The Evolution of the American

Locomotive

Scientific American Supplement—May

1, 1897 (Part 2 of 3)

By Herbet T. Walker

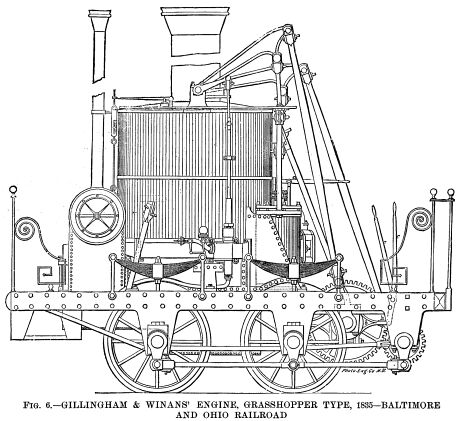

IN the year 1831 a curious design of locomotive

was introduced by Messrs. Davis & Gartner, of York, Pa. It

was run on the Baltimore and Ohio Railroad. The boiler and cylinders

were upright, with four coupled wheels, 30 in. in diameter, but

it was altered considerably after being placed on the road. The

Atlantic was afterward built by the same firm, and was a much

improved engine. Its boiler and cylinders were also vertical,

beams being used to transmit power to the cranks, which were on

a shaft connected by toothed wheels to an intermediate shaft having

outside cranks coupled to the driving wheels. In consequence of

the peculiar shape and movement of the beams, the engines were

called "Grasshoppers." Fig. 6 shows one of this

class manufactured by Gillingham & Winans for the Baltimore

and Ohio Railroad in the year 1835. Wheels 36 in. in diameter;

boiler 52 in. in diameter, containing 400 tubes 1 in. in diameter

and 3 ft. 2 in. long. Diameter of cylinders 10 in. by 24 in. stroke.

Weight of engine and tender; 7 tons 5 cwt. empty. The circular

structure at the base of the small chimney is a fan which was

driven by the exhaust steam before it escaped. IN the year 1831 a curious design of locomotive

was introduced by Messrs. Davis & Gartner, of York, Pa. It

was run on the Baltimore and Ohio Railroad. The boiler and cylinders

were upright, with four coupled wheels, 30 in. in diameter, but

it was altered considerably after being placed on the road. The

Atlantic was afterward built by the same firm, and was a much

improved engine. Its boiler and cylinders were also vertical,

beams being used to transmit power to the cranks, which were on

a shaft connected by toothed wheels to an intermediate shaft having

outside cranks coupled to the driving wheels. In consequence of

the peculiar shape and movement of the beams, the engines were

called "Grasshoppers." Fig. 6 shows one of this

class manufactured by Gillingham & Winans for the Baltimore

and Ohio Railroad in the year 1835. Wheels 36 in. in diameter;

boiler 52 in. in diameter, containing 400 tubes 1 in. in diameter

and 3 ft. 2 in. long. Diameter of cylinders 10 in. by 24 in. stroke.

Weight of engine and tender; 7 tons 5 cwt. empty. The circular

structure at the base of the small chimney is a fan which was

driven by the exhaust steam before it escaped.

This fan was for urging the fire. It was, however, subsequently

removed and the exhaust steam turned into the large chimney in

the usual way. This engine and seven other similar ones were in

constant service on the Baltimore and Ohio Railroad for a period

of over fifty years. Some of them are now in the Field Museum.

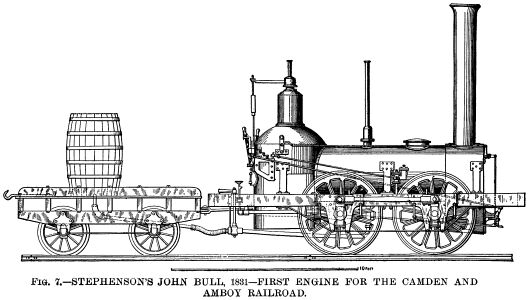

Fig. 7 shows the celebrated John Bull, which is now

in the National Museum, Washington, D. C. It was the first engine

for the Camden and Amboy Railroad, now a part of the Pennsylvania

Railroad. It was designed and built by Stephenson & Company,

of Newcastle upon Tyne. This engine represents another step in

locomotive construction, for while it somewhat resembles the De

Witt Clinton, the cylinders are placed at the smoke box end of

the engine, and the smoke box is of the same pattern as used to-day;

both these improvements were embodied in the before mentioned

Planet engine designed by Stephenson early in the year 1830.

