|

THE ST. GOTHARD TUNNEL. THE ST. GOTHARD TUNNEL.

Harper's—Vol. LVII—No. 341—42

ca. 1878

FEW Americans visiting the World's Fair at Paris this year

will fail to examine a magnificent map or panorama they will see

there of the Great St. Gothard Tunnel. It is in the Swiss Department,

and is not only interesting as locating the route of the greatest

piece of engineering in the world, but as showing bits of the

most picturesque scenery of the Alps.

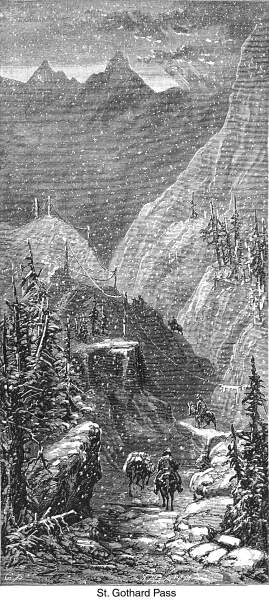

To go under the Gothard Pass, as I had gone over it, had long

been a desire of my heart, but there had always been difficulties

in the way.

"It is a dirty, dangerous job," said a friend of

mine recently, when I told him I was going up into the mountains

in winter—and more, that I was going right under them and

into the great tunnel. "You'll not do it," he continued,

laughing and shrugging his shoulders—"I know you won't.

And I'll tell you why. In the first place, the awful gases in

there would suffocate you, the rivers of water would drown you,

and the explosions of dynamite would blow you up. Again, you would

back out before going in a mile; and lastly, you couldn't get

permission to go in at all."

I knew there was dynamite there, and bad gases and rivers of

water, but I reasoned that what several thousands of Italian workmen

could live amid for months I certainly could endure for a few

hours.

As to permission, I had that in my pocket—a little red

ticket, printed in French, and saying, "Pass Mr. B—and

two friends into the tunnel at Goeschenen." I had, besides,

a letter of introduction from the chief engineer to the principal

officer in charge, as well as some good recommendations from Engineer

Lauber, the affable and competent secretary at head-quarters.

It was midwinter, and the snow on the Alps lay all the way from

ten inches to twenty feet deep. Our route took us by rail from

Zurich to Lucerne, and a three hours' steamboat ride through the

wonderful scenery of the Lake of the Forest Cantons brought us

to Fluelen, the real gateway to the St. Gothard Pass, and a district

rich with memories of William Tell. Sledges carried us four hours

up the pass, and before the sun could peep over the broad shoulders

of the Bristenstock we were in the offices of the company at Goeschenen.

My letters and my pass were presented, and, after dinner, I

was to be allowed an inspection of the great tunnel.

Before entering into any description of it, however, and the

methods by which it is being built, it might not, perhaps, be

amiss, just here, to recall in a few words something of the history

of this vast undertaking.

There are men living to-day in Switzerland and Italy whose

life-dream has been a tunnel under the Alps. Many schemes have

been investigated, and many schemes have failed.

These mighty barriers of mountains have for ages divided peoples

that but for them might have been of one language, one interest,

alike in laws and customs. For five hundred years there was but

a stony path across the Helvetic Alps, where the St. Gothard post-road

was afterward built; and it is but a century since the first vehicle

on wheels was dragged over the pass, at an expense of several

hundred dollars. Till that time, the traffic between two nations

was borne on the backs of mules and men, who struggled, at the

risk of death, along narrow stony ways, winding around glaciers,

high mountain peaks, and yawning gulfs: 16,000 persons and 9000

horses climbed over these dizzy heights annually.

There were scarcely fewer dangers to be encountered by the

bold trader even forty or fifty years ago—sudden storms,

almost eternal snows, avalanches, falling rocks, dangerous and

unbridged torrents, and even robbers. Nature and man conspired

to make the path of the St. Gothard one of awful risk and dangers.

It winds among granite pyramids and peaks nine to ten thousand

feet in height, and the road itself reaches an elevation of nearly

seven thousand feet. Even now the snows on the pass are so deep

and the dangers are so great that commerce and travel over the

St. Gothard cease for half the year entirely, the mails being

carried over by messengers. Such are a part only of the disadvantages

arising to some sixty or seventy millions of people from this

mighty mountain wall between Switzerland and Italy.

The building of the Mont Cenis Tunnel through the Savoy Alps

to France, and the Brenner Road to Austria, have made it absolutely

necessary for Germany and Switzerland to choose between losing

the commerce and travel of the South, and building a mountain

railroad, and a series of tunnels that shall eclipse any thing

of the kind in the world. The world knows how they have chosen.

