|

FOREWORD

THE Climax Patent Geared Locomotive is now in successful

operation in almost every part of the civilized world. When it

is remembered that it is only ten years since this improved type

of engine was placed on the market, its success must be regarded

as the best, evidence of its superior worth. The great and increasing

demand for this engine has necessitated the increasing from time

to time of facilities on the part of the manufacturers, in the

way of new buildings and special tools and machinery, until today

their equipment is complete in every detail. The Climax Patent

Geared Locomotive is made upon the most modern and approved principles,

its center gearing, which is peculiar to this type of engine,

furnishing and maintaining an equal distribution of power to both

rails.

The design of this catalogue is twofold. First, to illustrate

the superior construction of this locomotive, and, second, to

show a number of views of the engine taken while in operation,

all of which tell their own story of efficiency and ability to

perform its task under the most difficult conditions. We have

thought it best to show these illustrations in preference to printed

testimonials, of which we have hundreds on file in our office,

copies of which we shall be pleased to furnish on application.

The matter of greatest importance to a purchaser of a locomotive

of our type is to know that he is getting the best. We fully guarantee

the Climax Patent Geared Locomotive, both for workmanship and

material, and invite a thorough investigation of its merits. An

impartial trial will demonstrate its worth. Estimates and full

particulars are cheerfully furnished on any size or type desired.

Yours respectfully,

CLIMAX MANUFACTURING COMPANY

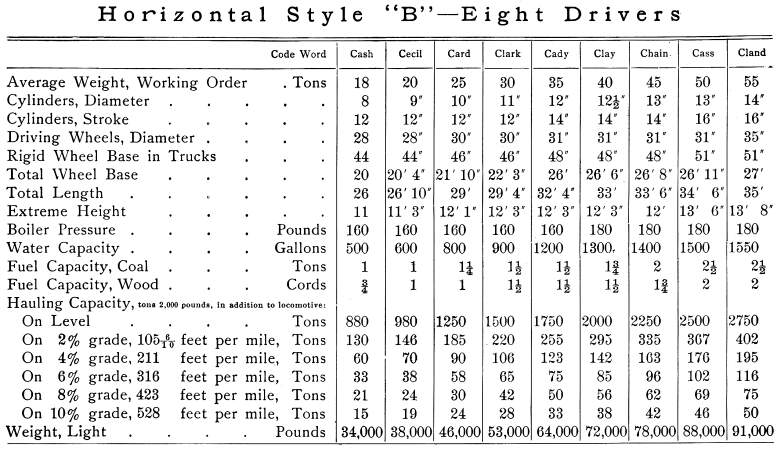

Horizontal Style-Brief Description

THE Climax Patent Geared Locomotive has many points

in its construction peculiar to itself that have earned for it

such worldwide popularity for durability, strength and efficiency.

It is the outcome of a demand for an engine that has great traction

power and flexibility to adjust itself when running upon light

and cheaply constructed tracks, on steep grades, sharp curves

and rough and uneven roadbeds. It is built for any practical gauge,

and to run on either wooden, steel or even pole roads, as desired.

While we recommend the building of steel tracks wherever possible,

yet the wooden stringer railroad is successfully and profitably

operated upon by our locomotive weighing up to twenty tons.

The Locomotive is mounted on two four-wheel trucks which

have a spring over each axle in addition to those between the

bolsters, making them flexible on the road and able to adjust

themselves to irregularities of the track.

A Horizontal Engine is attached to the frame on each

side of the boiler and transmits the power to the square line

shafts, which have universal couplings, extending to both truck

line shafts, on which are steel pinions, meshing into the axle

gears, transmitting the power equally to all wheels and with equal

traction to both rails. The engine parts are all in open view,

readily accessible and adjustable to wear. The cross-heads have

phosphor bronze shoes. The rods have screw wedge adjustment, The

links are made in halves of forged steel, case hardened, and with

the link pins of hardened tool steel with phosphor bronze bushings.

The reversing shaft is made of hammered steel with forged arms,

and the valve motion is perfected by improved link motion, adjustable

to cut-off at equal points and to back up as much as it will pull

forward.

