard shown in the accompanying

illustration is set in a bay built out on the front of the building.

It is of the standard panel type of the General Electric Company

and contains seven panels, of which three only are at present

equipped. Two of these are generating panels and the third is

a totalizing panel. Upon the former are automatic circuit breakers

of extra large size, with magnetic blowout and the usual generator

panel equipment ; the totalizing panel carries a Form G Thompson

5,000 ampere recording wattmeter and an 8,000 ampere station ammeter.

Four cables, each of 850,000 circular mils cross section, run

from the switchboard to the third rail.

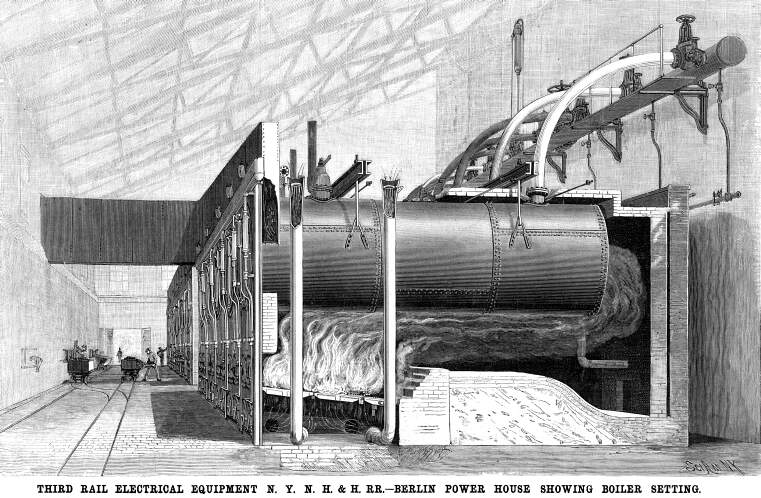

The boiler room contains ten horizontal tubular boilers, which

type has been selected on account of its. "simplicity, high

economy, and general reliability." In setting the boilers,

care has been taken to provide for absolutely free expansion in

all directions, and especially in a direction transverse to the

axis of the boilers. It will be seen from the illustration that

the boilers are suspended from two pairs of I-beams, which

rest upon the brick partition walls, the suspension rods being

linked to straps which are riveted to the shell of the boiler.

The great height (48 inches) from the fire bars to the boiler

is a noticeable feature, and it was adopted in order to secure

a more thorough combustion and a slower passage of the gases to

the uptake. It is claimed that with judicious firing the uptake

temperature has been kept considerably below the normal for this

type of boiler. The grates are designed for burning the half burned

coal known as "sparks," which is recovered from the

fire boxes of the locomotives of the New Haven road. As there

are several hundred tons of this material produced every month,

it can be understood that it is an extremely cheap fuel as delivered

in the bins at the power house. The pipes which lead down through

the partition walls and below the grate are for introducing a

mixture of steam and air to supply the necessary oxygen for combustion.

Each pipe is slightly flaring at the top, and contains an annular

steam pipe perforated on its under side. The gases pass from the

boiler tubes to a rectangular flue, which extends the full length

of the nest of boilers, and delivers into a cross flue 5½

feet wide by 8 feet deep, which leads to a chimney 125 feet, in

height on the outside of the building. The "sparks"

is delivered into a row of bins located on the outside of the

boiler house, and from these it is drawn off as required into

small trucks, which run on a track parallel with the wall of the

building. From this track it is switched on to another track,

which runs at a convenient distance from the furnaces. The fuel

is shoveled directly from the trucks into the furnace. Swinging

trucks are also provided for carrying away the ashes. Special

care has been taken in designing the boiler fronts, which are

held in place by clamps, and may be taken down separately in a

few minutes by loosening the clamps—an arrangement which

will commend itself to practical men at first sight.

Another point which has received special attention is the arrangement

of the steam piping. Col. Heft does not believe that it is good

policy to put in a costly duplicate system of piping, and he is

of the opinion that satisfactory results may be obtained by exercising

care and good judgment in the design and erection of a single

system. Accordingly, every provision has been made for free movement

of the piping under expansion and contraction. In the first place,

a 20 inch wrought iron header runs the entire length of the boiler

room, at a height of eight feet above the boilers. It has a free

longitudinal movement upon rollers, which are carried upon brackets

attached to the central partition wall of the building. Each boiler

is connected with the header by a heavy seamless copper 9 inch

pipe bent to a radius of 8½ feet. The throttle valves are

placed at the junction of these pipes with the header, the valves

being all of the balanced type. Steam is led to the engine by

12 inch wrought iron pipes with bends of large radius. The piping

of the accessory steam plant is so arranged that the engines may

be run as condensing or non-condensing. Each side of the engine

can be run independently and the feed may or may not be heated,

at the option of the engineer.