The enterprise was too enormous for private undertaking or

for private capital. In 1871, Italy, Germany, and Switzerland

voted large subventions for the building of a road, to be commenced

at once, running from the Lake of Lucerne, in Switzerland, to

Lake Maggiore, in Italy, a distance of 108 miles. Twenty-one per

cent., or nearly 120,000 feet, of all this distance, was to be

tunnelled through mountains of granite.

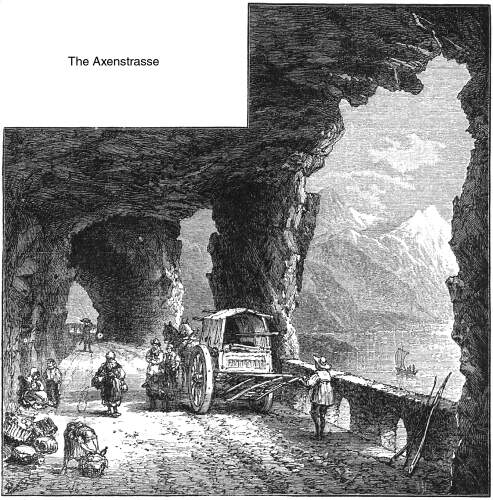

The total length of the main tunnel, which enters the Alps

at Goeschenen, in Switzerland, and emerges at Airolo, in Italy,

is 48,936 feet. A number of the smaller tunnels, bringing the

road up to the proper level in the Alps, exceed 7000 feet. On

the Lake of Lucerne, too, there will be important tunnels and

galleries cut alongside of or under the celebrated Axenstrasse,

high above the waters of the lake.

At the time the international treaty for this great undertaking

was signed it was believed that the -work could be done for the

sum of 187,000,000 francs. A company was organized, with 34,000,000

francs of stock, in £20 shares, and 68,000,000 francs of

mortgage bonds. Italy presented the undertaking with 45,000,000

francs. Germany and Switzerland each gave 20,000,000 francs. The

work, however, was not more than fairly under way when it was

discovered, to the astonishment of every body, that an awful mistake

had been made in estimating the costs, and that, instead of 187,000,000

francs, 289,000,000 would be required to complete the work as

at first proposed—a blunder in estimates of 102,000,000 francs.

This blundering calculation threatened all sorts of bad results.

The stock of the company ran down to a minimum, and hundreds of

families were nearly ruined by the collapse. The bonds shared

in the crash, and even the most ardent friends of the enterprise

feared that the money which had been so lavishly given was buried

under the mountains forever. It became a serious question whether

the works would not have to be completely abandoned. There certainly

was no choice, except to lose all that had been done, or to add

many millions more to the subventions. The times were hard, financial

crises were imminent every where, and war was raging on the Continent.

Every body was discouraged. Some of the little cantons of Switzerland,

which would receive the most benefit from the completion of the

tunnel, refused to lift a hand or to spend another dollar.

In the face of all opposition, however, the money has, at this

writing, been almost raised. The three countries, parties to the

treaty, have added largely to their subsidies, and the leading

Swiss railways and cities have each voted sums proportioned to

the advantages they hope to reap. The work goes on—in fact,

has never stopped.

The contract

for this enormous work is most interesting. It was granted to

Mr. Louis Favre, of Geneva. By its terms Mr. Favre promises to

deliver the works of the tunnel, completed, by the 1st of October,

1880. For each day the work may be done before that time the company

agrees to pay him $1000. On the other hand, however, the contractor

is bound to pay handsomely for all delays. For every single day

in arrear of contract he forfeits $1000. If delay continue six

months, the forfeit is $2000 per day; and should be one year in

arrear with his work, he surrenders the contract, and forfeits

$1,600,000, which he, and his friends for him, have deposited

with the company as security. The contract

for this enormous work is most interesting. It was granted to

Mr. Louis Favre, of Geneva. By its terms Mr. Favre promises to

deliver the works of the tunnel, completed, by the 1st of October,

1880. For each day the work may be done before that time the company

agrees to pay him $1000. On the other hand, however, the contractor

is bound to pay handsomely for all delays. For every single day

in arrear of contract he forfeits $1000. If delay continue six

months, the forfeit is $2000 per day; and should be one year in

arrear with his work, he surrenders the contract, and forfeits

$1,600,000, which he, and his friends for him, have deposited

with the company as security.

On January 1, 1877, the headings, or a sort of advanced

gallery eight feet square pushed forward at the top of the tunnel,

were half-way in. Whether the gigantic work can really be completed

within the time specified is a grave question for Mr. Favre. Opinions

differ, and even engineers can do little more than guess.

