|

Tractive Force and Hauling Capacity

The hauling capacity of a locomotive is determined by the relation

between the tractive force developed and the resistance of the

train, and both of these factors are dependent on the speed.

At starting speeds a locomotive will usually develop, at the

rim of the driving wheels, the rated tractive force, which is

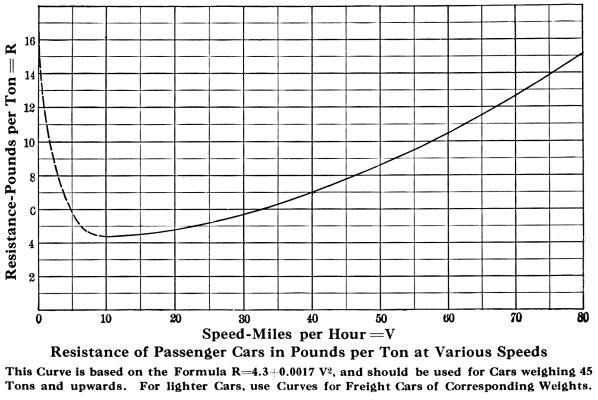

calculated from the dimensions of the engine by the formula:

where T=the rated tractive force at rim of driving wheels in

pounds.

P=the boiler pressure in pounds per square inch.

C=diameter of cylinders in inches.

S=stroke in inches.

D=driving wheel diameter in inches.

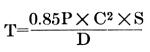

As the speed is increased the available tractive force falls

off slowly until a point is reached at which the boiler can no

longer supply the steam required by the cylinders at full stroke.

To attain higher speeds the cut-off must be shortened, after which

the available tractive force falls more rapidly. It is evident

that, under these circumstances, the tractive force that a locomotive

can develop is dependent not only on the cylinder and driving

wheel dimensions, but also on the steaming capacity of the boiler.

For practical purposes this may be taken as directly proportional

to the total heating surface. Then, as is shown by the curves

in next diagram, the available tractive force at any speed will

depend on the relation between the rated tractive force and the

total heating surface. Each curve corresponds to a different value

of this relation. The vertical scale measures the available tractive

force as a percentage of the rated tractive force, while on the

horizontal scale the speed is measured in miles per hour. The

curves assume that at the high speeds one horse-power can be developed

at the tread of the driving wheels for every two and one-half

square feet of heating surface, and they allow for a lower efficiency

at slow speeds.

In assuming as above that the steaming capacity is directly

proportional to the total heating surface, it is essential that

the ratio of grate area to heating surface be properly suited

to the quality of the fuel. It is also assumed that sufficient

fuel can be fired to enable the steam production to be pushed

to the limit set by the heating surface.

As an example of the use of the curves, suppose it is desired

to find the available tractive force at a speed of forty miles

per hour, for a locomotive having the following dimensions:

Cylinders, 22" x 28"

Driving wheels, 69" diameter

Steam pressure, 200 pounds

Heating surface, 4150 square feet

From the formula on the preceeding page, it is found that the

rated tractive force of this locomotive is 33,400 pounds. The

ratio of rated tractive force to heating surface is therefore

=8.0. Referring to the curve herewith, it is seen

that the vertical line representing 40 miles per hour intersects

the curve marked 8, on a horizontal line representing 47 per cent.

Hence, the tractive force developed by this locomotive at a speed

of 40 miles per hour, will be =8.0. Referring to the curve herewith, it is seen

that the vertical line representing 40 miles per hour intersects

the curve marked 8, on a horizontal line representing 47 per cent.

Hence, the tractive force developed by this locomotive at a speed

of 40 miles per hour, will be

33,400 x .47=15,700 pounds.

In order that a locomotive may employ all of its rated tractive

force in hauling a train, it is desirable that the weight on driving

wheels be at least 4 times the rated force; or, in other words,

not more than 25 per cent. of the adhesion weight can be utilized

as tractive force.

In the case of locomotives equipped with compound cylinders

or superheaters, the proportion of the rated tractive force developed

at any speed will be from 10 to 20 per cent. higher than that

shown by the curves.

Relation of Rated Tractive Force to Heating

Surface

Average values of the quotient obtained by dividing the rated

tractive force in pounds by the total heating surface in square

feet, for different classes of engines, are given below:

Atlantic (4-4-2) type, 8

Pacific (4-6-2) type, 9

American (4-4-0) type, 10

Mikado (2-8-2) type, 10

Ten-wheeled (4-6-0) type, 11

Consolidation (2-8-0) type, 14

Switching Locomotives, 16

Train Resistance

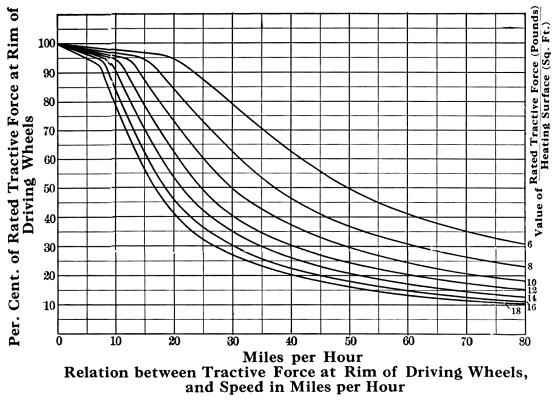

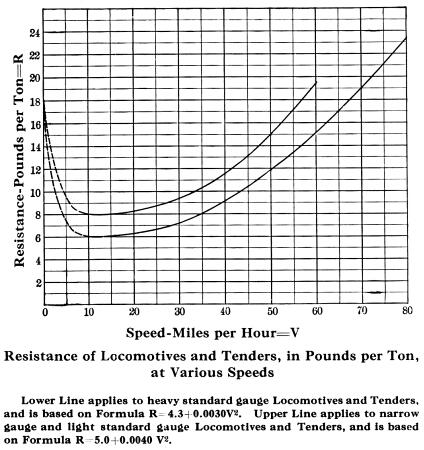

The chart herewith represents the resistance, in pounds per

ton, for freight cars of different weights, at speeds varying

from 5 to 40 miles per hour, on straight level track. These curves

are based on the results of experiments conducted by Prof. Edward

C. Schmidt, on the Illinois Central Railroad. Recent tests show

that the resistance of light cars is greater, in pounds per ton,

than that of heavy cars. Thus, a car weighing 75 tons is seen,

from the table, to have a resistance of 5 pounds per ton at a

speed of 35 miles per hour, while a car weighing only 20 tons

has a resistance of 11.1 pounds per ton at the same speed.

