|

SIBLEY COLLEGE LECTURES.—1887-88.

BY THE CORNELL UNIVERSITY NON-RESIDENT

LECTURERS IN MECHANICAL ENGINEERING.

II.—THE HUDSON RIVER BRIDGE AT POUGHKEEPSIE N. Y.

By THOMAS C. CLARKE C.E.

GENERAL DESCRIPTION.

MODERN bridge building is the creature of the railway system

and its productions are as different from the stately stone arches

of our ancestors as is a locomotive from a Greek chariot.

There we now 150,000 miles of railways in the United States

and it is estimated that there is at least one bridge of 100 ft.

long to every mile. This gives over 2,800 miles of bridges, chiefly

of iron and steel. Where so many have to be built in a short time,

aesthetic considerations are little regarded. Utility alone governs

their design. So long as they are strong enough, few care how

they look.

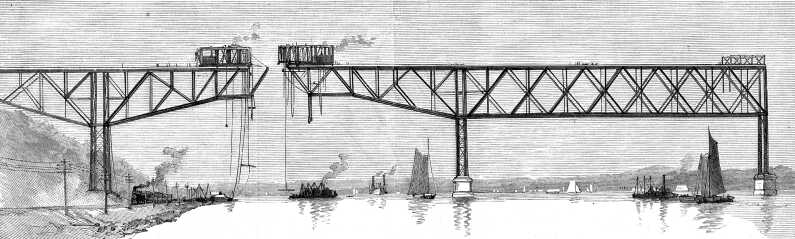

I make these preparatory remarks before showing you a view

of the bridge now building across the Hudson River at Poughkeepsie,

N. Y., by myself and my associates, to prepare your minds for

the fact that it is not "a thing of beauty " although

we hope it may be "a joy forever" to its stockholders.

It is, however, a considerable

piece of engineering. It is one of the great bridges of the world.

The work of construction has been carried on with extraordinary

rapidity, and serious difficulties have been successfully overcome

in putting in the foundations, which go down to 130 ft. below

tide. It is, however, a considerable

piece of engineering. It is one of the great bridges of the world.

The work of construction has been carried on with extraordinary

rapidity, and serious difficulties have been successfully overcome

in putting in the foundations, which go down to 130 ft. below

tide.

The object of this bridge and of its connecting railways is

to deliver coal into the interior of Massachusetts and other New

England States as cheaply as it is now delivered by water to the

seaboard towns.

There will be a considerable saving in the east of freight,

and an avoidance of two transshipments, each of which injures

the value of the coal from 5 percent to 10 percent.

This will develop the manufactures of the interior towns and

cities, just as those of the seaboard towns have been developed

by cheap fuel.

Heretofore the Hudson River has stood in the way—a formidable

barrier, both legal and physical.

As a legal barrier, it was removed when the legislature of

the State of New York grasped the idea that those who wish to

cross a river have equal rights with those who wish to go up and

down it.

As a physical barrier, it was removed when we learned to build

bridges of 500 ft. span and over.

The navigation of the Hudson is chiefly carried on in canal

boats, which are united, forming a mass often 150 ft. wide by

700 to 800 ft. long, and consisting of 70 to 80 boats in number.

These are towed by powerful steam tug boats called "big tows."

I have seen three to eight large tows pass every day. None had

the slightest difficulty in passing. I have seen three tows pass

together through one span, although partly blocked by our own

construction, barges. There will be five spans available when

the bridge is finished.

The, Hudson is a great trough, about half a mile wide, lying

from 800 to 500 ft. below the general level of the country on

each side. At Poughkeepsie, it has 60 ft. of water, and 70 ft.

of mud and silt. Below this there is a deposit of very hard gravel

and boulders of varying depth, and the rock is found at from 150

to 200 feet below tide level.

As the banks and the country on each side are so high above

the stream, it was necessary to build the bridge 212 feet above

water, and place the rails on the top of the bridge.