This engine (John Bull) was ordered by Robert L. Stevens, President

of the Camden and Amboy Railroad, from Messrs. Stephenson &

Company, in December, 1830, and was shipped to Bordentown, N.

J., where it arrived in August, 1831. The cut (Fig. 7)

was made from a drawing now in the Washington Museum, and is said

to be an exact representation of the engine when it arrived in

this country; but in a copy of one of Stephenson's working drawings

in the author's possession the engine is shown with a chimney

of different shape and with a different arrangement of safety

valves. This matter is small in itself, but illustrates one of

the many difficulties that confront a writer who undertakes to

show and describe locomotives built so many years ago.

The engine was originally named Stevens, but

on its arrival in this country the railroad company called it

John Bull, and it was entered in their books as "No. 1."

It was put in service November 12, 1831, at Bordentown, N.J.,

where the Railroad Monument now stands. The leading dimensions

were as follows: The engine was originally named Stevens, but

on its arrival in this country the railroad company called it

John Bull, and it was entered in their books as "No. 1."

It was put in service November 12, 1831, at Bordentown, N.J.,

where the Railroad Monument now stands. The leading dimensions

were as follows:

Weight about 10 tons, boiler, 3 ft. 6 in. diameter; cylinders,

9 in., diameter by 20 in. stroke. Four coupled wheels 4 ft. 6

in. diameter, with cast iron hubs and locust wood spokes and felloes.

Tires of wrought iron ¾ in. thick; sixty-two tubes, 7 ft.

6 in. long by 2 in. diameter. Furnace 3 ft. 7 in. long by 3 ft.

2 in. high (for burning wood). Heating surface of tubes, 213 sq.

ft.; of firebox, 36 sq. ft. Total heating surface, 249 sq. ft.

The firebox was of the dome or Bury pattern. The reversing gear

was complicated, the two eccentrics being secured to a sleeve

or barrel, which fitted loosely on the crank shaft. A treadle

was used to change the position of this loose eccentric sleeve,

moving it to the right or left lengthwise on the shaft. Two carriers

were secured firmly to the shaft (one on each side of the eccentrics);

one carrier worked the engine ahead, the other back, so that when

the eccentrics were half way between the two carriers, the axle

turned without moving them, and the engine was out of gear. In

order to reverse, the engine driver placed his foot on the treadle

(which is between the firebox and the handle of the feed water

cock), thereby disengaging the eccentrics from the carriers he

then pulled a small handle on the right side of the boiler and

so lifted the small ends of the eccentric rods (which passed forward

to the rocking shaft on the front of the engine) clear of the

valve stems, after which he took hold of the two valve levers

on the foot plate, and by moving them back and forth admitted

steam to the cylinders by the hand gear; when the engine was fairly

started, he, by means of the treadle, caused the eccentrics to

engage with the opposite carrier, and it continued to actuate

the valves.

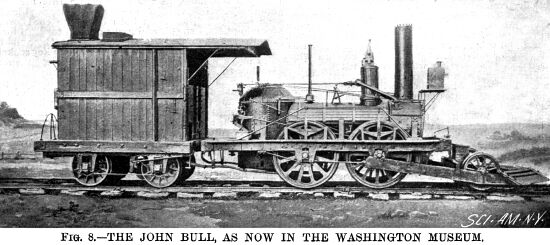

Soon after the engine arrived, the Camden

and Amboy mechanics made the following changes and additions:

As the railroad curves were very sharp, the coupling rods and

cranks were removed and a lateral play of 1½ in. given

to the leading axle, to which a cowcatcher was connected. The

wooden wheels were replaced by cast iron wheels. The dome was

moved forward to the former man hole and the boiler lagged with

wood. A bell was placed on the boiler and a headlight on the smoke

box. A new tender was subsequently built, having a small cab on

the rear for the accommodation of a brakeman, who, if anything

went wrong with the cars, could signal the engine driver to stop.

The engine then presented the appearance shown in Fig. 8.