Side

View of Geared Truck

The Boiler is mounted in the center of a steel frame,

and is a regular horizontal locomotive style, having the tubes

well submerged, permitting it to run up the steepest grades without

baring either end. All boilers are tested, stamped and numbered

as required by steam boiler insurance companies. Copper ferrules

are on the fire-box end, preventing expansion and leakage. A water

space is around the firebox, the crown sheet being securely fastened

by stay bolts, screwed down from the top, and riveted at both

ends. There are cleaning out plugs around the corners and a blow-off

cock attached. A large steam dome is in the center, giving dry

steam at all times, from which a dry pipe leads through the smoke

box and saddle to the cylinders. The fire-box is large, giving

plenty of grate service, and grates are provided for coal or wood.

An extension smoke box with spark arresting screen is attached

and suitable cinder dumps and poke holes are arranged so the cinders

can be taken out without interfering with the gearing. A straight

cast stack is used for coal, and a diamond stack, with improved

spark arrester, when wood fuel is used.

The Ash Pan is strongly made, with a proper regulating damper.

Dry steam is taken into the steam box in the cab from which the

connections are made. The boiler is lined with asbestos and covered

with a Russia iron jacket. A sand dome with lever and lead pipes

to the rails are attached.

The Frame is made of steel channels with heavy steel

liners reinforcing the center, large corner brackets being riveted

to the channel and bolted to heavy oak end sills to which the

drawheads are fastened. The frames are connected by double trussed

iron bolsters. Two large truss rods stiffen the frame, having

turn buckles in the center.

End

View of Geared Truck, Showing the Adjustment of Gears

The Trucks, as shown in the engravings, are made on

a new principle. The wheels are all driving wheels. Channels 12

inches wide connect the centers on which the center springs set,

with an additional spring over each axle, making it easy and flexible

on the track. The bolster is double trussed with rub irons on

each end, and a wrought iron tic-bar connects the ends

of the truck frames and supports the brake hangers. A steel gear

is placed on the center of the axle, having the hub pressed to

place, and gear rims made in halves, and are interchangeable,

so that they can be renewed quickly when worn out. The line

shaft runs over the top of the axle and is held in place by our

patented cross-boxes and sleeves. The cross-boxes have interchangeable

phosphor bronze liners made in halves and adjustable to wear.

Sleeve couplings and bronze rings are fitted on the axle between

the gear and the wheel on one side and the cross-box and wheel

on the other, holding the gear in mesh and line shaft in position,

and taking up the side wear. Steel pinions are placed on the outside

of the axle gears next to the cross-box and adjustable collars

are on the line shaft inside the cross-box, preventing the end

play of the shaft and making them adjustable to wear. The power

is transmitted by the line shaft pinions to the axle gears, thereby

giving equal power to each wheel and equal traction on both rails,

and permitting it to curve equally as well one way as the other.

Wheels for wood or steel rails are used as desired.

The axles and line shafts are made of special hammered steel and

are very large to avoid breakage. Journal boxes of approved pattern

are used with heavy brasses, having deep oil cellars filled with

waste.

A Brake Cylinder is attached to the center of the channel

iron on each truck, and the brake lever is connected to the piston

rod of the brake cylinder, making the brake complete on each truck,

swinging with the trucks on curves, and holding the brake shoes

as tightly as on a straight line, without corner binding. By this

arrangement the long brake rod and chain is obviated and double

security is had. The truck frames are made strong and substantial,

and lock nuts are an all bolts, preventing the parts from loosening.

The Cab is of hardwood, with sliding windows and doors

opening onto the running boards on each side of the boiler. An

adjustable ventilator is in center of cab roof. It has wide back

corner ends with window lights, and is fitted with seats for the

engineer and fireman.

The Tank is horse shoe shaped, with flaring top, and

is securely braced and fastened to the frame. The locomotive is

equipped complete with all tools and fittings for its operation,

including steam brake, steam syphon and suction hose for taking

water, two injectors, sight feed lubricator, water gauge try cocks,

steam gauge headlight, bell, whistle, pop valve, machinist hammer,

pipe wrench, monkey wrench, chisel, punch, oil cans, clinker bar

and poker. It is painted, varnished, lettered and numbered as

desired.