The river part consists of:

Three cantilever spans of 548 feet each

Two connecting spans of 525 feet each

Two shore spans of 201 of feet each

Total length of river bridge 3,094 ft., besides which then

are viaduct approaches on each side, making a total length of

about one mile and one-third

FOUNDATIONS.

A pier is an artificial island. There are three ways of making

them. One is the old fashioned plan of inclosing part of the river

with a water tight structure called a coffer dam, pumping out

the water, and building upon the bed of the river so laid dry.

This can be carried to about 30 feet in depth.

Another method is by using compressed

air. The pier is carried by an inverted box called a caisson,

made of wood or iron, placed in the water open side downward.

Air is pumped in and the water is driven out, and men go down

inside by means of a contrivance called an air lock. This method

be carried to a depth of about 100 feet. After that the pressure

of the air becomes so great that men cannot work without injury

to their health, and even loss of life. Another method is by using compressed

air. The pier is carried by an inverted box called a caisson,

made of wood or iron, placed in the water open side downward.

Air is pumped in and the water is driven out, and men go down

inside by means of a contrivance called an air lock. This method

be carried to a depth of about 100 feet. After that the pressure

of the air becomes so great that men cannot work without injury

to their health, and even loss of life.

As the necessary depth required to reach hard bottom at Poughkeepsie

was 130 ft. we were obliged to adopt a third plan, and do all

our work under water and without removing the water.

Had there been no mud and clay overlying the hard material,

this would have been comparatively easy. We would have sunk a

bottomless box or crib of timber, down through the water, until

its sides rested on the hard bottom. We would then have placed

in concrete, which is an artificial stone which has the property

of hardening under water, and becoming a monolithic mass. Once

in that condition, the timber box might decay or be removed without

impairing the strength of the pier.

But as there was 70 ft. of mud and clay to go through besides

60 ft. of water, we had to modify this plan by making our crib

with double sides, and with a double partition through the center.

These sides were united by a timber bottom placed at an angle

so as to form a cutting edge. We then filled the spaces with gravel

to give the necessary weight. We then dredged out the mud and

clay with the dredge.

As fast as the clay was removed the crib would slowly sink,

and we would continually put new timbers on the top and fill In

more gravel. At last the lower cutting edge reached hard bottom,

and would go no farther. We then dredged out all the clay remaining

inside and then filled the spaces with concrete put down by the

mixer.

This was a very efficacious machine. We could with two of them

put in 300 to 400 yds. per day, and were able to fill the crib

with concrete in less than a mouth.

We had thus made an artificial island, but its top was 16 ft.

below water. We first leveled up the surface of the concrete,

by means of divers using submarine armor. We had previously built

a great scow or barge, with a bottom of six courses of foot square

timber well bolted together. This was floated over the crib, the

masonry pier built on it, until its weight gradually sunk it down

so that the bottom rested on the crib island. The sides were then

removed and the pier built up to 30 feet above water.

For 100 feet higher the pier is built of steel columns well braced

together. There seems to be no reason why the steel is not equally

serviceable when placed vertically as horizontally. The saving

of weight amounts to from 700 to 800 tons, while the saving of

time is still more remarkable. A stone pier 100 feet high would

take four months to build. A steel pier 100 feet high can be erected

and secured together in four days. This is one example of the

great rapidity of modern methods of construction over those of

former times.

The pressure upon the concrete is about six tons per square

foot, and it is safe to sustain 100 tons. The piers above water

are all made of concrete faced with cut stone. I prefer this kind

of masonry to rubble, as being monolithic and much stronger. It

can be done more rapidly, and costs no more. The composition is

one part Portland cement to three parts sand, which forms a mortar

to which is added six parts broken stone or screened gravel. This

kind of masonry was invented by the Romans. The dome of the Pantheon

is a monolith, built in this way. It is like a dish cover. It

has no joints to be shaken apart by earthquakes. I remember seeing

workmen tearing down old buildings in Rome to open the Via Nationale.