A formula which gives results approximately agreeing with the

curves, is as follows:

This formula is worked out for a speed of 5 miles per hour.

For higher speeds, add 2 per cent. for each mile per hour above

5. The formula should not be used for speeds exceeding 30 miles

per hour.

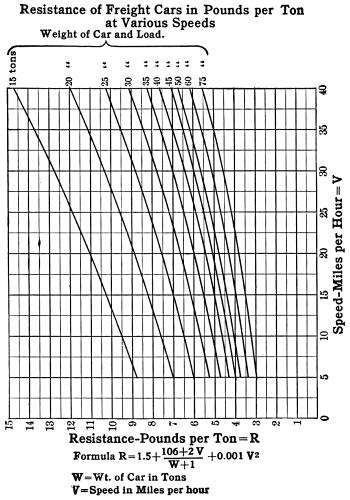

The resistance of passenger cars in pounds per ton on straight,

level track, is represented by the diagram herewith. The curve

here shown is based on the results of recent experiments with

modern rolling stock, and is applicable to cars weighing 45 tons

and upward. For lighter cars use the diagram on page 13, selecting

the line which applies to the particular weight of cars in question.

The diagram herewith, represents the resistance of the locomotive

and tender in pounds per ton. Two lines are shown, the lower one

being applicable to heavy standard gauge engines, and the upper

one to narrow gauge and light standard gauge engines. These curves

generally follow that for passenger cars, plus an amount sufficient

to cover the head end resistances.

The resistance due to grades is discussed a little further

on in this text.

Superheating

The temperature to which it is necessary to raise water before

it can be evaporated into steam, depends upon the pressure. For

every given pressure there is, therefore, a corresponding minimum

temperature at which steam can exist. Steam existing at this temperature

is said to be saturated, and any reduction in temperature will

cause some of the steam to be condensed as water. If the temperature

is above that of saturation the steam is said to be superheated.

A device employed for the purpose of raising the temperature of

steam above that of saturation, is called a superheater.

The temperature of the cylinder walls of a locomotive is constantly

changing, owing to the variation in the steam temperature due

to expansion. As a result there is considerable condensation of

steam, causing a loss in efficiency. The object in using superheated

steam is to reduce this loss, by raising the steam temperature

to such a point that condensation is, to a large extent, avoided.

Furthermore since the volume per pound of superheated steam is

greater than that of saturated steam at the same pressure, there

is a gain in efficiency, because each pound of water evaporated

forms a larger volume of steam, and therefore fewer pounds of

steam are required to fill the cylinders.

The type of superheater generally used in locomotive work is

known as the firetube. It is designed to give from 150 to 200

degrees of superheat, and in some cases even higher temperatures

are attained. The superheater pipes are placed in a number of

large tubes, which are about five and one-half inches in diameter.

These tubes, like the small boiler tubes, convey the products

of combustion from the firebox to the smokebox. A double loop

of superheater pipes is usually placed in each large tube, and

the pipes extend from the headers in the smokebox, to within a

short distance of the firebox. The hot gases passing through the

large tubes, both heat the water and superheat the steam. A damper

is usually placed in the smokebox to cut off the draft through

the large tubes when the throttle is closed. This is for the purpose

of preventing the burning out of the superheater pipes when no

steam is passing through them. The nature of the service to be

performed, size and type of locomotive, and various other factors,

must be considered when applying superheaters.

The locomotives described in the tables in this catalogue can

be designed to use superheated steam, provided operating conditions

are favorable. The superheater is of special value in heavy locomotives,

which must develop high horse-power for sustained periods of time.

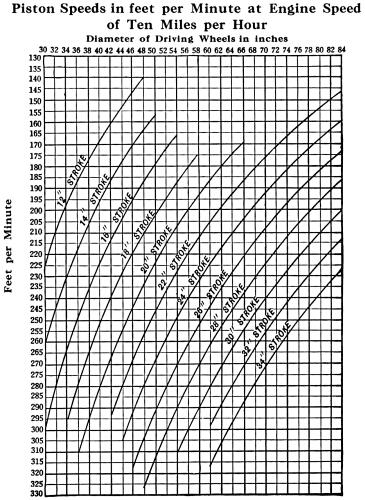

Piston Speed

The figures at the top of the chart herewith, represent the

diameter of the driving wheels in inches, and those at the left

hand side indicate the piston speed in feet per minute. The several

curves in the body of the chart represent different strokes of

piston.

Follow the perpendicular line from the number representing

the diameter of wheel selected until it intersects the curve representing

the desired stroke; then follow the horizontal line from the point

of intersection to the left hand margin, and the figure here given

will denote the piston speed.

It will be noted that the calculations are based on an engine

speed of ten miles per hour. Greater speed will be determined

by multiplying the results by the proper factor indicated by the

speed required. In locomotive practice the maximum piston speed

should not exceed 1600 feet per minute. The economical speed may

be placed at about 1100 feet per minute.

Horse-Power

The term horse-power was first established by James Watt, who

ascertained that a strong London draught. horse was capable of

doing work for a short interval of time equivalent to lifting

33,000 pounds through a height of one foot in one minute.

This value was used by Watt in expressing the power of his

engines, and has since been universally adopted in mechanics.

The unit of work is the foot-pound, which is the amount of work

required to lift a weight of one pound through a space of one

foot.

Horse-power is the measure: of the rate at which work is performed,

and is equal to 33,000 pounds lifted one foot in one minute, or

one pound lifted 33,000 feet in one minute, or one pound lifted

550 feet in one second; therefore, one horse-power equals 550

foot-pounds per second.