From a cut in the Railroad Gazette of March 9, 1877. it appears

that a cab and a large wood-burning chimney were subsequently

added, but both these were removed some time before the engine

was placed in the United States National Museum. Soon after the engine arrived, the Camden

and Amboy mechanics made the following changes and additions:

As the railroad curves were very sharp, the coupling rods and

cranks were removed and a lateral play of 1½ in. given

to the leading axle, to which a cowcatcher was connected. The

wooden wheels were replaced by cast iron wheels. The dome was

moved forward to the former man hole and the boiler lagged with

wood. A bell was placed on the boiler and a headlight on the smoke

box. A new tender was subsequently built, having a small cab on

the rear for the accommodation of a brakeman, who, if anything

went wrong with the cars, could signal the engine driver to stop.

The engine then presented the appearance shown in Fig. 8.

From a cut in the Railroad Gazette of March 9, 1877. it appears

that a cab and a large wood-burning chimney were subsequently

added, but both these were removed some time before the engine

was placed in the United States National Museum.

As far as the writer can discover, this was the first engine

equipped with a bell, headlight and cowcatcher, although bells

were used on English locomotives as far back as 1827.

This remarkable locomotive was exhibited at the Philadelphia

Exposition of 1876, and again at the Chicago Exposition of Railway

Appliances in 1883, and lastly, at the Columbian Exposition of

1893. Leaving New York City under steam April 17, 1893, it hauled

"the John Bull train" of two cars 912 miles, without

assistance, to Chicago, arriving April 22, and meeting with continued

ovation over the entire route. It formed part of the Pennsylvania

Railroad Company's exhibit, and was one of the great attractions

of the World's Fair, carrying over fifty thousand passengers over

the exhibition tracks in the terminal station yard. The engine

left Chicago again under steam December 5, 1893, coming east over

the Pennsylvania lines via the Southwest system to Pittsburgh,

and through Altoona, Harrisburg and Baltimore to Washington, arriving

there December 13, 1893. This was a very good performance for

a locomotive sixty-two years of age. It was then returned to the

museum at Washington, where it will remain permanently.

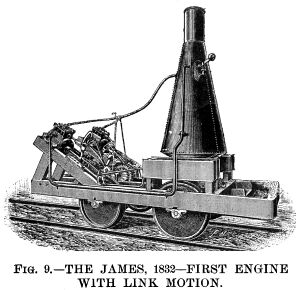

In the year 1832, William T. James, of New York, invented a

very important improvement in locomotive valve gear, viz., the

link motion. This reversing and expansion gear is the embodiment

of "the beauty of simplicity," for, while the valve

gears up to that time and for years afterward were largely made

up of a complication of rods and levers, as in the John Bull,

they only served to reverse the engine and did not admit of the

steam being worked with a varying degree of cut-off and expansion,

so essential to the economical working of a locomotive. James'

design was nothing more nor less than connecting the small ends

of the fore and back gear eccentric rods by a curved link, the

curve being concave toward the eccentrics, said link having a

slot which engaged a slide block, fastened to the valve stem.

By a hand lever the engine driver could move the link up or down,

thus causing either the fore or back gear eccentric to communicate

motion to the slide valve and so control the direction of the

engine's motion.

The effect of this device as a cut-off mechanism is that when

the slide block is in the center of the link, midway between the

two eccentric rods, the engine will be in midgear, but on the

link being moved so as to bring one of the eccentric rods—say

the fore gear rod—opposite to the block, and steam being

admitted, the engine will move forward and the valve will cut

off the steam when the piston is nearly at the end of its stroke;

if the link is moved so that the block will occupy a position

between the eccentric rod and the center of the link, the slide

valve will cut the steam off at an earlier period of the piston's

stroke and so leave the rest of the stroke to be performed by

the expansion of the steam, and the more nearly the center of

the link is brought to the slide block the shorter becomes the

travel of the valve and the earlier will the steam be cut off.

Thus, the rate of cut-off and degree of expansion, either for

fore or back gear, can be regulated while the engine is running

and according to the work it has to do.

This is one of the simplest inventions in the world. There

is no valve gear equal to it, and it is used on nearly every locomotive

to-day.

James' engine of 1832 (see Fig. 9),

fitted with the link motion, was intended for the Baltimore and

Ohio Railroad. The boiler was vertical and of weak construction.