The mediaevel masonry of rubble offered little resistance to the

crowbars of the workmen, but when they came to the Roman walls

of concrete, they had to drill and blast with dynamite.

The Emperor of Russia awarded the construction of railways

and their equipments to American engineers—the Winans, of

Baltimore. Since that time I know of no instance of engineering

works being awarded to Americans by any foreign government, on

account of the superiority of their designs, until the Australian

bridge was awarded to us. We had to compete with engineers from

this country, from Britain, France and Germany. There were some

sixteen plans submitted in all, varying in price from $1,500,000

to $3,500,000.

A commission of English engineers of the highest standing examined

all these designs very carefully, and recommended ours for adoption,

on the ground that it was absolutely the best, although not the

lowest in cost.

We have put in four out of six foundations successfully, and

hope to finish the bridge ready to cross trains by the end of

this year.

I wish to add here that, unless this commission of English

engineers had shown the utmost spirit of fairness, and had recognized

that science knows no national boundaries and is hampered by no

tariffs, we never should have been awarded the work.

SUPERSTRUCTURE.

A great advance was made in bridge building when rolled iron

was substituted for brick, stone, and wood. An even greater advance

was made when the properties of the metal known as "mild

steel" became recognized and it was applied to the construction

of bridges. The specification of this quality of steel, which

is used in Poughkeepsie bridge, is:

Ultimate strength 60,000 to 65,000 lb. per sq. in.

Elastic limit ½ of ultimate.

Elongation in 12 inches 25 per cent.

Reduction of area at point of fracture 40 to 50 per cent.

This material can be depended upon for uniformity. It

is not "treacherous." That evil quality is confined

to a hard steel, having high percentage of carbon, and whose net

strength runs from 80,000 to 100,000 lb. per sq. inch. Let those

who dare use it for bridges. I am not one of the number.

The Poughkeepsie bridge is proportioned to carry the heaviest

coal trains on both tracks at once, drawn by two consolidation

engines. A wind pressure of 32 lb. per sq. foot on all exposed

surfaces (sufficient to blow trains off the bridge) is provided

for.

The maximum strains have a combination of all these pressures:

Maximum tension 15,000 lb. per sq. in.

Maximum compression 14,300 lb. per sq. in.

Least tension 5,700 lb. per sq. in.

Least compression 6,375 lb. per sq. in.

The strains are proportioned according to the actual ratio

between dead and moving loads. The bridge will be laid with two

tracks of 70 lb. steel rails, with Fisher joint, guard timbers,

and Latimer guards at each end.

TEMPORARY STAGING AND METHODS OF ERECTION.

Where there is such a great depth

of water and mud, and where the height of the bridge above water

is so great, temporary staging, such as is used for erecting ordinary

spans, becomes very expensive and takes a long time to build. Where there is such a great depth

of water and mud, and where the height of the bridge above water

is so great, temporary staging, such as is used for erecting ordinary

spans, becomes very expensive and takes a long time to build.

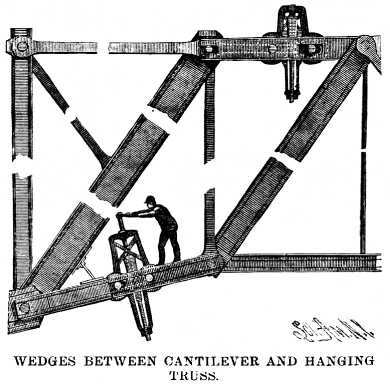

Hence the use of cantilever spans, which are built entirely

from above by means of traveling scaffolds, projecting over and

pushing forward day by day. The weights of the scaffold and of

the projecting spans of the bridge are prevented from tipping

over either by anchorages or by the weight of the connecting spans

themselves.

The question is sometimes asked if there is a saving of weight

in cantilevers. There is not. It is in this case heavier by about

10 percent than disconnected spans would have been, but there

is a saving of three very costly stagings and of a great deal

of time.