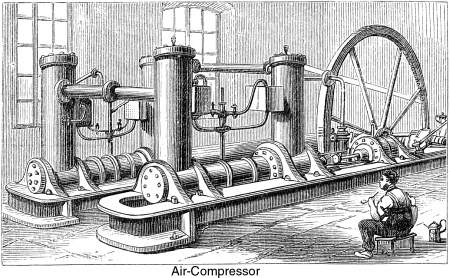

After dinner Mr. Zollinger, the second engineer at the works

in Goeschenen, kindly called and invited our party to examine

the great air-compressors and machine-shops outside the entrance

of the tunnel, The machines with which the granite is being bored

are working away, several miles off, under, the heights of Monte

Prosa. The power moving these machines is quietly lying out here

on the hillside, locked up in four great iron boilers, or reservoirs.

It is compressed air. These boilers are connected with the machines

working inside the tunnel, and bear the same relation to them

that the steam-boiler does to the engine. Steam could not be conducted

through pipes for miles, as it would cool and condense; neither

could shafting nor belts be made to act at such immense distances.

With air, however, the thing becomes easy and perfectly simpler

The improved air-compressors which supply this force stand in

rows in a long low building near the tunnel. They are simply vast

air-pumps, compressing the air to a density of from seven to twelve

atmospheres.

As I am not writing for engineers alone, I will not attempt

to describe these immense machines in all their details, but will

content myself with saying that their application, or rather the

application of compressed air to this purpose, is not new, as

air-engines and boring-machines, though of a far inferior construction,

were used in driving the Hoosac Tunnel in America, the Mont Cenis

in Savoy, and at other different works of this character. They

may be operated either by steam or by water power.

Those at Goeschenen are actuated by ten Girard turbines, which

are driven, by a heavy stream of water, conducted from a point

more than 2000 feet along the mountain and 200 feet higher up,

where the river Reuss fortunately dashes by. The water is first

filtered in an immense basin of masonry, in order that the compressors

may not be injured by sand, etc., and is then carried down to

the compressing-house by iron tubes thirty-three inches in diameter.

This force of water, dashing through the turbines, enables

the compressors now in operation to deliver into the reservoirs

outside 3,620,000 cubic feet of air per day, equalling some 25,000

cubic feet, compressed to six atmospheres, per hour.

This compressed air passes from the reservoirs to the machines

in the tunnel through an iron tube six inches in diameter, and

serves not only to drive the drills, but to ventilate the tunnel.

Of course, as the air escapes from the drill engines inside, its

tendency is to force the gases and smoke backward, and at last

out of the tunnel. These gases and smoke are produced in part

from natural causes, but largely from dynamite explosions, as

well as from the burning of thousands of lamps, and the respiration

of the workmen.

An idea may be had of the condition of the atmosphere inside

the tunnel if it be remembered that not less than 210,000 cubic

feet of this gas and dense smoke have to be forced out of the

tunnel daily. The compressed air escaping from the boring-engines

at the head of the tunnel, however, is supposed to be more than

sufficient for this task of expulsion, as its bulk averages at

both ends about 7,000,000 cubic feet per day.

Still, the escaping air, powerful as it is, must combat the

column of air already filling the tunnel for several miles back.

The result is that the ventilation of the tunnel is, and always

will be during the blastings, very incomplete.

