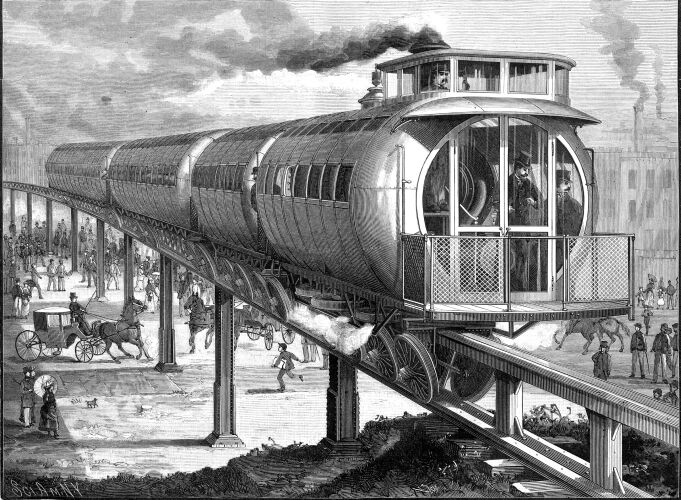

THE MEIGS ELEVATED RAILWAY.

Scientific American—July 10, 1886

The roadbed and rolling stock of the railroad of today have

reached their high standard through the labors of countless ingenious

and persevering inventors, each of whom has added his link to

make the chain more perfect; even the smallest detail shows the

combined talent of many industrious workers, one taking it up,

advancing it a step, and then giving place to another. It therefore

seems peculiar to be called upon to describe a new method of railroading

designed as a whole by one man—a new railroad from the ballast

to the top of the smokestack, from the pilot to the coupler on

the last car.

The system herewith illustrated is the invention of Mr. Joe

V. Meigs, of Lowell, Mass., and has been tested under conditions

far more exacting than would be found in actual practice. The

road is not a model, but a full-sized elevated railroad in every

respect. This was made necessary .by a section in the act of the

Massachusetts Legislature authorizing the incorporation of the

Meigs Elevated Railway Company, which states that "no location

for tracks shall be petitioned for in the city of Boston until

at least one mile of the road has been built and operated, nor

until the safety and strength of the structure and the rolling

stock and motive power shall have been examined and approved by

the board of railroad commissioners or by a competent engineer

to be appointed by them." To fully demonstrate the possibilities

of the road under widely varying circumstances, the company has

built tracks of several kinds—wooden way of the cheapest

possible kind; wooden way following the contour of the earth;

wooden way with level grade secured by varying the heights of

the posts; wooden way with very short curves and steep grades;

and iron way upon high grades, increasing in height until a level

of 14 feet in the clear above the earth was secured. The trial

road, beginning at the shops of the company on Bridge St., East

Cambridge, has one curve of 50 feet radius, 165 feet long, on

a grade of 120 feet, and on level and curves has grades of 240

feet, 300 feet, and 345 feet. So far everything has worked in

the most satisfactory manner, the train rounding the exceedingly

sharp curves easily, and mounting the steep grades without trouble.

The peculiar features of this road, wherein it differs roost

essentially front the ordinary railroad, are the way, switch,

trucks, passenger cars, engine, drawbar, and brakes.

The posts for an iron way are made up of two channel bars united

by two plates, thereby forming a box-like structure whose cross

section may be varied as demanded by location. The posts are to

be placed upon foundations, the plans of which vary to suit the

character of the material that may be encountered.

The way upon which the train runs consists of a single iron

girder 4 feet in depth for each span, placed over the center line

of the posts. The girder carries an upper track beam and a lower

track beam, upon the sides of each of which the rails, four in

number, are placed. The two bearing rails, which carry the load

of the train, consist of angle irons placed upon the outer upper

edge of wooden stringers upon the lower track beam. These stringers

are placed in the exterior recesses formed by two channel bars

properly secured to the sides of the posts. These rails are fastened

to each other, to the stringers, and to the track beam by bolts

passing clear through. Two vertically placed rails for the balancing

or friction wheels are carried by the upper track beam. The distance

from out to out between the lower rails is 22½ inches,

this being sufficient to insure the necessary transverse stiffness.

This is the gauge of the road. The distance between the upper

rails is 17½ inches. It is expected to adopt the common

form of rail, beveling the edges of the lower stringers and placing

the rail at an angle of about 45 degrees. In our engraving, the

rails are in the form of a right angle, and the treads of the

wheels are made with a corresponding right angle groove. The usual

length of post, 24 feet, would give a clear headway of 14 feet,

4 feet being taken up by the truss and 6 feet forming the foundation.

The switch is formed of a single swinging section turning upon

a hinge of great strength attached to one of the posts. A movement

of four or five feet by the free end of the switch is enough to

permit the cars and trucks on one track to clear the end of the

other track. The free end travels upon a carriage provided with

rollers moving upon a supporting rail. Suitable mechanism is provided

for operating the switch and locking it in place.