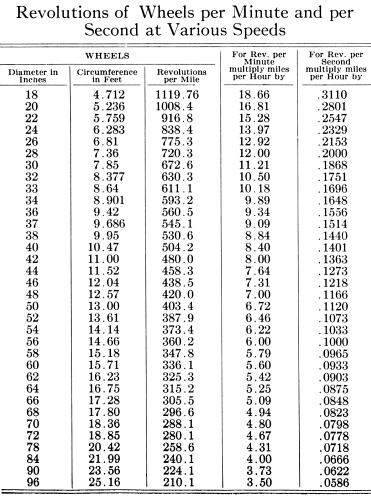

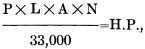

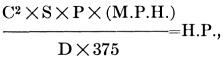

The general formula for ascertaining the horsepower of a locomotive

is as follows:

in which

P=mean effective pressure in pounds per square inch.

L=length of stroke in feet.

A=area of the piston in square inches.

N=number of strokes (four times the number of revolutions) per

minute.

H. P.=indicated horse-power.

By cancellation and substituting the diameter of the driving

wheels, the formula may be reduced to the following:

in which

C=diameter of cylinder in inches.

P=mean effective pressure at given speed.

S=length of stroke in inches.

M. P. H.=miles per hour.

D=diameter of driving wheels in inches.

H. P.=horse-power.

The tractive force of a locomotive, multiplied by the speed

in miles per hour, divided by 375, gives horse-power.

Grades

When a train is hauled up a grade, the resistance due to friction

is increased by that due to lifting the train against gravity.

One mile equals 5280 feet; hence a ton of 2000 pounds raised one

foot in one mile, represents a resistance of  or .3788

pounds. Therefore, when the grade is expressed in feet per mile,

the number of feet multiplied by .3788 gives the resistance in

pounds per ton of 2000 pounds. When the grade is expressed in

feet per hundred or per cent., the per cent. of grade multiplied

by twenty gives the resistance in pounds per ton of 2000 pounds. or .3788

pounds. Therefore, when the grade is expressed in feet per mile,

the number of feet multiplied by .3788 gives the resistance in

pounds per ton of 2000 pounds. When the grade is expressed in

feet per hundred or per cent., the per cent. of grade multiplied

by twenty gives the resistance in pounds per ton of 2000 pounds.

The resistance due to friction must, of course, be added to

that due to the grade, in order to find the total resistance of

the train.

The accurate method of determining a grade is by means of surveyor's

instruments, but if these are not available the following method

will suffice, unless the inclination is very moderate. A straight

edge, 100 inches long, with one end resting on the rail, is leveled

by means of a spirit level; and the vertical distance between

the other end of the straight edge and the rail is measured. This

distance expressed in inches, equals the grade in per cent.; and

when the inclination is at all steep the result so obtained is

fairly accurate.

Curves

In the United States it is customary to express curvature in

degrees noted by twice the deflection from the tangent measured

at stations 100 feet apart. In other words, the number of degrees

of central angle subtended by a chord of 100 feet represents the

"degree curve." One degree of curvature is equal to

a radius of 5730 feet. Therefore, the number of degrees divided

into 5730 gives the radius in feet, or, per contra, the number

of feet radius divided into 5730 gives the number of degrees.

This assumes that the 100 feet are measured on the arc instead

of the chord, but the error is so slight on curves commonly used

that it may be ignored for ordinary calculation.

In Great Britain it is common to define a curve as so many

chains (sixty-six feet) radius. Thus the radius of a one degree

curve expressed in chains would be  =86.81; therefore,

86.81 divided by the degrees equals the radius in chains; or 86.81

divided by the radius in chains equals the degrees. =86.81; therefore,

86.81 divided by the degrees equals the radius in chains; or 86.81

divided by the radius in chains equals the degrees.

In the metric system instead of the stations being 100 feet

apart they are taken at twenty metres (65.61 feet). The central

angle remaining the same, the radius must necessarily be less.

This is represented by  for a one degree curve, or

approximately five-eighths, English measurement, which can be

used as a factor for converting the English to the French system. for a one degree curve, or

approximately five-eighths, English measurement, which can be

used as a factor for converting the English to the French system.

The resistance due to curves averages from 0.7 to 1.0 pound

per ton per degree of curvature, depending upon weight of cars,

condition of track, etc.

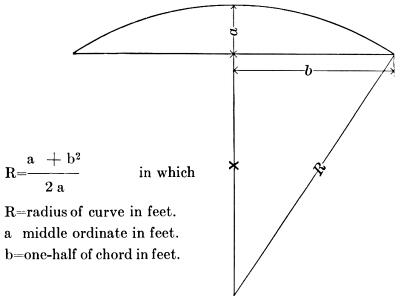

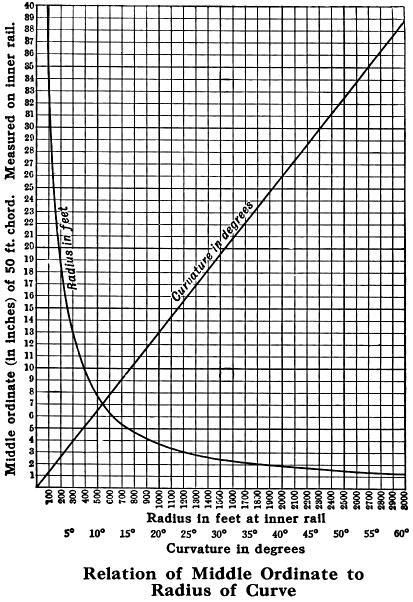

Radius of Curves

To determine the radius of any existing curve, lay off carefully

on the inside rail, by any convenient means, a chord of any desired

length, as shown in the accompanying diagram. Note the center

height or middle ordinate of the chord (a) in feet or fraction

of a foot. The formula is as follows:

A simple method for approximately measuring the degree of curvature

is as follows: Let the chord equal two rail lengths, then half

the chord, or measurement b, will be approximately thirty feet,

and the height of the middle ordinate a in inches will nearly

equal the curvature in degrees.

The diagram herewith, gives the radius in feet, and the curvature

in degrees, for ordinates from one to forty inches measured on

a chord of fifty feet in length.

