IMPROVEMENTS IN THE CABLE RAILWAY IMPROVEMENTS IN THE CABLE RAILWAY

OF THE NEW YORK AND BROOKLYN BRIDGE.

Scientific American—

July 21, 1888

Our readers who have not seen the great East River Bridge which

connects New York and Brooklyn have been made familiar with its

appearance and the details of its construction through the frequent

and profusely illustrated articles on the subject which have appeared

in these columns from time to time. It is not necessary, therefore,

to go into minutiæ regarding the structure itself, but it

will, perhaps, be well to repeat in brief some of the dimensions

of the bridge, and give some facts regarding the traffic.

The bridge is 5,989 feet long, 85 feet wide, supported by four

15¾ inch wire cables. It is divided into five longitudinal

divisions: the carriage ways being at the outside, the elevated

promenade in the middle, and the two railways between the promenade

and the carriage ways. An endless cable, 1½ inches in diameter,

extends from the engine house in Brooklyn over sheaves at the

center of the railway track to the New York terminus, thence across

underneath the New York approach to the other railway, returning

in the same manner.

The propelling plant, which has been in use upon the bridge

from the day of its opening up to the present time, consisted

of two horizontal steam engines, each having a cylinder 26 inches

in diameter, a stroke of 48 inches, with a fly wheel 18 feet in

diameter, weighing 30,000 pounds. These engines have been operated

one at a time, jaw clutches being provided for throwing one or

the other of the engines into gear with the cable drums, as required.

The entire traffic of the railway has been carried on by means

of 3-car trains, propelled by these engines through the medium

of the cable.

Since the completion of the bridge, the growth of the traffic

has been so regular and so rapid as to render apparent the necessity

of increasing the carrying facilities. In April, 1884, 752,220

passengers were carried over the bridge. In April, 1888, 2,593,104

passengers were carried. If the traffic were evenly distributed

through the day, the 3-car trains could readily carry the passengers

for some time to come; but, as is well known, the traffic varies

greatly with different hours of the day. For example: in the hour

beginning at 8 o'clock in the morning, from 10,000 to 12,000 people

are carried from Brooklyn to New York, while less than 1,000 are

carried from New York to Brooklyn. In the hour beginning at 5

o'clock in the afternoon, from 9,000 to 10,000 people are carried

from New York to Brooklyn, while only about 1,500 are carried

at the same hour from Brooklyn to New York. In the middle of the

day the average in either direction is about 2,000 per hour, and

at midnight scarcely more than one-tenth of that number.

This enormous traffic exceeds the original expectations, and the

great and abrupt fluctuations of power required to propel the

trains at these busy hours have severely tested the engines. One

day's record showed that the power ranged from 303 h.p., as a

maximum to 129 h.p. negative, as a minimum. We are informed of

one instance in which there was an increase of 190 h.p. within

15 minutes, and another in which the power was increased by 239

h.p. within 80 minutes.

To provide economically for the present traffic, to anticipate

future increase, as well as to provide for various improvements

which have been developed by conditions peculiar to this particular

railway, and to guard against any suspension of traffic by any

possible accident to a part of the machinery, a new driving plant

has been constructed and put in operation.