The truck is a development of the conditions controlling the

adoption of the permanent way. It consists of a horizontal rectangular

wrought iron frame, stiffened by cast iron pieces and provided

with stiff pedestals bolted to its under side, in which is a fixed

short axle for the wheels. Each truck has four wheels set at an

angle of about 45 degrees, the axles being properly inclined.

Between the supporting wheels are two horizontal wheels, one on

each side of the upper girder, upon vertical axles attached to

the frame; these wheel bear upon the rails of the upper truck

beam, and are kept in yielding contact with the rails by springs

outside the boxes, and serve as balancing wheels to take the side

oscillations of the cars. They are formed with flanges that pass

under the lower edges of the rails, thus tying the truck to the

rails, so that no lifting or jumping can take place, and there

is no possibility of the trucks running off the track. The wheels

are 42 inches in diameter, have a tread of 3½ inches, and

rotate independently of each other. In case any or all of the

wheels should break, provision is made to prevent the cars from

overturning or leaving the track, by means of a strong shoe, which

would slide upon but could not leave the way. On top of the truck

frame is a movable iron frame carrying four posts containing heavy

spiral springs. These posts interlock with similar spring sockets

bolted to the framing of the floor of the car, which is directly

above the truck and within 18 inches of the top of the girder.

The truck is guided in turning by a center pin, and is securely

tied to the car body, as the horizontal flanges of its frame castings

overlap the rim of the upper turntable. In passing curves and

switches, the trucks turn upon the balancing wheels, placed centrally

between the supporting wheels, which are 4 feet apart.

It has been found that, by reason of the independent motion

of all the truck wheels, curves are followed so closely that practically

the increase of friction of the cars upon curves even as small

as 50 feet radius is too slight to be noticed or measured by weighing

in a model one-eighth full size. This construction of the trucks

also admits of a car 50 feet long turning from a street only 28

feet wide into another of the same width.

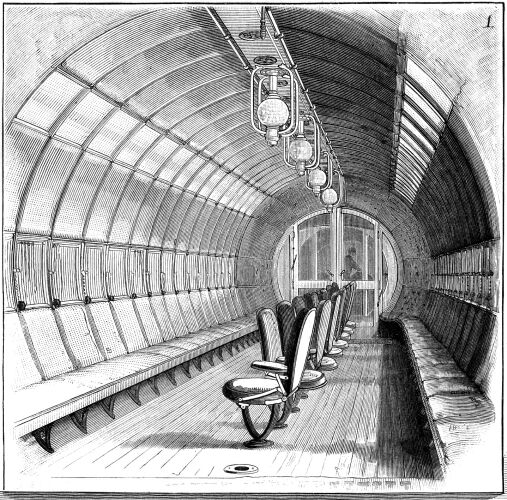

The cars possess

many novel features, both outside and inside. The circular section

and rounded ends admit of the strongest possible construction

without an overweight of material. The floor consists of a platform

made of 5 inch channel beams, and is 7½ feet wide by 51

feet 2 inches long. The framing of the body is of light T iron ribs, bent in a circle, filled

in by panels covered with rich upholstering, which covers all

the interior; the exterior is sheathed with paper and copper.

The cylindrical portion is 10 feet 8½ inches in diameter.

While adding to the strength, this form is expected to diminish

the wind resistance fully one-third. The interior of the car,

as shown in Fig. 1, is light, roomy, and pleasing to the

eye. The seats are upholstered like the rest of the car, and comfort

and luxury have been carefully studied in every detail. At each

window is a specially designed device for securing ventilation

without the annoyance caused by dust. There is an entire absence

of sharp corners, so that, in case of a serious accident, the

liability of the passenger being greatly injured is largely avoided. The cars possess

many novel features, both outside and inside. The circular section

and rounded ends admit of the strongest possible construction

without an overweight of material. The floor consists of a platform

made of 5 inch channel beams, and is 7½ feet wide by 51

feet 2 inches long. The framing of the body is of light T iron ribs, bent in a circle, filled

in by panels covered with rich upholstering, which covers all

the interior; the exterior is sheathed with paper and copper.

The cylindrical portion is 10 feet 8½ inches in diameter.

While adding to the strength, this form is expected to diminish

the wind resistance fully one-third. The interior of the car,

as shown in Fig. 1, is light, roomy, and pleasing to the

eye. The seats are upholstered like the rest of the car, and comfort

and luxury have been carefully studied in every detail. At each

window is a specially designed device for securing ventilation

without the annoyance caused by dust. There is an entire absence

of sharp corners, so that, in case of a serious accident, the

liability of the passenger being greatly injured is largely avoided.