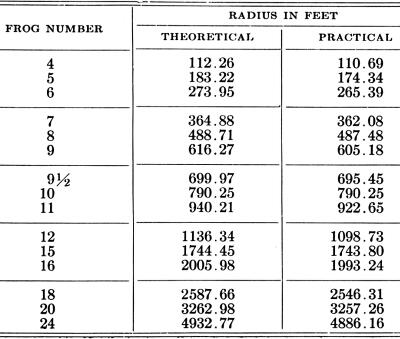

Radii of Curves at Switches

The following table, compiled from the Manual of the American

Railway Engineering Association (1915), gives the radii of curvature

at point switches using different frogs. In each case the switch

is supposed to lead from a tangent, and the radius is measured

to the center of the track:

The theoretical radii are mathematically computed. In order,

however, to reduce rail cutting and rail waste, it is usually

desirable to use the "practical" instead of "theoretical"

radius; as the straight lead rail is then of a length to permit

the eventual utilization of both pieces into which a rail is cut.

Gauge of Track

The measurement for track gauge is understood to represent

the distance between the inside edges of the heads of the rails,

as shown in the accompanying sketch, and the distance over the

flanges represents the gauge less the required amount of play

or clearance between the flange of the wheel and the rail.

When deciding the gauge for a contemplated road, the following

suggestions will be found useful:

If the line is to connect with any standard gauge road, the

track should correspond and be of the standard broad gauge, which

is four feet eight and one-half inches.

If such connection is unlikely and narrow gauge is considered

preferable, the standard narrow gauge should be adopted, which

is three feet.

The advantage of adopting one of these standard gauges, is

that, should it be desirable at any time to sell the equipment,

a ready market can be found.

For logging railroads the standard gauge of four feet eight

and one-half inches is generally preferable, as the cars can then

have long bolsters and be heavily loaded without piling the logs

too high.

While some roads use the same gauge in curves as on tangents,

it is desirable in order to insure easy riding and reduce wear,

to widen the gauge in the curves. It is stated in "Trautwine's

Engineer's Pocket Book," that the gauge is usually widened

by from one-thirty-second inch to one-eighth inch for each degree

of curvature, the maximum amount seldom exceeding one inch.

Rails

The number of driving wheels required is determined by the

weight which they must necessarily carry and the strength of the

rail or permanent way. As an approximate calculation it may be

assumed that steel rails, properly supported by crossties, can

sustain, as a maximum, a weight per wheel of 225 to 300 pounds

for each pound per yard of rail. It is, therefore, easy to ascertain

the load which any given rail section will support.

Example. With a rail section of forty pounds per yard

the maximum weight for each wheel will be 40 x 300 =12,000 pounds.

This with a locomotive having two pairs of driving wheels will

equal an available weight on driving wheels of 48,000 pounds,

or with three pairs of driving wheels, of 72,000 pounds.

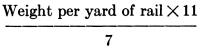

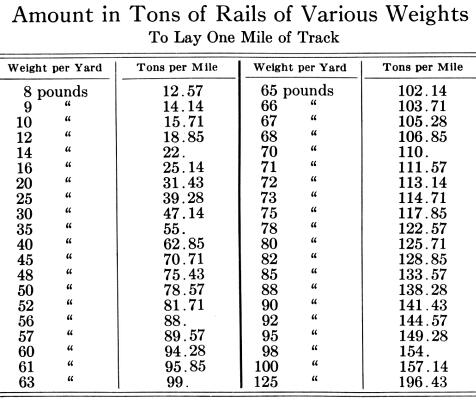

To ascertain the weight of rails per mile of single track to

be laid of any given section, the following formula may be used:

=Tons of 2240 pounds =Tons of 2240 pounds

Example. For a road equipped with 40-pound rails the

number of tons required per mile will be:

The following table is deduced from the above formula:

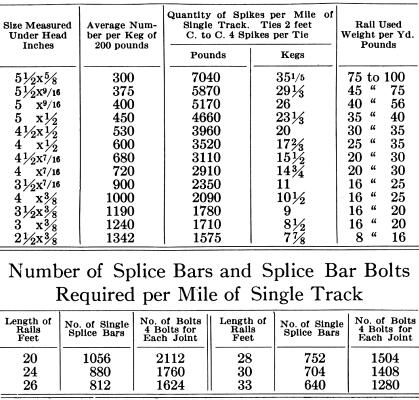

Spikes

The following table, giving data referring to railroad spikes,

is taken from the hand book of the Cambria Steel Company, Johnstown,

Penna.

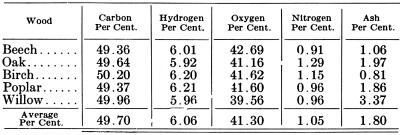

Crossties

A crosstie 9 x 7 inches and 8½ feet in length contains

3.719 cubic feet. If placed two feet apart, from center to center,

it will take 2640 per mile. If placed 2½ feet, 2112; and

if placed 3 feet, 1760 per mile will be required.

Fuel Consumption

Assuming that one-half stroke cut-off represents the average

work of the cylinders for a given run, the water consumption will

be about twenty-five pounds or three gallons per horsepower per

hour, and the consumption of coal about one pound per gallon of

water or three pounds per horse-power.

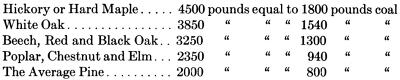

Wood as Fuel

On logging railroads wood is frequently used as fuel for locomotives.

The following data regarding the heating value and composition

of various woods has been selected from "Kent's Mechanical

Engineer's Pocket Book."

HEATING VALUE of WOOD-The weight of one cord of wood (thoroughly

air dried) is about as follows:

From the above it is safe to assume that two and one-quarter

pounds of average dry wood are equal to one pound of the average

quality of soft coal, and that the fuel value of the same weight

of different woods is very nearly the same—that is a pound

of hickory is worth no more for fuel than a pound of pine, assuming

both to be dry. It is important that the wood be dry, as each

ten per cent. of water or moisture in wood will detract about

twelve per cent. from its value as fuel.

The following table gives the composition of several kinds

of wood:

Smoke Stacks

The Radley and Hunter stack has been extensively used on wood

burning locomotives, and has proved to be a most efficient spark

arrester. This stack is provided with a straight inside pipe,

over which is placed a cast iron cone having volute flanges on

its under side. The outside casing of the stack is balloon shaped.

It has a diameter at the bottom 5 to 8 inches greater than the

inside pipe, with a maximum diameter approximately four times

that of the inside pipe. The sparks are given a rotary motion

when they strike the cone, and are broken up and extinguished.