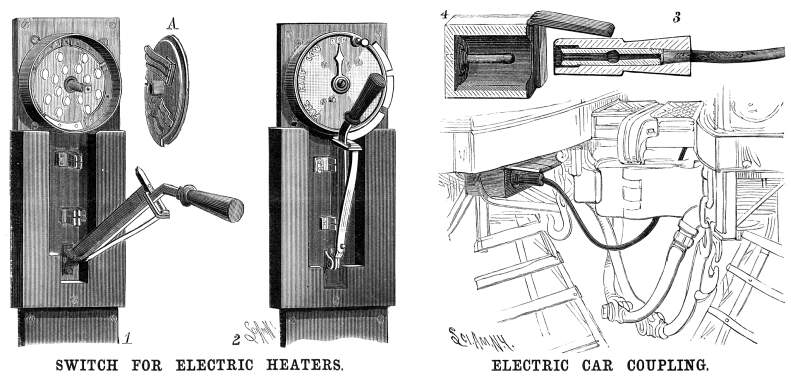

In the illustration showing the various car couplings will

be noticed the electrical car coupling or connector-box. In the

earlier experiments considerable trouble was experienced at the

exposed point where the wires entered the motors, and the connector

box was designed to overcome the difficulty. The connection consists

of a hollow brass tube, split at the outer end to give it a tight

grip of the motor wire, and incased in a wooden plug. There are

two of these and they enter a connector box located beneath the

front end of the platform, as shown in the engraving, the box

being closed by a lid when it is not in use.

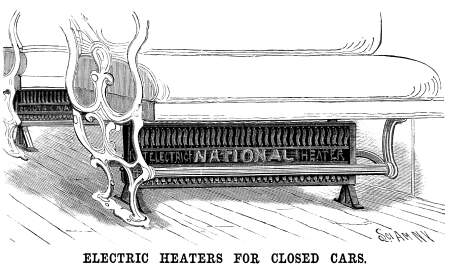

The closed cars are each provided with sixteen electrical heaters,

which are placed beneath the seats as shown in the sketch. The

degree of current and therefore the temperature is regulated by

means of an electrical switch of special construction. There are

four graduations on the dial: full, half, low, and off. The dial,

which is movable, has the brushes attached to its inner face,

and these move upon a series of contacts on the fixed plate. In

order to reduce the spark on opening or closing the switch, the

switch lever is formed separately from the knife, the former being

hinged to the latter near its junction with the switchboard. Normally

the knife is held against the lever by the tension of a plate

spring; but when the lever is pulled open the two are separated,

the knife snapping suddenly against the lever as it leaves the

contacts and reducing the duration of the spark.

The heaters in each coach are connected

in series with each other and form a complete circuit extending

down on one side of the car and up on the other, in which all

of the sixteen heaters are included. This circuit, known as the

series wire, has no connection with the heat-regulating switch,

neither is the positive (trolley) nor the negative (ground) side

of the current supply permanently connected to any portion of

this circuit. A variable ground and trolley connection is carried

by the regulating switch and can be applied by means of tap wires

to one or more points of the series wire or circuit, according

to the amount of heat required. As the heat generated is directly

proportionate to the amount of current flowing through the wires

of each heater, and as this flow of current is governed by the

combined resistance of the heaters through which the current must

flow, it is but necessary to vary the number of heaters between

a point where the current enters and where it leaves again in

order to regulate the temperature to any desired degree.

The heaters in each coach are connected

in series with each other and form a complete circuit extending

down on one side of the car and up on the other, in which all

of the sixteen heaters are included. This circuit, known as the

series wire, has no connection with the heat-regulating switch,

neither is the positive (trolley) nor the negative (ground) side

of the current supply permanently connected to any portion of

this circuit. A variable ground and trolley connection is carried

by the regulating switch and can be applied by means of tap wires

to one or more points of the series wire or circuit, according

to the amount of heat required. As the heat generated is directly

proportionate to the amount of current flowing through the wires

of each heater, and as this flow of current is governed by the

combined resistance of the heaters through which the current must

flow, it is but necessary to vary the number of heaters between

a point where the current enters and where it leaves again in

order to regulate the temperature to any desired degree.

Electric Article 1 |Lines

West | Stories Page | Contents

Page