The cylinders were 8 in. in diameter by 12 in. stroke and the

slide valves had ½ in. lap at each end. The gross weight

was 3½ tons. There were four wheels (not coupled) 3 ft.

in diameter. James' engine of 1832 (see Fig. 9),

fitted with the link motion, was intended for the Baltimore and

Ohio Railroad. The boiler was vertical and of weak construction.

The cylinders were 8 in. in diameter by 12 in. stroke and the

slide valves had ½ in. lap at each end. The gross weight

was 3½ tons. There were four wheels (not coupled) 3 ft.

in diameter.

A representative of the American Railroad Journal visited Mr.

James' shop at 40 Eldridge Street, New York City, to examine his

wonderful locomotive which had just been completed. He states

that the engine was run on a track fifty feet in length, backward

and forward eight times in 63 seconds, including stops: Although

he does not describe the valve motion, it is evident that none

but the most efficient reversing gear, such as the link motion

is, would have secured such a result. He also states that Mr.

James (a few days later) placed the engine on wheels without flanges

and ran it over the pavements and Third Avenue to Yorkville, about

five miles, where he took breakfast and then returned to the city.

[American Railroad Journal, October 29, 1832.]

It may be mentioned that a weight, which can be seen in Fig.

9, was fixed on the reversing lever to retain the links in

position for fore or back gear, there being no means of fixing

them in an intermediate position; but Mr. Samuel B. Dougherty

(subsequently locomotive superintendent of the Camden and Amboy

Railroad), who assisted in the construction of this engine, and

wrote a description of it in May; 1858, said that "in setting

the eccentrics we found the link would cut off, and we so used

it on the engine to expand from different points." [Colburn's

Locomotive Engineering and Mechanism of Railways, 1871.]

Before this engine was sent to Baltimore it was run for some

time on the Harlem Railroad, where it worked satisfactorily. In

1833 it was forwarded to its destination, but, soon after having

been placed in regular service, the boiler exploded and the engine

was totally destroyed. A full size model of this engine was sent

to the Columbian Exposition.

Strange to say, the link motion after this appears to have

dropped out of sight, American engineers using a variety of fork

or hook motions, all more or less objectionable, until ten years

later, when we will again take the matter up in its chronological

order.

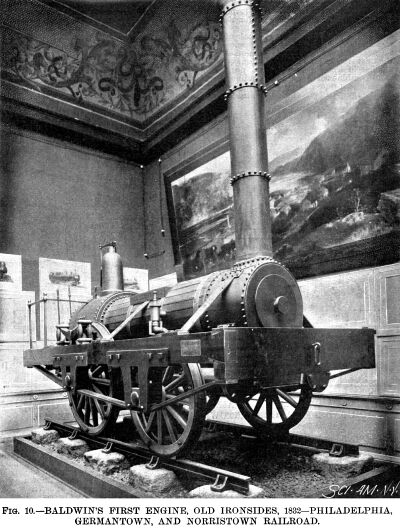

In the year 1832, Matthew W. Baldwin, founder

of the famous Baldwin Locomotive Works, received an order for

a locomotive from the Philadelphia, Germantown and Norristown

Railroad Company, whose short line of six miles was operated by

horse power. He, in company with his friend, Mr. Peale, went to

Bordentown to examine one of Stephenson's engines (probably the

John Bull) on the Camden and Amboy Railroad, and made some memoranda

of its principal dimensions. After many difficulties had been

surmounted, he built a locomotive and christened it Old Ironsides.

It was tried on the road November 23, 1832, and is shown in Fig.

10. In the year 1832, Matthew W. Baldwin, founder

of the famous Baldwin Locomotive Works, received an order for

a locomotive from the Philadelphia, Germantown and Norristown

Railroad Company, whose short line of six miles was operated by

horse power. He, in company with his friend, Mr. Peale, went to

Bordentown to examine one of Stephenson's engines (probably the

John Bull) on the Camden and Amboy Railroad, and made some memoranda

of its principal dimensions. After many difficulties had been

surmounted, he built a locomotive and christened it Old Ironsides.

It was tried on the road November 23, 1832, and is shown in Fig.

10.