Such refuse as does not escape to the atmosphere, falls to the

bottom of the outside casing, and is removed through a cleaning

hole. As a further precaution, netting is provided, through which

the products of combustion must pass before escaping from the

stack.

In some instances wood burning locomotives are fitted with

a straight open stack. An extended smokebox, equipped with fine

netting and deflecting plates, should then be used.

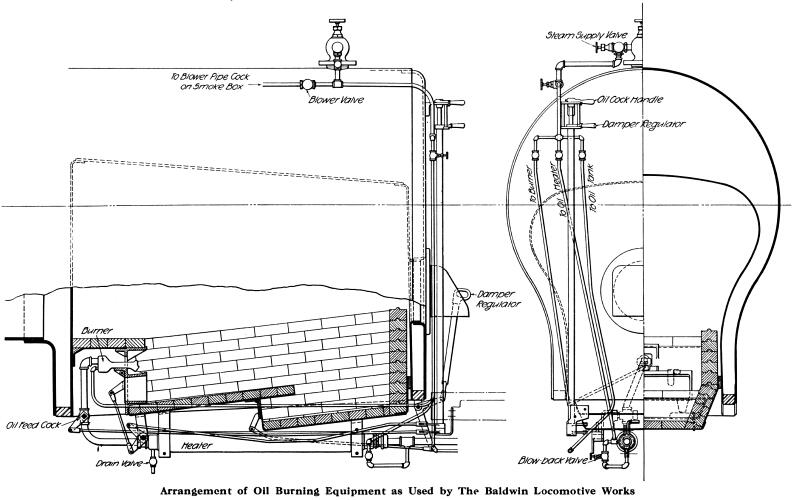

Oil Fuel for Locomotives

The development, during the past twenty years, of oil fields

in this country as well as abroad, has greatly increased the available

supply of petroleum for fuel purposes, and has in some districts,

resulted in the extensive introduction of oil burning locomotives.

Petroleum possesses certain advantages which render its use desirable

where it can be obtained at less cost than other forms of fuel.

One pound of oil possesses nearly as much heating power as two

pounds of coal, and probably as much as four pounds of wood, and

the ease with which the fuel may be handled and the fire regulated

to suit conditions of working, results in considerable economy

where an abundant supply is available.

A convenient arrangement of apparatus, which has been extensively

used for burning fuel oil, is shown in the accompanying illustrations.

The burner is located in the front of the firebox, and dampers

for the admission of air are placed beneath it and at mid-length

in the firepan. It is essential to have an arrangement that will

break up and atomize the oil, as without these conditions the

combustion will not be complete, and smoke and loss of economy

will result. The burner is rectangular in cross section with two

separated ports or chambers (one above the other) running its

entire length. Into the upper of these ports the oil is fed through

suitable pipes. Steam is admitted to the lower part of the burner

through a pipe connected to the boiler, and as the oil flows out

it is met by the jet of steam which atomizes it and sprays it

into the fire box. The flow of oil is regulated by a plug cock

in the feed pipe, provided with an operating handle placed within

easy reach of the fireman. The arrangement of the fire bricks

and firepan is clearly shown in the sections through the firebox.

A proper regulation of the quantity of air admitted through the

dampers is of importance, in order to secure perfect combustion,

and the dampers are arranged to close air tight and have substantial

rigging to operate them. The fire door is also air tight and is

provided with a peep hole for observing the condition of the fire.

But little change is necessary in the construction of the tender,

the oil tank being placed in the fuel space. Means are provided

for discharging steam into the oil tank, in order to keep the

fuel sufficiently liquid to flow readily; and an auxiliary heater

is usually placed in the pipe line leading to the burner.

The best adjustment of the diaphragm plates in the smokebox,

and of the regulating plate for the steam jet in the burner, is

found by experiment, and further change of these parts need not

be made except for cleaning or repairs. If the apparatus is in

wood working condition, engines after standing all night with

stack covered, and dampers closed, will have sufficient steam

pressure in the morning to spray the oil jet properly so that

the burner can be lighted.

Qualities of Coal

In designing locomotives for burning a particular quality of

coal, the question is likely to arise as to what is anthracite

or what is bituminous. The division between the different grades

is largely empirical. That given by Kent has been adopted as generally

satisfactory and is as follows:

ANTHRACITE—all coal with less than 7.5 per cent. volatile

matter in combustible.

SEMI-ANTHRACITE—all coal with 7.5 per cent. to 12.5 per

cent. volatile matter in combustible.

SEMI-BITUMINOUS—all coal with 12.5 per cent. to 25 per cent.

volatile matter in combustible.

BITUMINOUS—all coal with 25 per cent. to 50 per cent. volatile

matter in combustible.

LIGNITE—all coal with more than 50 per cent. volatile matter

in combustible.

When coal is of a doubtful quality a sample can be forwarded

for analysis and specifications will be furnished for locomotives

guaranteed to meet requirements and burn the coal to advantage

if practicable.

Logging Service

For logging service the standard gauge of four feet eight and

one-half inches is generally preferable. It is found economical

to use steam power even where the output is comparatively small

and the distance covered is short. It is estimated that under

ordinary conditions the total cost of hauling by steam power including

interest and depreciation is from 30 to 60 cents per 1000 feet

of lumber cut.

Plantation Service

Locomotives used in plantation service are usually narrow gauge.

Sugar cane and other products are handled by steam power in a

large number of plantations in the United States, West Indies,

Mexico, Central and South America, Hawaii and the Philippines.

Industrial Service

For use in steel and blast furnaces and other manufacturing

establishments locomotives have become indispensable. They can

be operated if necessary for twenty-four hours per day without

serious inconvenience, and by their use the work is accomplished

in a more economical manner than by any other form of power. For

shifting cars from main lines to factory yards, where power belonging

to the railroad company is not always available, it is often found

more economical to install locomotives to prevent unavoidable

delays.

Contractors' Service

In moving material for railroad or other excavations, locomotives

can be adapted to run on light, temporary track which is easily

shifted, and thus do the work at a cost far below that which would

be incurred if animal power were used. Besides this, a great saving

of time is made, which in work of this description is generally

of the utmost importance.

Coke Ovens

For feeding coke ovens the steam locomotive furnishes the most

economical and satisfactory power.