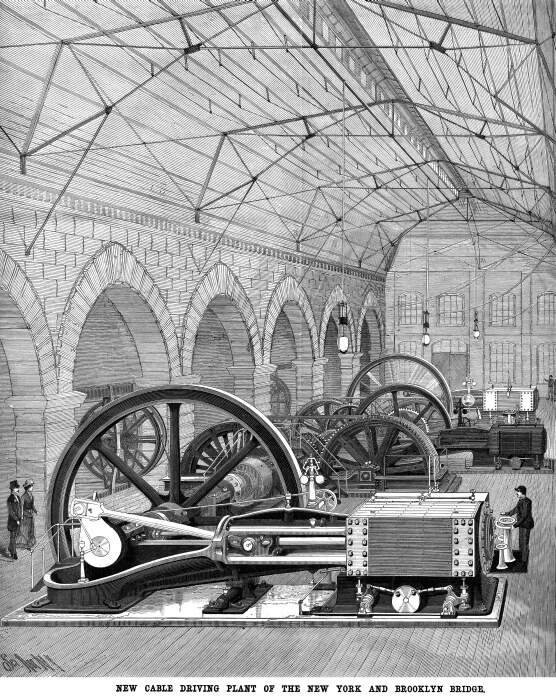

The old machinery is located in one of the arches of the approach

adjoining the Brooklyn station. The engines of the new plant are

contained by a substantial brick building adjoining the north

side of the approach, and abutting against the boiler house. In

this building are placed three magnificent engines, built by William

Wright, of Newburg, New York. They are of the girder type, of

graceful design and elegant finish. These engines are placed parallel

with each other, and arranged to be coupled independently with

the cable drums. They are of three sizes; the largest one (625

h.p.), for propelling the trains at night and morning, has a cylinder

30 inches in diameter, with a stroke of 48 inches; the next in

size (400 h.p.) has a cylinder of 26 inches in diameter, with

a stroke of 48 inches; the smallest one (275 h.p.) has a cylinder

of 22 inches in diameter, with a stroke of 36 inches. The fly

wheel of the largest engine is 20 ft. in diameter, and weighs

50,000 lb.; the fly wheel of the next is 20 ft. in diameter, and

weighs 40,000 lb.; and the fly wheel of the smallest engine is

15 ft. in diameter, and weighs 16,000 lb. The smallest engine

is connected with the driving shaft by means of gearing and clutches;

the larger engines are connected direct by means of clutches.

The driving shaft is made in sections, and arranged to be connected

by jaw clutches and friction clutches, so that either of the engines

may be brought into connection with either pair of cable drums.

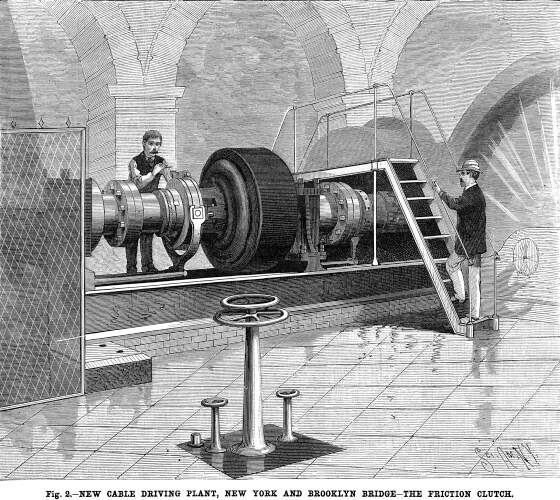

Each engine is provided with a friction clutch by which it may

be thrown into engagement with the driving shaft while the cable

and driving machinery is in motion, so that the engines may be

shifted without loss of time.

One of these ponderous clutches

is shown in Fig. 2. In the foreground of the picture may be seen

the usual column and throttle valve wheel for starting and stopping

the engine; also another wheel arranged upon a hollow shaft inclosing

the throttle valve spindle, and connected with the clutch-operating

mechanism. The operation of shifting the engines consists in starting

the engine by means of the throttle valve in the usual way, and

when the engine attains its normal speed, throwing in the clutch

by means of the clutch-operating wheel, then disconnecting the

clutch of the engine to be taken off. One of these ponderous clutches

is shown in Fig. 2. In the foreground of the picture may be seen

the usual column and throttle valve wheel for starting and stopping

the engine; also another wheel arranged upon a hollow shaft inclosing

the throttle valve spindle, and connected with the clutch-operating

mechanism. The operation of shifting the engines consists in starting

the engine by means of the throttle valve in the usual way, and

when the engine attains its normal speed, throwing in the clutch

by means of the clutch-operating wheel, then disconnecting the

clutch of the engine to be taken off.

