IMPROVED PORTABLE SAWMILL

Scientific American—November 18, 1876

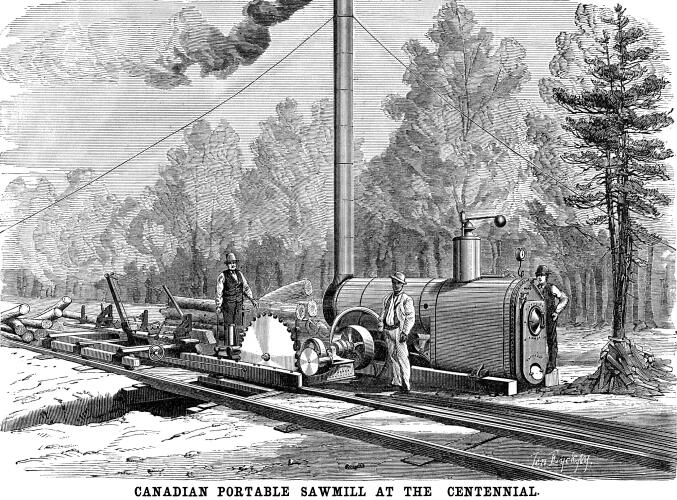

There is on exhibition at the Centennial a machine commonly

known as the Canada sawmill, which has attracted much favorable

notice both on account of the simplicity of its construction and

the speed and accuracy with which it accomplishes its work. It

was designed by the Waterous Engine Company, of Brantford, Ontario,

Canada, expressly for use in the extensive lumber districts of

the Dominion, to saw up the timber in the localities where it

is felled, and thus to save the trouble and the expense of the

carriage or rafting of the logs to distant points; and being portable,

it may readily be moved from an exhausted part of a forest to

a new situation. The machine is also excellently adapted for employment

in shipyards, in most of which establishments in Nova Scotia and

New Brunswick, we are informed, it has superseded whip sawing

by hand.

In the annexed engravings, Fig. 1 represents the mill

as it appeared at work while on exhibition at the Santiago (Chili)

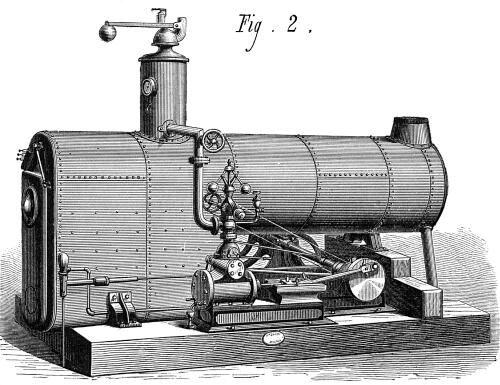

Exposition of 1875; and in Fig. 2 the portable boiler and

engine are shown. The portable machine has a 20 horse power engine,

which, together with its boiler, is of such weight and of such

construction that both boiler and engine may easily be loaded

on trucks, when changing the position of the mill, without any

disconnection being necessary; so that the labor of a skillful

machinist is not required to readjust the mechanism. The saw mandrel,

feed, and gig work are compactly arranged in an iron frame, and

can also be loaded and moved without being taken apart; so that,

when resetting the mill, all that is necessary is to frame the

foundation timbers previously used in the ground, set the mill

on them, coupling the engine shaft and saw mandrel,  lay

the track, place the carriage on it, and the mill is then ready

to start. The whole operation does not take more than from one

to two days. The boiler is supplied with sawdust grates, by means

of which it is enabled to keep up a full supply of steam with

no other fuel than pine sawdust and refuse edgings. It is also

covered with hair felting and lagged with wood or sheet iron.

Its form is clearly shown in Fig. 2. The plates are of

the best English material, and the heads are Lowmoor iron. Each

boiler is subjected to 120 lbs. cold water pressure before shipment.

The 20 horse power engine drives a 56 inch saw, which will, it

is claimed, cut from 6,000 to 10,000 feet of lumber per day, or

1,000 feet of one inch pine lumber in a single hour. The 25 horse

power engine, which is usually employed in connection with a tubular

stationary boiler, drives any size of saw up to 66 inches, and

its capacity is said to be from 8,000 to 12,000 feet of lumber

per day. lay

the track, place the carriage on it, and the mill is then ready

to start. The whole operation does not take more than from one

to two days. The boiler is supplied with sawdust grates, by means

of which it is enabled to keep up a full supply of steam with

no other fuel than pine sawdust and refuse edgings. It is also

covered with hair felting and lagged with wood or sheet iron.

Its form is clearly shown in Fig. 2. The plates are of

the best English material, and the heads are Lowmoor iron. Each

boiler is subjected to 120 lbs. cold water pressure before shipment.

The 20 horse power engine drives a 56 inch saw, which will, it

is claimed, cut from 6,000 to 10,000 feet of lumber per day, or

1,000 feet of one inch pine lumber in a single hour. The 25 horse

power engine, which is usually employed in connection with a tubular

stationary boiler, drives any size of saw up to 66 inches, and

its capacity is said to be from 8,000 to 12,000 feet of lumber

per day.

At the Chili Exposition, the 20 horse power mill, we are informed,

sawed and edged 1,060 feet of lumber in 40 minutes, vanquishing

all competitors and gaining a medal and diploma. It has received

the first premiums at ten Canadian Provincial Exhibitions, besides

a highly favorable report from the judges at the Centennial.

Logging Page

| Contents Page

|