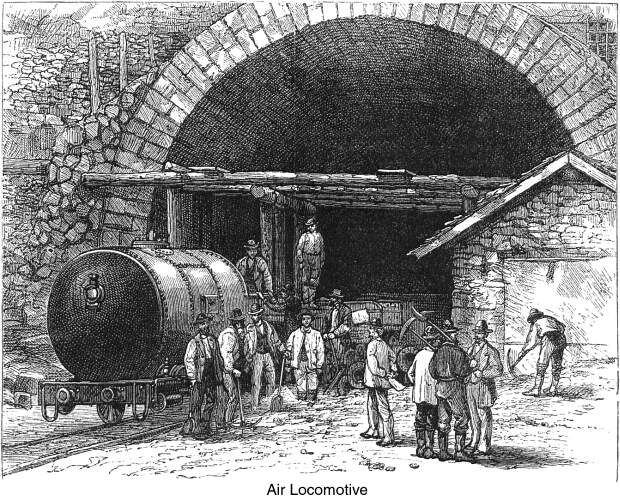

Before entering

the tunnel it is worth while to consider the strange-looking locomotives

which serve for pulling in trains laden with rock, mortar, iron,

etc., and for pulling out trains laden with the debris of the

tunnel: 400 car-loads of debris are taken out of the two ends

of the tunnel daily. Of course such a circulation of steam locomotives

with steam and smoke and ashes escaping, would be unendurable

in a long and half-ventilated hole in the ground. Something had

to be done; other means had to be sought for, and Mr. Favre concluded

to try air locomotives. He first experimented with small engines

and very low pressures, and finding them a success, he has introduced

large engines, working with a pressure of from twelve to fifteen

atmospheres. To compress air to this extent, special compressors

were built and new reservoirs added. Before entering

the tunnel it is worth while to consider the strange-looking locomotives

which serve for pulling in trains laden with rock, mortar, iron,

etc., and for pulling out trains laden with the debris of the

tunnel: 400 car-loads of debris are taken out of the two ends

of the tunnel daily. Of course such a circulation of steam locomotives

with steam and smoke and ashes escaping, would be unendurable

in a long and half-ventilated hole in the ground. Something had

to be done; other means had to be sought for, and Mr. Favre concluded

to try air locomotives. He first experimented with small engines

and very low pressures, and finding them a success, he has introduced

large engines, working with a pressure of from twelve to fifteen

atmospheres. To compress air to this extent, special compressors

were built and new reservoirs added.

The appearance of these air locomotives is that of an immense

tube or cylinder lying on low wheels. They are made of steel,

and the engine part does not differ materially from that of any

ordinary locomotive. It is only that air and not steam is used

as a motor.

Should these travelling air reservoirs become exhausted at

any time on the trip into the tunnel, additional air may be turned

on through cocks and rubber pipes from a special air tube which

is laid for this purpose.

The development of this principle of an air locomotive will

doubtless yet settle the vexed question of the ventilation of

long tunnels.

When our intelligent cicerone, Mr. Zollinger, had shown us

the air-compressors, the turbines, the repair shops, and trip-hammers

worked by compressed air outside the tunnel, he transferred us

to the attentions of his deputy, Mr. Isaac, who promised to show

us inside the tunnel, or what, he laughingly termed "a glimpse

at the bowels of hell."

We had worn pretty good clothes from Zurich, and had adorned

ourselves with collars and cuffs of immaculate whiteness that

very morning.

"Es macht nichts," said our lively conductor;

"a white cuff can't hurt a coal mine."

We were invited to strip off, in part, and in a few minutes

we were arrayed in sole leather boots reaching to the thighs,

little pea-jackets lined inside with petroleum and outside with

mud, and old slouch hats heavy and soiled enough to have been

bullet-proof. We were then each given all antique-looking petroleum

lamp, with rod attached, to carry in the hand.

"Now jump right up here beside me on the locomotive,"

said our friend, "and you need not light your lamps until

you are in, as the current of air from the moving train would

extinguish them."

Four of us

with the engineer stood on the little cow-catcher platform at

the front end of the engine, and were soon hurled off into the

darkness. The screaming of the engine whistle right at our ears

was frightful, and the darkness was so utter and the smoke so

thick we fancied we could feel them with our hands. The gases

began to be almost unbearable, and the miscellaneous noises throughout

the tunnel something terrific. Four of us

with the engineer stood on the little cow-catcher platform at

the front end of the engine, and were soon hurled off into the

darkness. The screaming of the engine whistle right at our ears

was frightful, and the darkness was so utter and the smoke so

thick we fancied we could feel them with our hands. The gases

began to be almost unbearable, and the miscellaneous noises throughout

the tunnel something terrific.

I presume our train was not running fast, and yet it made so

much noise, and the surroundings were so unusual, it seemed as

if I had never in my life bounded along at such a rate. I had

had many a strange ride, too, before, but never had I felt so

completely helpless, or more likely to be snuffed out by the unseen

should any thing happen to the rails, or to the novel machine

on which we were riding. As we rushed by dripping walls, and saw

here and there ghoul-like figures with dim lamps hiding behind

rocks or, in deep niches, I involuntarily recalled what our conductor

had said of a glimpse of the bowels of hell.

It was impossible to speak and be heard, I might as well have

addressed myself to the granite walls of the tunnel as to have

attempted a word to either of my companions. Suddenly our locomotive

gave one extra, unearthly yell, and stopped. We alighted, got

our lamps burning, and with a little motion on our own feet soon

felt ourselves again. The engine sped back, screaming and rattling

like the voices of Milton's damned.

We now started forward in the tunnel on foot, and, as we recovered

our breath, had abundant time to look about, though there seemed

something fatally wrong with the perspective of the picture of

which we formed a part.