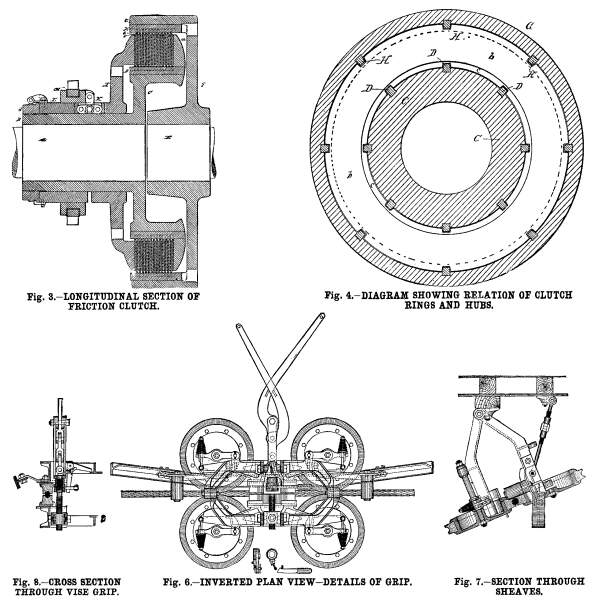

The details of the friction clutch are shown in Figs. 3 and

4, Fig. 3 being a longitudinal section of a clutch and Fig. 4

a diagram showing the relation of the clutch rings. To the engine

shaft, A, is attached a sleeve, B, provided with a hub, C, which

supports the friction rings, b c, the hub being provided

with a flange, a, forming an abutment for the friction

rings. In the hub, C, are inserted eight feathers, D. The rings,

b c, are of two diameters, the rings, b, of smaller

diameter being slotted to receive the feathers, D. The rings,

c, which are of larger diameter, are slotted in their peripheries

to receive eight feathers, H, inserted in the rim, G, of, the

hub, F, secured on the shaft, E. By this arrangement, it will

be noticed that all of the rings, b, must turn with the

hub, F, and all of the rings, c, must turn with the hub,

C.

Upon the sleeve, B, is placed a clamping collar, I, which is

capable of being forced into contact with the series of rings,

b c, clamping them tightly against the flange, a.

On the sleeve, B, is placed a

sleeve, L, which abuts against an adjusting ring, d, screwed

on the end of the sleeve, B. The sleeve, L, forms an abutment

for toggles, K, three in number, which serve to force the clamping

collar, I, into contact with the rings, b c. On the sleeve,

L, is placed a grooved ring, M, arranged to work the toggles,

K, and in the groove of the ring, M, is placed a strap, which

is connected through a system of levers with the clamping wheel

before referred to. A is the driven shaft, E the driver. When

the toggles, K, are loosened, the shaft, E, turns independently

of the shaft, A; but when the toggles are straightened, bringing

the friction rings, b c, into forcible contact with each

other, the shaft, E, will carry the shaft, A. On the sleeve, B, is placed a

sleeve, L, which abuts against an adjusting ring, d, screwed

on the end of the sleeve, B. The sleeve, L, forms an abutment

for toggles, K, three in number, which serve to force the clamping

collar, I, into contact with the rings, b c. On the sleeve,

L, is placed a grooved ring, M, arranged to work the toggles,

K, and in the groove of the ring, M, is placed a strap, which

is connected through a system of levers with the clamping wheel

before referred to. A is the driven shaft, E the driver. When

the toggles, K, are loosened, the shaft, E, turns independently

of the shaft, A; but when the toggles are straightened, bringing

the friction rings, b c, into forcible contact with each

other, the shaft, E, will carry the shaft, A.

The capacity of the clutch is increased by increasing the number

of the rings, b c. The clutch for the large 625 horse power

engine has 27 rings, the clutch for the 400 horse power engine

has 19 rings, and the clutch for the 275 horse power engine has

13 rings.

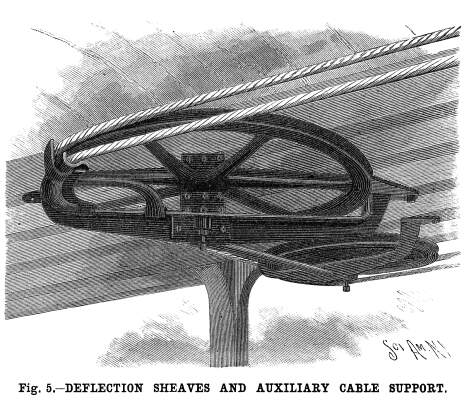

To guard against every possible emergency, all the important

parts of the machinery have been made in duplicate. There are

two sets of driving drums, two cables, one in motion and the other

in reserve. The cable running out from the engine house passes

over the deflection sheaves around sheaves carried by the tension

car, thence outward, and the incoming or hauling end of the cable

passes around a set of deflection sheaves, thence downward underneath

the upper floor of the Brooklyn station to a large sheave revolving

in a horizontal plane, and shown in Fig. 5, thence back to the

propelling drums. The second cable, which is held in reserve,

passes around an extra set of propelling drums and is supported

near the sheaves, in readiness to be transferred to them in case

of necessity. The transfer of cables requires about one hour,

and while it is being done the trains are carried over the bridge

by locomotives.

