|

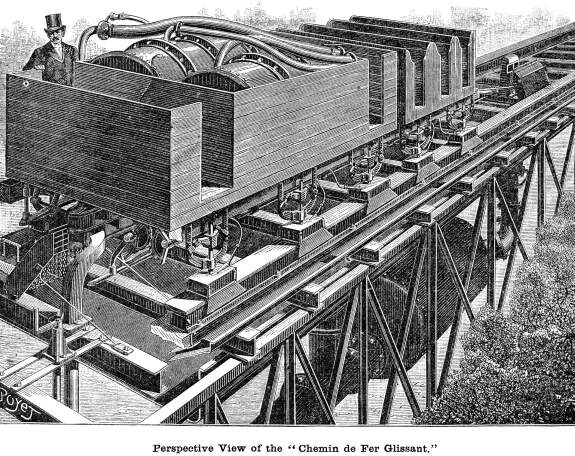

The "Chemin de Per Glissant,"

or Gliding Railway.

Engineering News—October 26, 1889

In our issue

of Aug. 31, a Paris correspondent gave to our readers sketches

and an excellent general account of this novel and promising method

of propulsion on railways now in operation in Paris. We supplement

this article by some further detail from Le Génie Civil

of Sept. 28, and reproduce from that journal a perspective

view which will better illustrate the general appearance of this

new hydraulic motor than anything we have given before. In our issue

of Aug. 31, a Paris correspondent gave to our readers sketches

and an excellent general account of this novel and promising method

of propulsion on railways now in operation in Paris. We supplement

this article by some further detail from Le Génie Civil

of Sept. 28, and reproduce from that journal a perspective

view which will better illustrate the general appearance of this

new hydraulic motor than anything we have given before.

The description of the operation already given was so complete

that we will only supplement it by giving some further collateral

data.

Among the first objections that are naturally made against

the method of M. GIRARD is the effect of

cold upon a system which rests entirely upon the use of water.

M. BARRE, the engineer, answers this objection

as follows: As all the liquid used in the various parts of the

machine is carefully gathered again for re-use, it is believed

that a regular service can be maintained in the climate of France

by a mixture of water with one-fifth part of glycerine. Even admitting

that the total loss would reach 1 per cent., the loss of glycerine

would only be 0.2 per cent. In place of glycerine the chloride

of magnesium may be used; the latter is cheaper than glycerine

and does not attack metal. A proportion of 1 of chloride to 7

of water would be sufficient.

If it is preferred to use the water alone, it would be necessary

then to protect, by non-conducting covering, the accumulators

and propulseurs, or motor jets. In the case of an elevated

metallic roadway these parts could be covered by wooden casing

placed between the girders. The reservoirs for the pumps could

be arranged in such a manner as to be heated in winter. With a

temperature of 5 degrees Fahr., for example, it would only be

necessary to raise the water to 61degrees Fahr. to permit the

whole apparatus to lie idle for 20 hours before the temperature

would fall to 32 degrees. The thin sheet of ice which would form

on the sides of the "rail," as it may be called, would

be melted, and removed by the water of the following train. The

only precaution necessary would be to detach the patins, or

slides, from contact with the rail after a long stop by circulating

through them for a few seconds a jet of steam before moving, from

the heating apparatus of the cars or otherwise In the case of

a line located upon the ground, the apparatus of propulsion would

be enclosed in a gallery placed either under the road or at the

sides.

As the movement of trains thus propelled is extremely easy

and produces no shock, it is alleged that the roadway may be placed

directly on the ground without any kind of ballast. [We doubt

this.-ED.] This feature, coupled with the ability to ascend steep

grades and pass around curves of short radius, enables the engineer

to practically follow the natural surface and to make the actual

construction very economical. The speed of these trains is very

considerable. There is no economical purpose in reducing it for

certain classes of traffic. In the case of curves, the friction

is no greater than on a straight line, for the trains reach the

curves always with the same velocity, and the rails can be so

inclined as to entirely destroy the centrifugal force,—a

result which cannot be reached in a combination of rails and wheels.

The important claim is justly made that in the cases of water

power of great volume and force found so often in mountain regions,

the expense of traction will be little more than that of selecting

and leading this power to the machine.

The advantages of the system are summed up by M. BARRE

as follows: (1) Ease of motion; no shaking and no lateral movement.

(2) No noise, dust, or smoke. (3) Derailment impossible, as no

foreign body can get under the shoes. (4) An almost instantaneous

stop without shock; as a consequence collisions may be easily

avoided. (5) Ease in ascending steep grades and passing around

curves of short radii. (6) A velocity touching 124 miles per hour,

with a pressure of 22 kilos. (313 lbs. per sq. in.) in the supplying

conduit. (7) Lightness of material in roadway, and consequently

economy in construction. (8) Considerable economy in the expense

of traction and in the weight and cost of carriages. (9) Notable

economy in repairs in the motive power. M. BARRE

estimates this latter item as being equal to 66 per cent., on

account of the reduction in the number of horse power necessary

to operate this machine, and because proper pumps for compressing

water move slowly and are not subject to the excessive shaking

and speed of moving parts incident to a locomotive in operation.

M. BARRE claims that the obstacles to

the system are included in the expense of the first plant, the

providing of considerable quantities of water, the action of cold,

etc.; not counting the obstacles as yet unforeseen which may arise

in practice. He claims that it is as easy to provide for the proper

supply of water to each shoe in use as it is to be assured of

the proper behavior of each wheel under an ordinary railway train.

Oddities

| Contents Page

|