Mine Service

It is frequently more convenient with the output of the mine,

either coal or ore, to make delivery in mine cars at the point

of shipment without breaking bulk. To do this locomotives are

required of a gauge corresponding to that of the mine car.

In some instances these locomotives are required to run in,

as well as about, the mine; in which case they must be adapted

for use underground and conform in height and width to the dimensions

of the gallery in which they are to operate.

Cable Codes

The cable address is "Baldwin, Philadelphia." Each

of the following tables has a code word in the line opposite the

class numbers, the use of which indicates that a locomotive of

the class and general dimensions shown on the line referred to

is required. The following codes are used: Lieber's; Al; A-B-C,

fourth and fifth editions; Western Union; Vanguard; Commercial

Code (Atlantic Cable Code), and The Baldwin Locomotive Works Private

Code.

Locomotive Types

Class

Designation

Four Coupled Switching

Type 0-4-0 Type 0-4-0

Four coupled switching locomotives have all the weight on the

driving wheels, and are suitable for contractors' or industrial

service, and also for light switching work in railroad yards and

terminals. These engines have short wheel bases, and they can

be safely operated on sharp curves and switches. The smaller classes

can easily traverse curves of fifty feet radius. For short runs,

or for switching service where a large fuel and water supply are

not required, saddle or side tanks can be used and the fuel carried

in the cab or on a rear extension of the engine frames. For longer

runs, a separate tender should be employed. If desired, the tender

tank is made with a sloping back, thus giving the enginemen a

better view when backing up. A separate tender is also an advantage

on exceptionally narrow track, as it admits of a lower center

of gravity than if the tank were placed on the boiler.

In the tank-frame locomotives, the frames consist of steel

plates, between which the water tank is placed. This construction

lowers the center of gravity; an important feature where the gauge

is unusually narrow. These engines are fitted with a simple design

of Marshall valve gear, having all its parts outside the wheels

where they are easily accessible. This style of gear has had a

thorough trial on light industrial locomotives operating under

the most severe service conditions.

Four Coupled with Two-Wheeled Front

Truck

Type 2-4-0

Four coupled locomotives, with two-wheeled leading trucks,

are suitable for service where the runs are short and the speed

moderate. Two pairs of wheels are equalized together, either the

driving wheels with each other or the front pair of driving wheels

with the pony truck.

The truck has a swinging bolster and radius bar. Engines of

this type readily traverse curves of short radius. A separate

tender is usually provided, but if the run is short these locomotives

can be designed with either saddle or side tanks.

Four Coupled with Two-Wheeled Rear

Truck

Type 0-4-2

This type is particularly serviceable for operating short lines,

where limited water and fuel capacity will answer. These locomotives

have their driving wheels equalized together, the truck being

center-bearing, with swinging bolster and radius bar. Having a

comparatively long total wheel base and a short rigid wheel base,

they are steady, and ride smoothly without plunging, curve readily,

and cause little wear of track. The fuel is carried on the engine

frames at the back; the water is carried either in saddle or side

tanks, or in a tank back of the cab. The latter plan is better

for light rails. If the tank is placed on the boiler, its weight

adds to the adhesion and increases the hauling capacity, greater

space is afforded the enginemen in the cab, and a larger supply

of fuel may be carried. The weight is well distributed, the principal

portion being carried on equalizing levers between the driving

wheels, thus affording an equal distribution on these wheels.

The pony truck carries the weight of the fuel or the fuel and

water, as the case may be, with a part of the weight of the overhanging

firebox. These locomotives are well adapted for running in either

direction.

American Type

Four Coupled with Four-Wheeled Front Truck

Type 4-4-0

American type locomotives, having four coupled wheels and a

four-wheeled leading truck, are suitable for passenger, freight

and mixed service, where the run is of such length as to require

a separate tender, or for short lines intended ultimately to be

extended. The name "American" type was given for the

reason that for many years locomotives of this type were used

more than any other, for nearly every variety of service throughout

the United States.

Forney Type

Four Coupled with Four-Wheeled Rear Truck

Type 0-4-4

Forney type locomotives, having two pairs of coupled wheels

and a four-wheeled rear truck, are compact and powerful for their

aggregate weight, and are suitable where the run is not long enough

to necessitate a separate tender. The constant weight of the boiler

and machinery is on the driving wheels, while the variable weight

of fuel and water is on the truck. Locomotives of this type are

used as double-enders, being run with equal facility forward or

backward. The driving wheels are equalized together; the truck

is center-bearing and has a swinging bolster. These locomotives

readily traverse curves of short radius. Standard gauge locomotives

of classes 8-161/3-C and 8-181/3-C

have been used on curves of ninety feet radius in passenger service.

The fuel and water are carried at the rear of the cab.

Four Coupled Double-Ender

Types 2-4-2- and 2-4-4

Locomotives having four coupled wheels and a truck at each

end, are suitable for logging, industrial or light road service.

These engines ride steadily on uneven tracks, and can be safely

run in either direction. They are built with saddle, side, or

rear tanks; or, if the runs are long, separate tenders may be

used. As a rule, both the front and rear trucks have two wheels;

but if the tank is placed back of the cab, on an extension of

the engine frames, a four-wheeled rear truck should be used. When

both trucks have two wheels, the front is center bearing and is

equalized with the first pair of driving wheels; while the rear

truck is side-bearing, and is equalized with the second pair of

driving wheels.

The following pages present series of narrow and standard gauge

locomotives with saddle or side tanks, and of standard gauge locomotives

with rear tanks and with separate tenders.

Atlantic Type

Four Coupled with Four-Wheeled Front Truck

and Trailing Wheels

Type 4-4-2

Locomotives of this type are particularly suitable for high-speed

passenger service. The driving wheels are located under the waist

of the boiler, and the front end of the engine is carried on a

four-wheeled truck. A firebox having ample grate area and volume

is placed back of the rear driving axle, and the overhanging weight

is carried by a pair of trailing wheels. This arrangement provides

a boiler having large steaming capacity in proportion to the adhesion-an

essential feature of a high-speed locomotive.

In locomotives of this type the firebox may be placed entirely

back of the driving wheels if desired, thus allowing an increased

width of furnace. The trailing wheels may be placed in a radial

truck, or may be held in rigid pedestals. In either case, these

wheels are equalized with the driving wheels. The leading truck

is provided with a swing bolster, and all the wheels under the

locomotive have flanged tires. The compact grouping of the driving

wheels permits the use of short coupling rods, thus reducing the

liability of breakage when running at high speed.