The grip now used is shown in

Figs. 6 to 8 inclusive; Fig, 6 being an inverted plan view, Fig.

7 a section through the sheaves, and Fig. 8 a central cross section. The grip now used is shown in

Figs. 6 to 8 inclusive; Fig, 6 being an inverted plan view, Fig.

7 a section through the sheaves, and Fig. 8 a central cross section.

In the grip there are four sheaves placed in pairs, so that the

cable is gripped between each pair. Each sheave has a heavy grooved

rim with a cylindrical inner surface against which the brake presses.

The rim is in. two parts bolted together, and holds in a dovetail

groove a packing of leather and India rubber belting in alternating

pieces placed radially. The packing projects well out of the rim,

and is grooved to receive the cable.

There are four brakes, one for each sheave. They are made of

hard wood, with a curved outer face fitted to the inside of the

rim of the sheave.

The main frame of the grip is in two parts, each hinged in

a common line parallel to the cable, close under the car floor,

one part hanging on each side of the cable. The sheaves are each

carried by a small frame hinged to the main frame, on a line parallel

to the shaft of the sheave. This small frame has a limited movement

opposed by a coiled spring which tends to force the sheave away

from its brake. Each of the four brakes is held by a projecting

end of the main frame. The upper part of the main frame, from

which the operating levers project, is fixed in position by adjustable

stay rods. The movable part is connected to the operating levers

by a coarse-threaded screw which is turned by a ratchet wheel

and pawl.

As the grip is used the packing in the grooves of the sheaves

is slowly compressed and worn, thereby permitting the sheaves

to come more nearly together as the grip is closed, and the short

arms of the operating levers approach more closely to a straight

line, and as this continues, the pressure on the packed surfaces

increases rapidly. Such action is prevented, when, as the grip

is closed, a certain position of the levers in approaching each

other is passed, by the pawl engaging with the tooth of the ratchet

wheel, then, as the levers are separated, the screw is turned

slightly, bringing the sheave surfaces and levers to their former

and normal relative positions. As the grip is closed and the sheaves

are brought into contact with the cable, they are revolved at

cable speed, the car being at rest. As power is applied to the

brakes, the sheaves are forced together with an increasing pressure,

which is transmitted from the brakes to the sheaves, developing

a frictional resistance which tends to prevent the sheaves from

revolving. This action continues until the resistance in the four

sheaves exceeds the tractive resistance of the car, when the sheaves

cease to revolve and the car moves at cable speed.

The vise grip (which grasps the cable only as the frames and

sheave packing yield) is intended to take full hold after the

sheaves cease to revolve and the car is moving at cable speed.

To the frame holding the grip is applied an inverted rail,

which comes into contact with flat-faced pulleys on the tilting

frames of the sheaves which support the cable. This inverted rail

causes the movable sheaves to hold the cable at the proper height

to be received by the grip. The packing of the grips and sheaves

forming the contact surface for the cable is made of alternating

pieces of leather and India rubber. The packing is cut by machinery

and the pieces are put together under pressure. The composite

nature of the packing allows the leather to swell when moist and

to shrink when dry, the elasticity of the rubber keeping the packing

in proper shape.

Besides the hand brakes with which each car is provided, there

are vacuum brakes operated by connection with reservoirs carried

by the cars and exhausted of air by pumps operated by the eccentrics

on the car axles. The brakes have proved very efficient, the vacuum

being readily maintained by the pumps.

In the reconstruction of the propelling plant of the bridge

great credit is due to Mr. C. C. Martin, chief engineer and superintendent,

and to Mr. G. Leverich, assistant engineer, who have given to

every detail of the new plant the utmost care and attention. Nothing

has been omitted which would increase the efficiency of the machinery.

On the other hand, nothing has been introduced that is without

a practical bearing. The entire work has been done from plans

and specifications furnished by the engineers. The engines were

made by Mr. Wm. Wright, of Newburg, N. Y., as already stated.

The cable drums and machinery are from the works of the Southwark

Foundry and Machine Co., Philadelphia, Pa., and the clutches,

including their operating gear, from the works of Poole &

Hunt, of Baltimore, Md.

Brooklyn Bridge | Bridge Page

| Contents Page

|