The air was so thick lights could not be seen twenty yards

ahead of us, and we all walked close together for fear of being

lost or tumbling into some subterranean hole.

Far ahead of us we heard the dynamite explosions, sounding

like heavy mortars in the midst of battle. In some places where

we were, walking the water was nearly a foot deep, and again it

came through crevasses above our heads like April showers. Our

conductor tells us that on the Airolo side of the tunnel the waters

have sometimes come in at the rate of 4000 gallons per minute,

and in such torrents as to even upset the workmen and carry away

the tools. Again, an occasional spring would burst out in a stream

as thick as a man's arm, while the track for the drills was frequently

laid in rushing water two feet deep. This water comes from springs

in the mountains about us, and from eternal snow-fields lying

in the sunshine thousands of feet above our heads.

It is very

impressive to reflect that, as we stand here in the dim light

of the tunnel, far above us are lofty mountains and fields of

snow, tumbling avalanches and roaring torrents. Almost above us

are the peaks of the St. Gothard, reaching above the clouds; and

there, too, is the rapid, roaring river Reuss, with its leaping

waterfalls, and the Devil's Bridge, where French and Austrian

soldiers met in deadly conflict. Up there, too, are the bright

sunshine and the cold snow of the winter, and the diligences and

sledges filled with freezing passengers, while we are melting

under 80 degrees Fahrenheit of heat, and the Italian workmen are

almost naked. There, too, above our heads, in the glistening glaciers,

are the first rippling of the baby Rhine. Behind us are the cold

hills of Switzerland. In front of us, and just outside those granite

rocks, is sunny Italy. How strangely we feel! It is very

impressive to reflect that, as we stand here in the dim light

of the tunnel, far above us are lofty mountains and fields of

snow, tumbling avalanches and roaring torrents. Almost above us

are the peaks of the St. Gothard, reaching above the clouds; and

there, too, is the rapid, roaring river Reuss, with its leaping

waterfalls, and the Devil's Bridge, where French and Austrian

soldiers met in deadly conflict. Up there, too, are the bright

sunshine and the cold snow of the winter, and the diligences and

sledges filled with freezing passengers, while we are melting

under 80 degrees Fahrenheit of heat, and the Italian workmen are

almost naked. There, too, above our heads, in the glistening glaciers,

are the first rippling of the baby Rhine. Behind us are the cold

hills of Switzerland. In front of us, and just outside those granite

rocks, is sunny Italy. How strangely we feel!

Our conductor stops us to name the strata of rock through which

we are walking. The first 7000 feet at the Goeschenen end had

been through dark gray granite or granitic gneiss; then followed

1000 feet of schistous gneiss, lying in vertical ledges; then

500 feet of crystalline limestone, with here and there a streak

of black serpentine, followed by 3000 feet of micaceous schists,

and some 20,000 feet of gneiss rich in mica. This is followed

again by 5000 feet of schistous gneiss, with threads and lumps

of quartz, and nearly 10,000 feet of mica schist, ending on the

Italian side with some 2000 feet more of mica schist mixed with

gneiss and rich veins of quartz. Such were the calculations made

by the geologists from the mountains above the tunnel, and the

boring so far has proved these observations to have been pretty

nearly correct. But little gold, silver, or other precious ore

has been met with, and even stone-coal has failed to put in an

appearance, much as it would be welcomed by the Swiss, who have

scarcely a pound of coal in their whole Alpine country.

The tunnel has about the same dimensions, except in length,

as the Mont Cenis Tunnel; that is, it is, in round numbers, twenty-four

feet in width at sleepers, twenty-six feet wide at springing of

arch, and nineteen feet high between sleepers and centre of arch.

It starts into the mountain at a point 3639 feet above the sea,

and comes out at Airolo, on the Italian side, 3757 feet

above the sea-level.

On the north axis the tunnel ascends one foot in every 172

feet, or about 142 feet in traversing the distance of 24,462 feet.

It then follows a summit or level line for the next 591 feet,

when it descends to Airolo, 24,279 feet farther, at a gradient

of one in 1000. The highest point in the tunnel, hence, is 142

feet above the entrance at the north end, and, twenty-four feet

only above the outlet at the south. These gradients are for the

purpose of permitting the water to pass off through a channel

of masonry cut between the two tracks of rails toward either end.

Almost the entire tunnel is being arched and lined with solid

masonry, eighteen to thirty inches in thickness, and that, too,

in places where the granite and serpentine blocks seem to the

ordinary observer the perfection of solidity.