Six Coupled Switching

Type 0-6-0 Type 0-6-0

Locomotives of this type are more generally used for switching

service than any other. They are also suitable for heavy contractors'

service, and for industrial work about mills, furnaces and large

manufacturing plants. Tank locomotives of this type are suitable

for short runs, and for switching work where large fuel and water

capacity are not required. Ordinarily, however, a separate tender

is to be preferred; especially with the heavier classes of narrow

gauge engines, where the use of saddle or side tanks may raise

the center of gravity too high. In the case of heavy standard

gauge engines also, it is difficult to secure adequate fuel and

water capacity without using a separate tender.

Mogul Type

Six Coupled with Two-Wheeled Front Truck

Type 2-6-0

The Mogul type, with three pairs of coupled wheels and

a two-wheeled leading truck, is primarily designed for road service,

and is suitable where the eight-wheeled or American type would

not afford sufficient power, or where the requisite weight on

the driving wheels, if carried on only two pairs, would be greater

than the rails could safely bear. The front and rear driving wheels

are always flanged, while the middle pair usually has no flanges.

The pony truck has a swinging bolster and radius bar. The plans

illustrated show:

First.—A locomotive with a deep firebox between the middle

and rear driving axles. This design has the advantage of giving

ample depth of firebox, but necessitates a greater spread of wheels

than is admissible in some instances.

Second.—A locomotive with a firebox placed above the frames

and over the rear axle. This design admits of the driving wheels

being grouped closely together. It answers well where coal is

the fuel, but where wood is burned a deep firebox is desirable.

Third.—A locomotive with the driving wheels grouped closely

together and a firebox placed entirely back of them. The depth

of firebox is sufficient for burning either wood or coal. The

short driving wheel base admits of traversing curves of short

radius. Connection to the tender is made by means of a radial

drawbar passing through the ash pan.

Six Coupled with Two-Wheeled Rear Truck

Type 0-6-2

Six coupled locomotives, with two-wheeled rear trucks, are

suitable where the runs are not long enough to require a separate

tender. The addition of a truck avoids the uneven motion to which

short wheel base locomotives, with a long overhang, are subject.

The increased space back of the cab permits of greater coal

capacity and more room for the enginemen than is practicable without

the truck. The three pairs of driving wheels are equalized together;

the truck is center bearing, and has a swinging bolster and radius

bar.

Ten-Wheeled Type

Six Coupled with Four-Wheeled Front Truck

Type 4-6-0

The ten-wheeled type, having three pairs of coupled wheels

and a four-wheeled front truck, is suitable where a locomotive

of the American type would not afford sufficient power, or where

the requisite weight, if carried on only two pairs of driving

wheels, would be greater than the rails could safely bear. The

greater length of these locomotives admits of a longer boiler,

with increased heating surface as compared with the American type.

The front and rear driving wheels are preferably flanged, and

the truck made with swinging bolster. The main driving wheels

are made with either plain or flanged tires, according to service

requirements.

Three plans of standard gauge locomotives are shown, viz.:

First.—With firebox between the main and rear driving

axles.

Second.—With firebox above the rear driving axle.

Third.—With firebox above the rear pair of driving wheels.

The last arrangement is particularly suitable for heavy engines,

as a large grate area can be provided without using an excessively

long firebox.

Six Coupled Double-Ender

Type 2-6-2 Type 2-6-2

Six coupled double-ender locomotives, with two-wheeled front

and rear trucks are suitable where it is desired to run forward

or backward without turning, and where the weight required for

adhesion cannot be carried on two pairs of wheels without overloading

the rails.

The front truck is equalized with the front pair of driving

wheels, and the rear truck with the middle and rear pairs of driving

wheels. The front truck is center-bearing, the rear truck is side-bearing.

Each truck has a swinging bolster and radius bar. This arrangement

enables the engine to ride smoothly, and each wheel finds a bearing

on the most uneven track. The middle pair of driving wheels has

plain tires. A saddle tank covering the boiler or two rectangular

tanks, as illustrated, can be used.

For longer runs a separate tender is provided. A large number

of engines of this type have been built for logging roads, and

in such service they are giving most satisfactory results.

Pacific Type

Six Coupled with Four-Wheeled Front and

Two-Wheeled Rear Trucks

Type 4-6-2

The Pacific type is a high-powered design, having three pairs

of driving wheels grouped under the waist of the boiler, a four-wheeled

front truck, and a two-wheeled rear truck.

The firebox is placed back of the rear driving wheels, and

the overhanging weight is supported by the rear truck. The result

is a locomotive having ample adhesion weight and tractive force,

together with a boiler of high steaming capacity, thus enabling

the engine to haul heavy loads at sustained speeds.

The rear trucks can be designed with either inside or outside

journals. They are equipped with radius bars, and are equalized

with the driving wheels; by which means a flexible wheel base

is obtained.

Pacific type locomotives are specially suitable for heavy,

fast passenger service, and are also proving successful in fast

freight service.

Eight Coupled Switching

Type 0-8-0

This type of locomotive is suitable for heavy switching service,

where the weight necessary for adhesion is too great to be safely

carried on three pairs of wheels. Such requirements are found

in hump yards, where locomotives of high tractive force are needed

to push trains over the hump; also in heavy terminal and transfer

service, and to a lesser extent in industrial work, or for general

switching purposes where the engines must operate on light tracks.

Separate tenders are preferably used with locomotives of this

type.

Consolidation Type

Eight Coupled with Two-Wheeled Front Truck

Type 2-8-0

The Consolidation type has four pairs of driving wheels and

a two-wheeled front truck, and is specially suitable for heavy

freight service. A large percentage of the total weight of the

locomotive is available for adhesion; and as this weight is distributed

over four pairs of driving wheels, a high tractive force can be

developed without using excessive wheel loads. The front and rear

pairs of driving wheels are flanged, while the intermediate pairs

have either plain or flanged tires according to service requirements.

The truck has a swinging bolster and radius bar.