It takes from three to four months to put up one of

these stagings and the steel structure upon it. It takes from

three to four weeks to put up a cantilever span of greater

length.

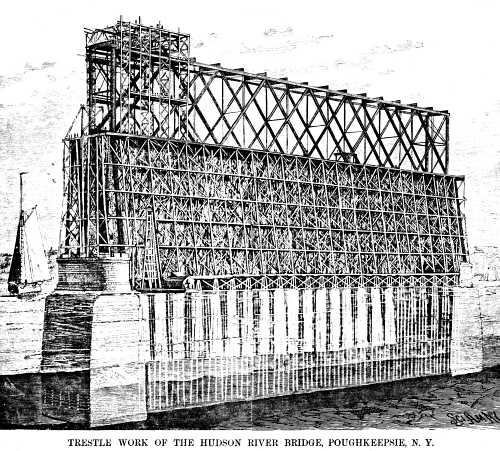

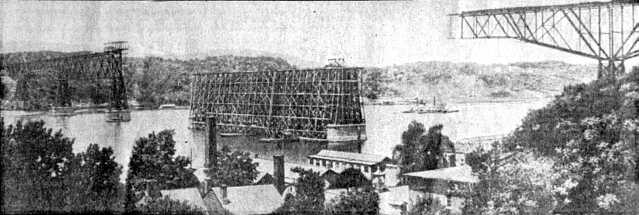

TRESTLE WORK.

One of the largest and most successful pieces of timber trestle

work executed in this country is that designed to support the

two fixed spans of the Poughkeepsie bridge which connect the three

cantilever spans.

The depth of water is 60 ft., and below that there is a depth

of about 70 It. of soft mud and dirt. The trestle has been designed

to be erected on piles, and after erection of the first span,

the trestle taken down, and the piles all drawn out of the river.

This has been successfully done, and the same piles will be driven

again. They will require from 10 to 20 blows of the 3 ton hammer,

falling 10 ft., to break the bond of the mud. This process was

used before pulling each pile, which was done with double, sometimes

treble falls capable of exerting a force of at least 25 tons.

Not the slightest evidence of settlement was seen in this trestle.

If there had been any, it would have shown itself by a difficulty

in moving the great traveler, which weighs about 90 tons.

It has been found possible to pull 90 percent of the piles

without breakages.

The trestle work itself is built of white hemlock, except the

caps, which are of yellow pine, and the longitudinal braces, which

are of white pine. It was framed with bolt joints, connecting

splices of 2' oak plank, and iron ¾" screw bolts.

It is 500 ft. long, 120 ft. high, above the piled foundation,

and 110 feet wide on the base, and 75 ft. wide on top.

The traveler is 73 ft. high. The total height from bottom of

piles to top of traveler it, 340 ft., or about 20 ft. less than

the height of Trinity Church Steeple, in New York. It has been

subjected to some winds strong enough to blow down chimneys, but

never has shown the least signs of vibration. Without counting

time lost by delays, it is about a three months' job to drive

the piles, build staging, erect steel work, take down staging,

and draw out the piles. This, however, requires a perfect organization

and the best kind of machinery in ample quantities, all of which

have been furnished by Ross, Sanford & Baird, the contractors

for this work to the entire satisfaction of the Union Bridge Co.

The general design of this trestle was fixed by mutual consultation

with the members of the Union Bridge Co. and Messrs. Row Sanford

& Baird. The plans were then made in the Buffalo shops, and

all the strains from gravity and wind pressure upon all the parts

and connections were calculated, and the parts duly proportioned

just as if it had been a permanent railway trestle The approximate

quantities of material in this work are:

Timber 1,000 M ft. B. m.

Iron bolts 200,000 lb.

Piles, 130, 135 ft. long 528

One of the most interesting things connected with this work

is the fact that spliced piles, about 18 in. at the butt, carry

9 tons each, at an unsupported length of 70 ft.

Poughkeepsie Bridge | Bridge

Page | Contents Page

|