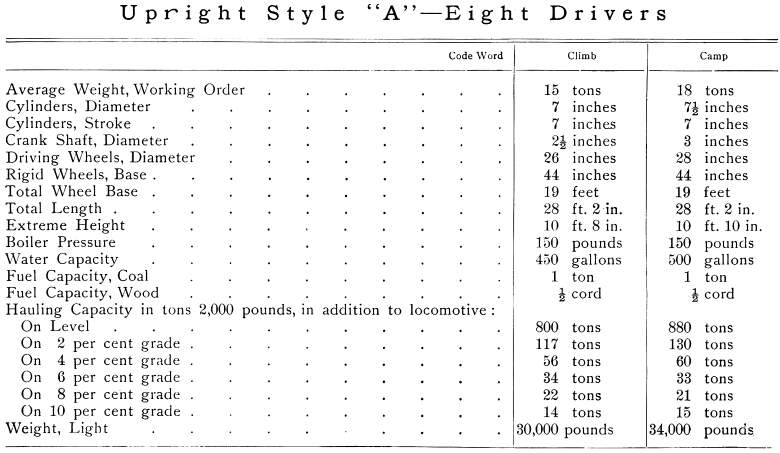

Upright Style—General

Description

WE also build lighter locomotives, having same style

of trucks, with our patent gearing. These locomotives have a frame

made of Southern pine or oak.

A Pair of High Speed Double Acting Engines are located

in the center of the main frame, made of the best material and

workmanship. Phosphor bronze shoes on the cross-heads are adjustable

to wear. Links are made in halves of hardened steel. The main

rods are solid forged, and the brasses are adjustable to wear

by wedge, and all the working parts are made interchangeable as

well as adjusted to wear. A pair of steel spur gears are on the

engine shaft, meshing into a corresponding pair on the center

shaft, which gives two powers or speeds, either of which

may be used, giving the advantage of doubling the power when necessary

to overcome a steep grade, or where an exceptionally heavy pull

is to be made, which is not used on any other geared locomotive

built.

The Center Shaft is made of Steel, on which the main

gears are fitted. Universal couplings and square line shafts connect

to the trucks, permitting each truck to curve independent of the

other.

The Boiler is T shape, having horizontal tubes, a water

space around the firebox, extension smoke box, large steam and

water capacity, and is a very economical steamer. Grates are furnished

for coal or wood.

The Tank is round, carrying plenty of water. The Cab

is canopy shaped, with open sides, and can be arranged for curtain

or enclosed with sliding windows on sides of engine and end doors,

as desired.

It is equipped with all standard fittings and tools for its

operation. We furnish detailed specifications, giving fully all

dimensions of each size locomotive that may be desired with every

proposition that we make.

Double

High Speed Vertical Engine, Used in Upright Style Locomotive

Upright

Locomotive, Style "A"

Horizontal,

Style "B"

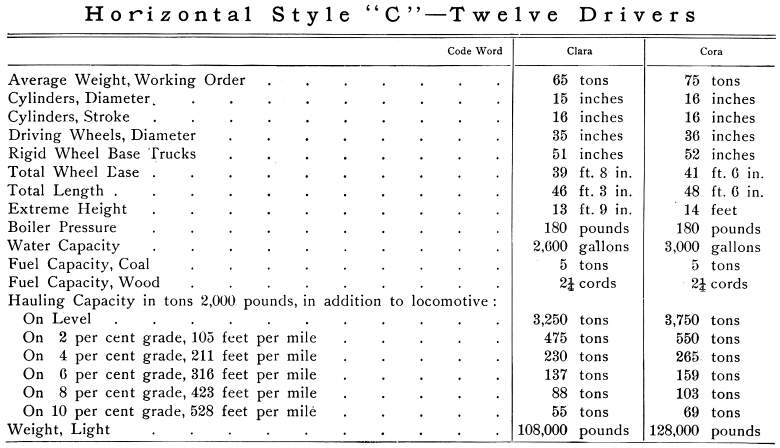

Horiztonal,

Style "C"