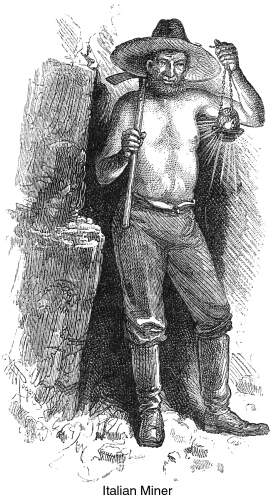

As we advance

farther we come upon hundreds of men working in groups, drilling

and blasting rock, loading cars, and building up the masonry.

The tunnel here, seems better ventilated, and the lights moving

about every where look strange enough. The workmen are all Italians.

No other workmen, says our conductor, will accept so much toil

and danger for so little pay. The Swiss and Germans will not,

and the French will not, so the illy fed Italian has it all to

himself. Like John Chinaman, he can live on little and work cheaply.

It has never occurred to the rest of the working classes in Switzerland,

however, that they should adopt the California method, and drive

off or murder the Italian Chinaman on account of his cheap labor. As we advance

farther we come upon hundreds of men working in groups, drilling

and blasting rock, loading cars, and building up the masonry.

The tunnel here, seems better ventilated, and the lights moving

about every where look strange enough. The workmen are all Italians.

No other workmen, says our conductor, will accept so much toil

and danger for so little pay. The Swiss and Germans will not,

and the French will not, so the illy fed Italian has it all to

himself. Like John Chinaman, he can live on little and work cheaply.

It has never occurred to the rest of the working classes in Switzerland,

however, that they should adopt the California method, and drive

off or murder the Italian Chinaman on account of his cheap labor.

These Italians work eight hours, and they receive from three

to six francs a day, boarding themselves. Of course it is a small

percentage of them who receive the maximum. wages; and yet, strange

as it may seem, they save more than one-half the money paid them,

and send it to their needy families in the dominions of King Humbert.

Their food is extremely limited in quantity, and is wretched in

quality, consisting largely of polenta, or a sort of Indian meal

porridge. Meat they never taste at all. They are contented to

receive their forty or fifty cents a day for hard work, if they

can only escape wounds and death from the bad gases and the thousand

accidents to which they are liable every moment of their lives

in the tunnel. Alas! they do not escape, for every week records

its disaster, either from explosions and flying rocks, falling

timbers and masonry, or railway accidents, breaking machinery,

etc. They have their "striking" troubles, too, with

fatal endings. Our conductor grew excited when he related the

story of one of these striking episodes.

"I was standing right here," he said, "in a

niche in the wall, superintending some work, when I heard, all

of a sudden, a tremendous shouting of many voices. I looked ahead

of me into the darkness of the tunnel, and saw perhaps a thousand

lights rapidly approaching and I heard the words, 'The mine! the

mine! Run for your lives! Gas! gas! Run!' In a minute thousands

of half-naked workmen were rushing by we like a herd of mad buffalo.

Some hold handkerchiefs to their months, some their hands only,

or bits of garments. They were running over each other, and their

hallooing was perfectly terrific. I shouted at them to learn what

was wrong. No man stopped. I could only distinguish the words,

'The mine! the mine! Run for your lives!' I jumped from the niche

where I was standing, and ran—ran for my life—for I

now feared some awful explosion had taken place, or that an under-ground

stream had been struck, and that the tunnel was filling with water.

I thought, too, I felt the deadly gases being rapidly pushed after

me. How I ran! My side still aches from that awful race to reach

the mouth of the tunnel. I saw daylight, but, death or no death,

I could go no farther. I sat down at the side of the tunnel, a

badly used up man. After resting and getting forward, I saw the

whole herd of workmen that had rushed by me standing about the

company's buildings, gesticulating and loudly talking. There had

been no explosion, no water breaks, no danger, no nothing. It

was simply a strike—I think not so much for better wages

as for better air—and they had adopted this method to scare

every body out of the tunnel. So far it was a great success. The

mob still held the road, and effectually interfered with all further

progress of the work. Then the Tessin soldiers came, and, justly

or not, fired on them, and numbers of the poor fellows were killed

or wounded. It was the only strike at the tunnel. I hope sincerely

it will be the last."

These Italians look strange enough, moving about with their

dim lights, broad hats, black faces, high boots, and with bodies

naked to the waist.

Cold and wintry as it is among the glaciers and avalanches

above our heads, it is warm enough in here. The ordinary temperature

of the tunnel is about 65 degrees Fahrenheit, and after an explosion

the mercury jumps up to 86 degrees. The most tremendous perspiration

overcomes one, even when standing still, and the men at the drills

could not be wetter were they just taken from the bath.

