|

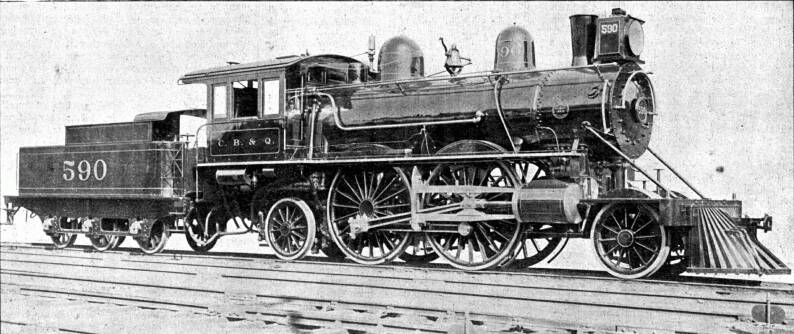

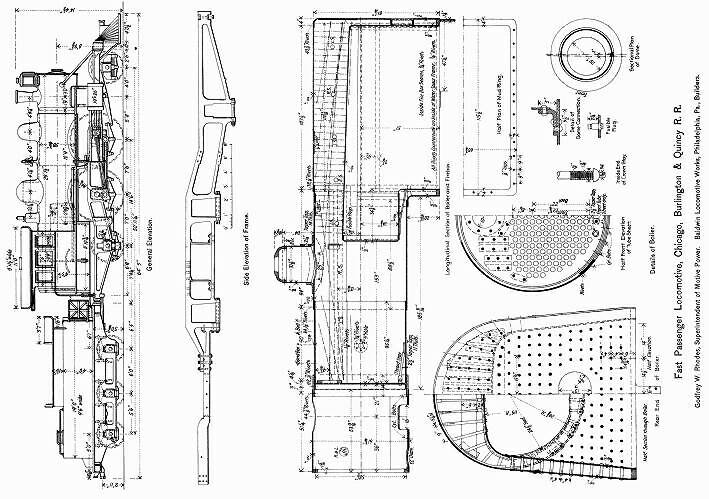

EXPRESS LOCOMOTIVE FOR THE CHICAGO, BURLINGTON & QUINCEY

R.R.

Engineering News—Dec., 1895

One of the notable departures from the ordinary types of express

engines is that known as, the "Columbia" type, which

has four driving wheels (of which the rear pair are the main drivers),

a two-wheel, or pony, leading truck, and a single, pair of trailing

wheels, which have 4-in. extra

play. This type of engine was first designed in 1891 by the Baldwin

Locomotive Works to meet the special requirements of the Philadelphia

& Reading R. R., as shown in our issue of Nov. 21, 1891. These

engines had the Wootten type of firebox, and one of them, illustrated

in our issue of June 15, 1893, was exhibited at the Columbian

Exhibition. All of these engines were Vauclain four-cylinder compounds,

and have given most excellent results in service. There was also

exhibited at the Columbian Exhibition a locomotive of similar

type, but with a narrower firebox, designed to burn bituminous

coal, and this engine, which attracted much attention, was named

the "Columbia," from which the name of this type of

engine has been derived. This engine has, since the close of the

exhibition, been run on several different roads, and has given

very excellent results.

A similar engine to the "Columbia," but single, expansion

instead of compound, has recently been built for the Chicago,

Burliugton & Quincy R. R. by order of Mr. O. W. Rhodes, Superintendent

of Motive Power. This engine is shown on our inset sheet this

week, and we are indebted to the Baldwin Locomotive Works for

drawings and specifications from which this article is prepared.

The engine has a very handsome appearance, and among its -striking

features may be noted the arrangement of wheels on both engine

and tender and the use of piston-valves on a simple engine, while

the size of the driving wheels—7 ft.—is unusual for

Western roads. The general dimensions and particulars of the engine

are as follows:

The frames are of steel, and are dropped at the rear end to carry

a deep firebox over the small trailing wheels. The boiler is made

of 11-16-in. steel flange plates, having all the longitudinal

seams butt jointed, with double covering strips calked inside

and outside. The throat sheet is 8

in. thicker than shell plates, to prevent undue thinning where

it is flanged. The waist is 58w

ins. diameter at the smokebox end, with a straight top, and having

a dome ring of pressed steel 1 in, thick. The firebox is of steel,

and has a combustion chamber 3 ft. long, in which is a firebrick

arch. The 18-in. radial stays

of the crown are screwed through the crown sheet and riveted over,

and all solid staybolts and stays have drilled ends. The firebox

is designed for burning soft coal, and has a grate of the rocking

and drop pattern, while the ashpan has front damper slides in

the bottom. The tubes are of iron, No. 11 B. W. G., with copper

ferules on the swaged ends in the firebox tube sheet. The smokebox

has an extension front, with wire netting, deflecting plate and

spark hopper, and a, straight smokestack is used. The feed is

supplied by two Sellers injectors. The cylinders are lagged with

wood and eased with iron, and the cylinder-head covers are of

hydraulic forged steel, polished and filled with asbestos. The

boiler is lagged with asbestos cement, and jacketed with cold-rolled

pickled steel (painted), with steel bands. The fittings include

two Richardson sealed safety valves, the teach sanding apparatus

and the West bellringer. The Jerome metallic packing is used on

piston-rods and valve stems.

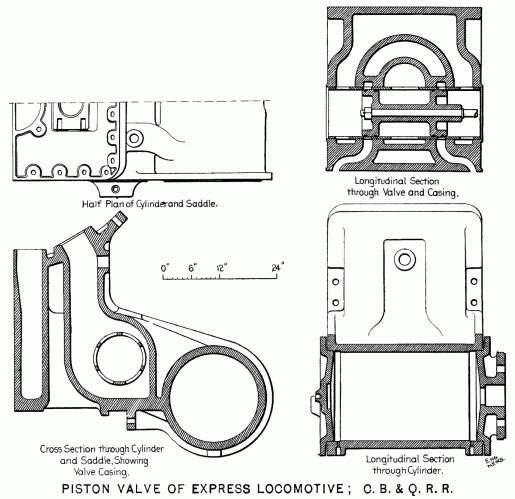

The cylinders have piston slide valves fitted in the saddles,

as shown, an arrangement which is rather novel in simple engines,

although it has been tried recently in England, and the design

is very similar to that used in the Baldwin four-cylinder compound

engines. It will be seen by the list of dimensions that these

valves give a great port area. The pistons are of cast iron, with

piston rods of open-hearth steel fitted to the cast steel crossheads,

which have brass bearings. The cylinders and air pump are lubricated

by Nathan automatic sight-feed lubricators placed in the cab.

The connecting and side rods are of open-hearth steel, all of

I-section, and the side rods have solid ends with heavy

brass bushings put in by hydraulic pressure. The driving-boxes

are of steeled cast iron, with brass, bearings.

The wheels have cast steel centers, those of the driving, wheels

being 6 ft. 6 ins. diameter, and the tires are secured by shrinkage

and retaining rings. The driving-wheel tires are of cast steel,

38ins. thick and 52

ins. wide, both pairs being flanged. The Westinghouse-American

outside equalized brake is fitted to the driving, trailing and

tender wheels, and is operated in connection with the Westinghouse

train brake, a 92-in. brake-pump

being used. The train air-signal is also fitted.

A special feature of this engine is the six-wheel tender, with

plate frames, this having been adopted by the C., B. & Q.

R. R. as an experiment to ascertain whether there is any advantage

in European practice in this respect. The three-cylinder mogul

engines of the Erie & Wyoming Valley R. R. (Eng. News, Feb.

7, 1895), as well as, one or two of the Pennsylvania R. R. express

engines, have six-wheel tenders. On the other hand, some of the

English papers and engineers are advocating the use of the American

tender on two four-wheel trucks for the heavy express engines

hauling heavy trains long distances.

This tender has a tank of 4,000 gallons capacity, with

4 plates for top, inside and

bottom, and 3-16-in. plates for the outside, put together with

7-16-in. rivets. The tank is of U or horseshoe shape, with

an inclined floor for the coal space, and rests upon a steel frame.

The wheels have wrought iron centers and steel tires, and the

axles have outside journals, the boxes working in pedestals. A

railing extends beyond the tank to protect the footplate, and

there is a cab over the tender deck.

Contents Page | Build a Locomotive

|