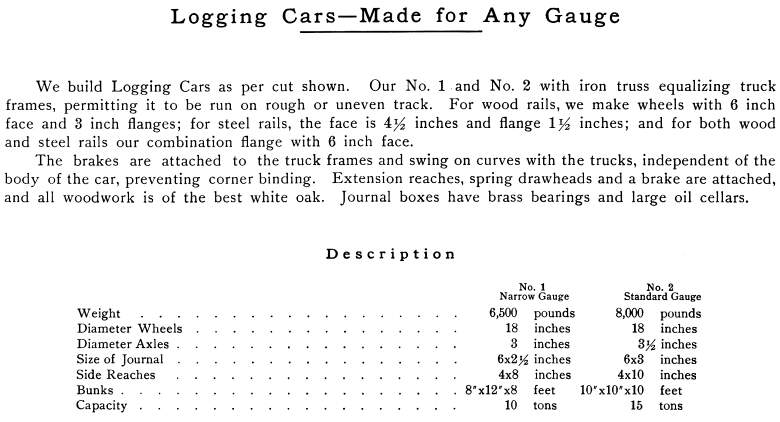

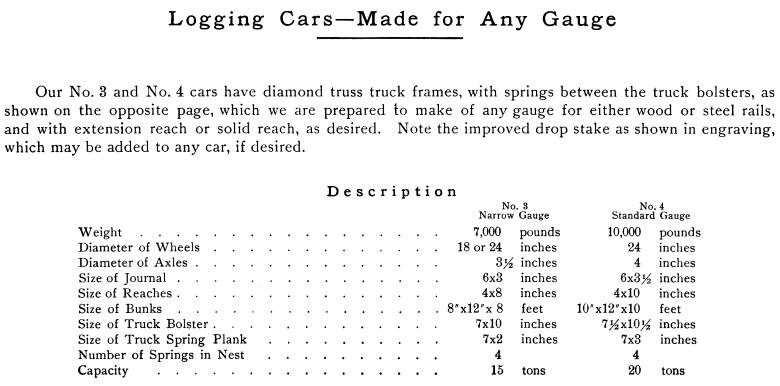

Logging

Car, without Springs

Logging

Car, with Springs

Logging

Car, with Springs

Photograph

1

Photograph

1

Photograph

2

Photograph

3

Photograph

4

Photograph

5

Photograph

6

Photograph

7

Photograph

8

Duplicate Parts

A complete record of each locomotive is kept, as an important

feature of our construction is the system of duplicate parts.

All the working parts of each locomotive are interchangeable with

others of the same class and kind, and blue prints showing all

the working parts numbered and lettered are furnished to every

purchaser.

We keep a stock of fitted duplicate parts for all sizes and

kinds, so that orders for repairs are accurately and promptly

filled.

Special Sizes and Styles

This catalogue contains many sizes and styles of locomotives

from which to select, but we are able to make any change in the

general construction to suit the special requirements of the customer.

We wish the following information in order to submit proposition

and specifications of an engine that we would recommend and warrant

to do the work:

1. Gauge of track and length of road.

2. Steepest grade and sharpest curves on said grade.

3. Weight of load and number of cars to be hauled up the grade.

4. Kind of fuel.

5. Weight of rail.

We will appreciate all the information regarding traffic desired

to haul daily, and number of miles expected to run, as we may

be able to make valuable suggestions regarding the most suitable

engine.

Export Orders

We have been exporting many Locomotives in the past few years

where they come in competition --ith the best European builders,

as well as with our home competitors, but the simplicity of design

of the Climax Geared Locomotive, the ease with which it is cared

for and handled, and the wearing parts kept up and renewed, make

it very easy for the foreigner to run and operate successfully.

The Climax Geared Locomotive is able to overcome the steep grades

and sharp curves over the rough and uneven roadbed, upon light

rails, with greater traction power than other locomotives requiring

much more expensive track.

We have them in Hawaiian Islands, Australia, New Zealand, Mexico

and South America, as well as Alaska, and in nearly every one

of our own States.

Great care is exercised in taking down, boxing and packing

all parts for protection against damages during ocean voyages.

Calculations

1

Calculations

1

Calculations

2

Calculations

3

Logging Page

| Contents Page

|