A full size model of this engine is now in the Field Columbian

Museum, Chicago. Its chief dimensions were as follows: Driving

wheels, 4 ft. 6 in. diameter; leading wheels, 3 ft. 9 in. diameter;

cylinders, 9½ in. in diameter by 18 in. stroke. They were

attached horizontally to the outside of the smoke box, just inside

the frames, which were of wood, with iron pedestals. The wheels

were made with heavy cast iron hubs, wooden spokes and rims, and

wrought iron tires. The boiler was 30 in. in diameter, and contained

72 copper tubes 1½ in. diameter and 7 ft. long. The reversing

gear consisted of a single eccentric, with a double latch eccentric

rod gearing alternately on pins on the upper and lower ends of

the arms of a rocking shaft. It will be seen that the Ironsides

closely

resembled the John Bull, except that the leading wheels were

smaller than the driving wheels, and the firebox was of the regular

Stephenson type instead of the dome or Bury pattern.

This engine weighed about 8 tons and was able to draw 30 tons

on a level. It was the first locomotive Mr. Baldwin ever built,

and did duty on the Germantown and other roads for over a score

of years, and was seen by Zerah Colburn at the Fitchburg Railroad

station, Boston, in 1853. It is but justice to Baldwin to add

that he soon abandoned the English design of the Ironsides and

quickly placed himself at the front in American locomotive practice,

some of the finest engines in their day having been built by him.

American designs very soon began to depart from their British

prototypes, and a process of adaptation to the existing conditions

of the railroads in this country followed.

Until recently, a marked feature of difference between American

and English locomotives has been the use of the swiveling truck

under the former to facilitate the passage of the engine around

curves. An English patent dated December 30, 1812, was granted

to William and Edward Chapman for a four wheeled swiveling truck.

In the year 1815, Messrs. Blackett & Hedley constructed a

locomotive named Puffing Billy for the Wylam Colliery Railway,

having two four wheeled trucks, but the truck did not come into

general use in England until about thirty years ago.

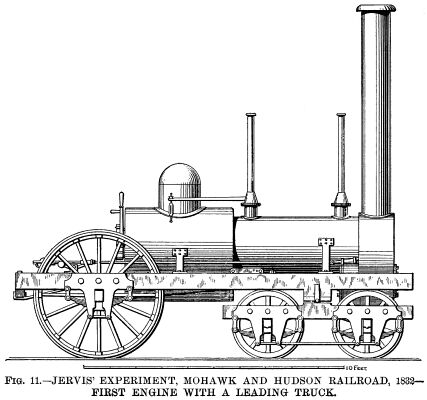

In the year 1831 Mr. Horatio Allen designed

an engine with two trucks for the South Carolina Railroad, of

which he was then the chief engineer, but to Mr. John B. Jervis,

chief engineer of the Mohawk and Hudson Railroad, belongs the

honor of designing the first engine with a leading truck swiveling

on a center pin, as generally used the world over to-day. This

was in the year 1831; and in the year 1832 his engine Experiment

was put on the above named road for regular service. The cylinders

were 9-and-five-eighths in. in diameter by 16 in. stroke. Diameter

of driving wheels, 5 ft. Grate 5 ft. long, for burning anthracite

coal. Weight 7½ tons. This important locomotive is shown

in Fig. 11. It was the ordinary uncoupled or single driving

wheel engine as commonly used at that period, and, as it presents

no novel features aside from the truck, further description is

unnecessary. [An interesting letter from Mr. Jervis, with an illustration

of his Experiment, appeared in the Railroad Gazette, Vols. III

and IV.] In the year 1831 Mr. Horatio Allen designed

an engine with two trucks for the South Carolina Railroad, of

which he was then the chief engineer, but to Mr. John B. Jervis,

chief engineer of the Mohawk and Hudson Railroad, belongs the

honor of designing the first engine with a leading truck swiveling

on a center pin, as generally used the world over to-day. This

was in the year 1831; and in the year 1832 his engine Experiment

was put on the above named road for regular service. The cylinders

were 9-and-five-eighths in. in diameter by 16 in. stroke. Diameter

of driving wheels, 5 ft. Grate 5 ft. long, for burning anthracite

coal. Weight 7½ tons. This important locomotive is shown

in Fig. 11. It was the ordinary uncoupled or single driving

wheel engine as commonly used at that period, and, as it presents

no novel features aside from the truck, further description is

unnecessary. [An interesting letter from Mr. Jervis, with an illustration

of his Experiment, appeared in the Railroad Gazette, Vols. III

and IV.]