Ordinarily in this type a long firebox is placed over the rear

driving axle, and is especially adapted for burning coal. In some

instances such engines have been satisfactorily used for burning

wood. A plan for narrow gauge locomotives is also presented in

which a deep firebox overhangs the rear driving wheels. The driving

wheel base is shorter than in engines of the first mentioned type,

because the wheels are placed as close together as possible under

the waist of the boiler. In this design there is ample depth between

the tubes and the grate for the combustion of wood, while the

same plan answers equally well for bituminous coal.

The heaviest classes of standard gauge engines are preferably

built with the grate placed above the rear pair of driving wheels.

This plan provides sufficient grate area, without using a furnace

of excessive length. The tables include a series of engines so

arranged.

Mikado Type

Eight Coupled with Two-Wheeled Front and

Rear Trucks

Type 2-8-2

This type of locomotive is a development of the Consolidation.

The two-wheeled rear truck permits the use of a wide and deep

firebox, which is placed back of the driving wheels. This increases

the steaming capacity in proportion to the adhesion, making these

engines specially suitable for heavy freight service, where long,

hard runs must be made. Owing to the liberal space available for

the firebox, these locomotives can readily be designed to use

inferior grades of fuel; and on several roads they are burning

lignite successfully and economically.

Mikado type locomotives, having a truck at each end, are able

to back into sharp curves and switches without danger of derailment;

and for this reason are proving highly successful in heavy service

on logging and industrial railways. This class of work frequently

requires heavy hauling in addition to switching; and the combination

of excellent steaming and tracking qualities, as found in the

Mikado type, makes it particularly suitable for such service.

Mountain Type

Eight Coupled with Four-Wheeled Front and

Two-Wheeled Rear Trucks

Type 4-8-2

This type is especially suitable for heavy express passenger

service on steep grades, where the necessary tractive force cannot

be developed by a six coupled locomotive. The four-wheeled front

truck provides excellent guiding qualities, and the driving-wheels

can be made of sufficient diameter for fast running. The boiler

is of large diameter, and has a deep, wide firebox, with ample

grate area and furnace volume. This provides high steaming capacity

in proportion to adhesion; an essential feature in heavy passenger

service.

These locomotives are also suitable for fast freight service

on divisions having comparatively light grades, where heavy trains

must be moved at fairly high speeds.

Santa Fe Type

Ten Coupled with Two-Wheeled Front and

Rear Trucks

Type 2-10-2

Ten coupled locomotives are suitable for heavy freight service,

where the weight necessary for adhesion cannot be carried on four

pairs of driving wheels without overloading the rails. The Santa

Fe type is a development of the Mikado, and, like it, has a two-wheeled

rear truck, allowing room for a wide and deep firebox placed back

of the driving wheels. Locomotives of this type have high steaming

and hauling capacity, and have been built to traverse curves of

sixteen degrees, or even, in some cases, of shorter radius. The

tires on the middle pair of driving wheels are usually made without

flanges. The Santa Fe is the largest type of locomotive thus far

produced, in which all the driving wheels are coupled in one group.

Mallet Articulated Locomotives

The Mallet articulated type employs compound cylinders and

two groups of driving wheels. The rear group is driven by the

high pressure cylinders and the forward group by the low pressure.

The rear frames are held in rigid alinement with the boiler, while

the front frames can swing about a hinge pin located on the center

line of the engine between the high-pressure cylinders. The forward

group of wheels thus constitutes a truck, giving sufficient flexibility

to the wheel-base to enable the locomotive to easily traverse

sharp curves. The receiver pipe between the high and low pressure

cylinders, and the exhaust pipe from the low-pressure cylinders

to the smoke-box, are necessarily provided with flexible joints.

These pipes carry low pressure steam only, hence the joints can

be kept tight without difficulty.

Superheaters have been applied to a large number of Mallet

locomotives, with most satisfactory results. The heater is placed

between the throttle and the high pressure cylinders, and sufficient

superheat is obtained to avoid difficulties due to condensation

in the low pressure cylinders.

Mallet locomotives are specially suitable for pushing service,

and for road service where grades are steep, speeds moderate,

and operating conditions unusually severe. They are also fitted

for switching service in hump yards, where heavy trains must,

be pushed up one side of the hump before being classified.

Modifications of the wheel arrangements can, if necessary,

be made to suit special conditions.

Triple Articulated Compound Locomotives

This type is a development of the Mallet. It has three groups

of driving wheels, two placed under the boiler and the third under

the tender. The cylinders of the middle group of wheels are the

high-pressure, and these exhaust simultaneously into the front

and back cylinders. All the cylinders are of the same size, and

are cast from the same pattern; hence the ratio of compounding

is as one to two. The exhaust from the front cylinders is utilized

to create a draft for the fire, while that from the rear cylinders,

after passing through a feed-water heater, is discharged up a

pipe at the rear of the tank. The boiler is held in alinement

with the frames of the middle group of wheels, and the front and

rear frames are hinged to the middle frames. With this construction

these locomotives traverse curves without difficulty. Front and

rear trucks have been applied to all the triple locomotives thus

far built.

These engines, with a large percentage of total weight on driving

wheels, are especially suitable for heavy pushing service where

high tractive force must be developed at comparatively slow speeds.

Fireless Locomotives

These locomotives are specially suitable for switching service

where fire risks must be absolutely eliminated. In place of a

boiler, this type is fitted with a cylindrical tank which is charged

with steam and hot water from a stationary plant. The storage

pressure usually approximates the working pressure of a locomotive

boiler; but the pressure of the steam is considerably reduced

before it enters the cylinders. As the steam is drawn from the

storage tank, the pressure in the latter becomes reduced. When

this occurs, however, a portion of the stored water evaporates,

and the steam supply can thus be maintained until the storage

pressure drops to the cylinder working pressure. The locomotive

should then be recharged. The cylinder proportions are such, however,

that the locomotive can move itself on very much less than the

normal working pressure.

In charging, steam is admitted at the bottom of the reservoir

through a perforated pipe, so that the temperature of the entire

body of water is gradually raised.

These locomotives are simple in construction and, as they cannot

explode, they are exceedingly safe to handle. As a rule, but little

equipment must be installed for their operation, as the majority

of industrial plants are supplied with the boiler capacity necessary

for charging the locomotives.

Contents Page

|