The explosive material used is dynamite almost exclusively,

and its force is of a character to make gunpowder seem a mild

agent in its presence. It is used in preference to nitroglycerine,

because it is somewhat cheaper and very much safer. As to its

strength, I saw places where the concussion following the explosions

after drilling had broken granite blocks three feet in thickness

in twain, and had driven the solid key-stone of the masonry in

the arch up into the mountain. At one point, outside the tunnel,

where dynamite cartridges had been stored, an accidental explosion

blew a number of workmen so completely into atoms that nothing

of them, save their heavy boots containing their mangled feet,

was ever found. A discharged workman one night threw a single

cartridge of this dreadful compound into one of the offices of

the company, resulting in as complete a tearing to pieces as could

have followed had the rooms been match-boxes. The officers fortunately

were all absent from their accustomed places.

There are about fifty air-drills at work in each end of the

tunnel, and these are operated against the rock at some seven

different points of attack; that is, at the forward end of the

main heading, and at points right and left farther back, as well

as on banks of rock that have been left behind while pushing the

head gallery forward. Some of the machines, too, have been turned

around at these sidings, and are worked backward against the still

standing rock.

The main heading is worked on what is known as the Belgian

system, viz., boring a hole in advance, about eight feet square,

where the top of the tunnel is to be. Often, too, when only the

upper half of the tunnel has been drilled out, the arch is put

in and finished, the base or sides being built after the lower

half of the tunnel has been excavated. This is done by bracing

the arch or roof up with heavy timbers until the rock at the bottom

of the tunnel is removed, when the side walls on which the arch

is to rest are laid up, and the timber supports knocked out. This

complete arch is usually put in in sections of about eighteen

feet, and after having been allowed a few days to settle, other

sections are joined on.

There are few of the uninitiated who have not wondered to themselves

how the arch to a railway tunnel is put in.

If the tunnel

be through hard rock, the arching is simple enough. A square hole

is driven in three or four feet wider and higher than the tunnel

will be when completed. Great wooden or iron bows or ribs, the

shape of the proposed arch, are then set in at short distances.

Over these half-circular ribs are laid timbers, reaching from

rib to rib, and running parallel with the tunnel. This forms,

then, a wooden arch open at the top. On this arch the masonry

is laid, additional timbers being placed on the ribs toward the

key-stone, or top, as the stone-work is built up. The open space

between the masonry and the earth is filled in as best it may

be with stones and wood to prevent the earth's sinking too suddenly

on the arch. The work is especially simple and easy when the arch

is put in in short sections. When the last wedge or key-stone

is placed, the supporting ribs and timber are pulled away, and

the stone arch stands complete. If the tunnel

be through hard rock, the arching is simple enough. A square hole

is driven in three or four feet wider and higher than the tunnel

will be when completed. Great wooden or iron bows or ribs, the

shape of the proposed arch, are then set in at short distances.

Over these half-circular ribs are laid timbers, reaching from

rib to rib, and running parallel with the tunnel. This forms,

then, a wooden arch open at the top. On this arch the masonry

is laid, additional timbers being placed on the ribs toward the

key-stone, or top, as the stone-work is built up. The open space

between the masonry and the earth is filled in as best it may

be with stones and wood to prevent the earth's sinking too suddenly

on the arch. The work is especially simple and easy when the arch

is put in in short sections. When the last wedge or key-stone

is placed, the supporting ribs and timber are pulled away, and

the stone arch stands complete.

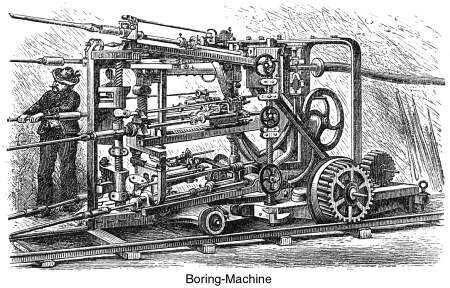

But to return to the tunnel. If we push forward from where

we are, we will soon have a good view of an air boring-machine

at work. It may be described as a large oblong iron frame-work,

some seven feet wide, six feet high, and ten feet long. It stands

on a bit, of railway, built in for the purpose, close to the rock.