The locomotive consists of a platform car supported upon a

truck at either end and housed like the passenger car. The floor

is 7½ ft. wide by 29¼ ft. in extreme length; the

tender is 24-and-two-thirds ft. long, has a tank and bin for the

water and coal, besides additional room which maybe used for other

purposes. Upon the floor of the engine are, in effect, two complete

stationary engines, each connected with a single driving wheel.

The boiler is of the locomotive type, is 60 in. in diameter, 15

ft. in length, and is placed over the engines, its center line

being 61 inches above the floor. There are 200 tubes, 2 in. in

diameter and 7 ft. long; the grate is 4½ ft. square. The

crown sheet is arched in shape, and is inclined downward at the

back end to allow of climbing and descending grades equal to 800

feet to the mile without exposing any uncovered part to the fire.

The cylinders are 12 by 22 in., and their center lines are placed

18 in. above the floor and 61 in. apart. The piston rods connect

with independent crossheads gliding upon steel girders supported

at their ends by standards bolted to the floor beams.

The driving wheels are 44.6 in. in diameter, flanged upon their

lower edge like the balance wheels of the trucks, and are mounted

upon steel axles 6 in. in diameter, which extend through a sliding

box containing the journals. The boxes slide in cast iron ways

placed at right angle to the line of the engine, and each axle

has a crank keyed upon its upper end. The well known slotted yoke

connection is used. The slide valves are of the usual locomotive

form. The links are placed in a horizontal instead of a vertical

position, and are operated by two bell cranks. The throttle valve,

link rod, brake, and coupling rods, and the connection between

the driving boxes for producing pressure against the rails, are

operated by hydraulic power, although hand levers are also provided.

Adhesion of the driving wheels to the rails is obtained by

means of a cylinder and piston secured to the sliding boxes. The

engineer is on an elevated platform in the front part of the engine,

the fireman being at the rear end. The former has an unobstructed

view through the windows of the monitor roof, and before him are

five hydraulic cocks, which control the throttle, links, sliding

boxes of the driving wheels, the brake, and the coupling rods

of the entire train, while just above are steam and hydraulic

pressure gauges and indicators, whistle and bell ropes, etc. With

an engine thus furnished with provisions for griping the rails,

steep grades become of minor importance, as the steepest possible

can be ascended if the requisite power is provided.

One turn of the cock controlling the couplings divides the

train into segments of separate cars, each of which has a brake

which acts automatically upon detachment from the train. This

partially destroys the momentum of the whole, and a collision

could only take place by a succession of comparatively light blows

from the engine and slowing sections of the train, instead of

by a single blow with the momentum of the whole train.

The brakes

are operated upon the balancing wheels of the trucks, but they

may also be fitted upon the supporting wheels. The action of the

brakes is well illustrated by rails between the rolls of a rolling

mill, except that the action is reversed. It is apparent that

no slipping of the wheels can take place, no matter what pressure

may be brought to bear upon them. The brakes

are operated upon the balancing wheels of the trucks, but they

may also be fitted upon the supporting wheels. The action of the

brakes is well illustrated by rails between the rolls of a rolling

mill, except that the action is reversed. It is apparent that

no slipping of the wheels can take place, no matter what pressure

may be brought to bear upon them.

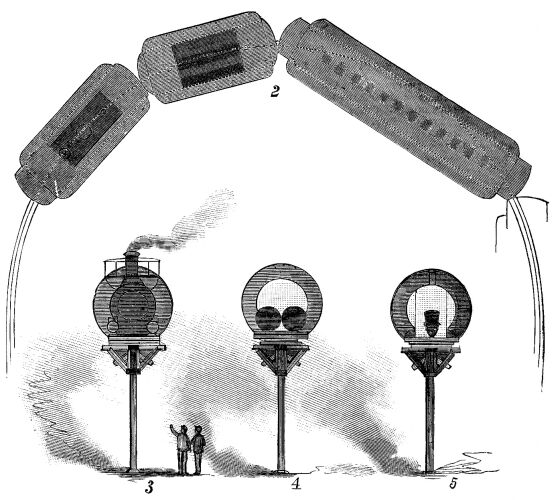

In the illustration, Fig. 2 is a plan view of a train

on a sharp curve, Fig. 3 is an end view of the track and

the engine, Fig. 4 is a section through tender and track,

and Fig. 5 is a section through the car.

From the foregoing it will be seen that this system is as applicable

for surface as for elevated railroads. It may be more cheaply

built than the ordinary road, as the construction of the rolling

stock allows the contour of the ground to be more closely followed.

As an elevated road in cities, the permanent structure presents

far less obstruction to light and air than the usual form. The

center of gravity of the cars and engine is brought as low as

possible, thereby lessening the effect of leverage caused by wind

pressure. The smooth, even surface of the exterior of the entire

train serves to decrease the resistance to the wind, and permits

a high rate of speed.

Oddities Page

| Contents Page

|