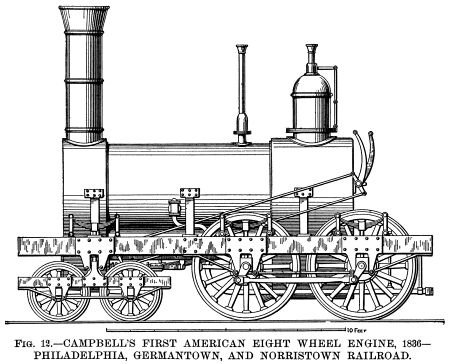

As time went on, it was found that one pair of driving wheels

did not furnish sufficient adhesion and power for the ever increasing

loads to be hauled, and, therefore, the next step was to utilize

the four coupled wheels embodied in some of the engines previously

illustrated and combine them with the leading truck. This arrangement

was patented in 1836 by Henry R. Campbell, chief engineer of the

Germantown Railroad, "in order to distribute the weight of

the engine upon the rails more completely." In the same year

he designed the freight engine shown in Fig. 12 (the previous

engines were used for both freight and passenger trains), and

thus we have the first American eight wheeled engine. It had cylinders

14 in. diameter by 16 in. stroke. Driving wheels 4 ft. 6 in. diameter,

the forward pair being without flanges. Gross weight about 12

tons, the adhesive weight being 8 tons. Heating surface about

725 sq. ft. It was tried on the Philadelphia and Germantown Railroad,

May 8, 1837, but was found to be a "hard rider," for

the reason that it had no means of equalizing the weight on the

driving wheels so as to meet the various undulations in the track,

and it would also appear from the drawing that the truck had no

center pivot, the frame being made with  vertical

projections sliding in pedestals on the main frame, and being

connected thereto by side springs. If this was the case, the truck

could only vibrate in a vertical plane and could not turn horizontally.

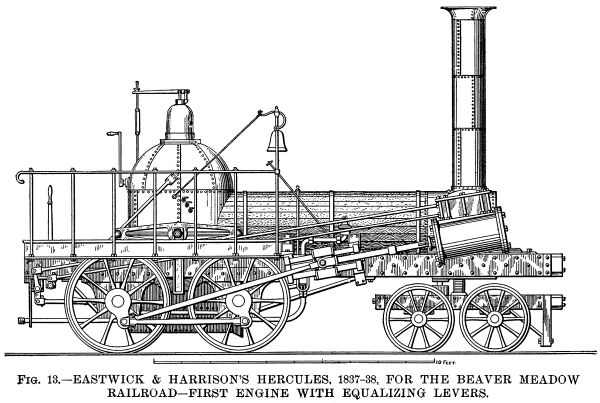

To remedy the defects of the Campbell engine, Messrs. Garret &

Eastwick, of Philadelphia, completed in 1837 a new style of freight

locomotive for the Beaver Meadow (now the Lehigh Valley) Railroad

Company. This engine, named Hercules, had a separate rectangular

frame for the four coupled wheels, this frame being pivoted on

each side to the main frame by springs and journal boxes sliding

vertically in pedestals on the main frame. Thus the separate frame

was enabled to move up and down as well as to swing vertically

on its center, and so permit the four driving wheels to accommodate

themselves to the unevenness of the track, provided the undulations

were alike on both rails, which of course, never happened, and

the "separate frame" got badly racked in consequence. vertical

projections sliding in pedestals on the main frame, and being

connected thereto by side springs. If this was the case, the truck

could only vibrate in a vertical plane and could not turn horizontally.

To remedy the defects of the Campbell engine, Messrs. Garret &

Eastwick, of Philadelphia, completed in 1837 a new style of freight

locomotive for the Beaver Meadow (now the Lehigh Valley) Railroad

Company. This engine, named Hercules, had a separate rectangular

frame for the four coupled wheels, this frame being pivoted on

each side to the main frame by springs and journal boxes sliding

vertically in pedestals on the main frame. Thus the separate frame

was enabled to move up and down as well as to swing vertically

on its center, and so permit the four driving wheels to accommodate

themselves to the unevenness of the track, provided the undulations

were alike on both rails, which of course, never happened, and

the "separate frame" got badly racked in consequence.