To the sides of this iron frame are clamped little gun-metal cylinders,

supplied with compressed air from the air tube running in from

the compressors outside the tunnel. To the ends of the extending

pistons of these little cylinders are fastened the long iron drills,

which are driven into the rock at the rate of 150 strokes each

per minute. There is no boring, in a proper sense; it is simply

drilling. A simple contrivance on the piston causes it to turn

over and over as the drilling progresses. These machines punch

holes into the rock about four feet deep, and are then moved back

to a safe distance, while the holes so pierced are filled with

long cartridges of dynamite to be fired by fuses. During the drilling

the noise of the machines is almost deafening. Nobody pretends

to hear a word. Every order is given by gesture. When the explosion

occurs it is not only a tremendous noise, but a tremendous heat

and smell as well, which even the stout miners could not long

submit to and live.

The compressed air is now allowed to escape from the cylinders,

the cocks to the main air tube are left open, and the foul odors

are gradually pushed to the rear. The debris is removed as quickly

as possible, the track for the machine is laid closer up to the

breast of the granite, and again commences the rattling of the

drills.

Under favorable circumstances this advanced gallery or heading

has been driven forward as much as eighteen or nineteen feet per

day at each end of the tunnel. The average, however, is not above

ten and a half feet per day, or twenty-one feet advanced for the

two ends.

The tunnel which I have been describing is, of course, the

main one of the series through these mountains. There are, however,

as has already been observed, others nearly joining it, some of

which are 6000 feet and more in length; and the sum total of what

might properly enough be called the tunnel of the St. Gothard

measures but little less than twenty-three English miles. Seven

of the tunnels in this series will be built in a spiral or auger

form, for the purpose of bringing the line up great elevations.

Passenger trains may thus enter the foot of a mountain, and, by

winding about in a sort of a railway staircase for a time, emerge

a couple of hundred feet higher up. There will be four of these

railroad stairways on the Italian side of the tunnel, between

Giornico and Fiesso. This method of taking trains up mountains

by means of spiral tunnels inside is the invention of Mr. Hellwag,

the engineer-in-chief.

There are probably 3500 persons, including officers, engineers,

draughtsmen, etc., engaged upon the tunnel. The common workmen,

as already noticed, are all Italians. Many of the officers and

engineers are Swiss; a few are Germans. Mr.Hellwag, the chief

of affairs, is a native of Schleswig-Holstein, and is a distinguished

railway engineer. Mr. Favre, the contractor, is a Swiss.

I have purposely omitted all mention of the Italian side of

the tunnel for the reason that the principle on which it is being

worked is exactly the same as is pursued at the Swiss side, and

the general control is in the hands of the same engineers.

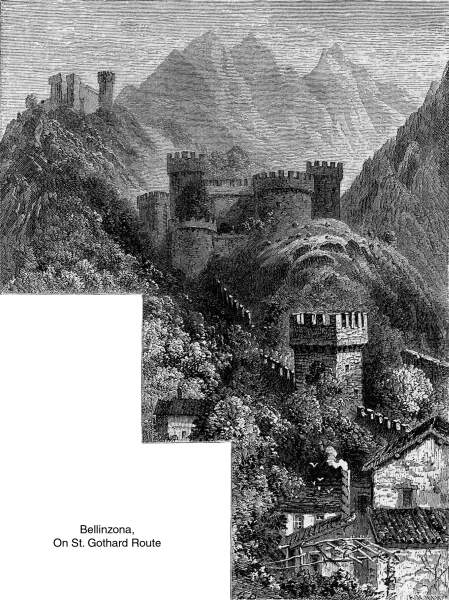

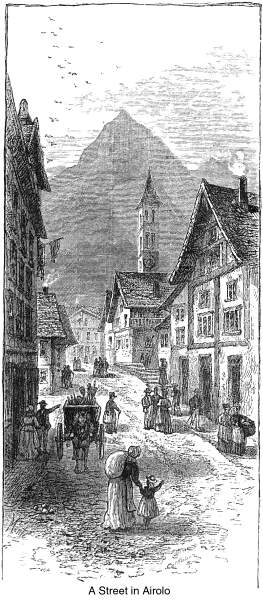

When the St. Gothard road is completed, it will, in some respects,

offer the most tempting railroad ride in the world. The scenery

through which it passes, especially at the Axenstrasse, on Lake

Lucerne, is as grand as any in Switzerland. It will pass within

a rifle-shot, too, of Rutli, Burglen, Altorf, and other spots

made famous by the deeds of Tell. Pretty little Airolo and castled

Bellinzona will be halting places, and trains will pass over mountain

spurs half as high as the Righi. A couple of short hours' ride

will take the traveller from the edges of the glaciers in Switzerland

down into the sunny plains of Lombardy; and should proper connections

be arranged, the Swiss merchant may go to bed in a Pullman car

at Zurich, and wake up with the early morning at Venice on the

Adriatic.

Mountain Railroading

| Contents Page

|