To overcome this objection, Mr. Joseph Harrison, Jr., of the

firm of Eastwick & Harrison, patented in 1838 an improvement

for equalizing the weight on the wheels of locomotive engines.

The preferred form consisted in placing the driving axle bearings

in pedestals on the main frame in the usual manner (the separate

frame being discarded), and, instead of connecting the driving

wheel axle boxes directly to the frame by springs (as in Campbell's

engine), a horizontal beam or lever was introduced, having a central

pivot linked to a spring fastened to the frame, and its ends provided

with rods that passed down through the frame and abutted on said

axle boxes. There were two of these levers, one on each side of

the engine. They vibrated separately and thus met all the unevenness

in both rails. In all equalized engines now built in this country

or in Europe this device of Mr. Harrison's is used in one or other

of the different ways indicated in his patent. [The Locomotive

Engine, by Joseph Harrison, Jr.]

These compensating levers are known as equalizers, because'

when running on an uneven track, they distribute the shock or

jar equally over all the wheels so connected.

Fig. 13 is a side elevation of this important engine

as rearranged with Harrison's equalizing levers, and a full size

model of it is now in the Field Museum, Chicago. The engine had

12 in. cylinders by 18 in. stroke, and four coupled driving wheels

3 ft. 8 in. diameter. Its gross weight was about 14 tons, of which

9 tons were available for adhesion. With steam of 90 lb. pressure

per square inch (then a common pressure in this country) the engine

drew a load of 265 tons, including the tender, up a grade varying

from 27 ft. to 35 ft. per mile. The speed was not given, but the

other particulars are derived from the report of a committee of

the Franklin Institute, dated May 9, 1839.

While there is no doubt that Harrison was

the original inventor of equalizing levers as used at the present

day, it is necessary to call attention to the fact that Timothy

Hackworth (Stephenson's great rival) rebuilt a six coupled engine,

named Royal George, for the Stockton and Darlington Railway, in

the year 1827; each of the middle and back wheels were equalized

by a spring in the same way as shown in Fig. 2 of Harrison's specification

above referred to. A drawing of the Royal George will be found

in Colburn's Locomotive Engineering and Mechanism of Railways,

page 21. While there is no doubt that Harrison was

the original inventor of equalizing levers as used at the present

day, it is necessary to call attention to the fact that Timothy

Hackworth (Stephenson's great rival) rebuilt a six coupled engine,

named Royal George, for the Stockton and Darlington Railway, in

the year 1827; each of the middle and back wheels were equalized

by a spring in the same way as shown in Fig. 2 of Harrison's specification

above referred to. A drawing of the Royal George will be found

in Colburn's Locomotive Engineering and Mechanism of Railways,

page 21.

Before dismissing the Hercules, we will notice the reversing

gear, which was patented by Mr. A. M. Eastwick, July 21, 1835,

and is very simple and ingenious. It will be seen by Fig. 13

that the valve chest had two valve stems projecting therefrom.

The upper one was for the ordinary slide valve and was connected

to a rocking shaft actuated by a single eccentric on the rear

axle. The lower one was connected to a movable block working between

the slide valve and the cylinder ports. This movable block had

four ports, two for fore gear and two for back gear. The fore

gear ports (called direct ports) opened directly into the cylinder

in the usual way, but the back gear ports (called indirect ports)

went but half way through the block, and then turned and passed

each other before entering the cylinder. When it was desired to

run the engine backward, the block was moved by the hand lever

on the foot plate to bring the indirect ports in communication

with the cylinder, so that when the slide valve admitted steam

to the front port in the block it was conducted to the back end

of the cylinder and vice versa. A similar device was patented

in England by William Beckett Johnson in the year 1847.

It is interesting to note that Mr. Harrison, in conjunction

with Mr. Winans, afterward constructed and worked the rolling

stock of the St. Petersburg and Moscow Railway in Russia, and

all the engines, nearly 200 in number, originally made at Alexandrowski,

near St. Petersburg, were fitted with Eastwick's reversing valve

block, and, with the addition of a separate expansion valve, these

engines were running as late as the year 1871.

(To be continued.)

Antebellum RR

| Contents Page

|