Wrought-Iron Deck Turntable.

Engineering News—December 21, 1889

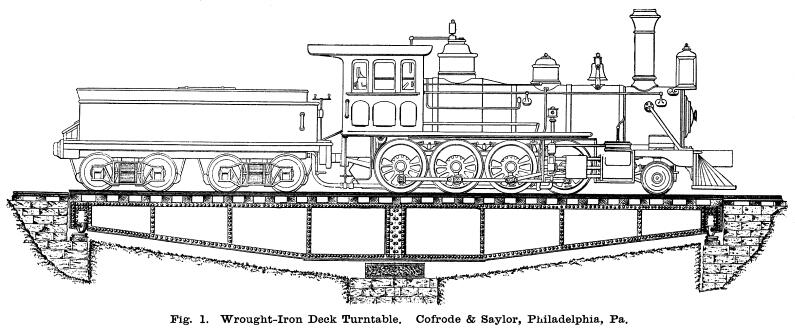

The accompanying cuts illustrate a type of wrought-iron deck

turntable for locomotives, as manufactured by Cofrode & Saylor,

of the Philadelphia Bridge Works, and patented in 188'7 and 1889

by Mr. F. H. SAYLOR, C. E., of the firm named.

In this turntable the main carrying girders are solid-web riveted

girders with angle-iron lateral and diagonal bracing. The cross-girders

are also made of plates and angles firmly riveted to the main

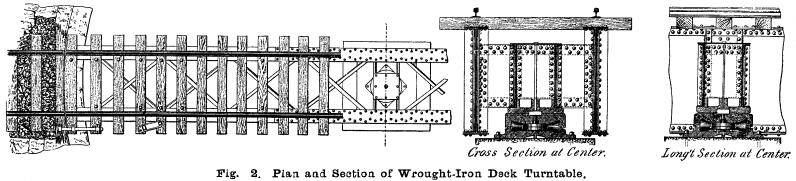

girders, as shown in Figs. 1 and 2. The construction of the center

pivot can best be understood by an inspection of the sections

shown in Fig. 2. The upper casting of this pivot has a square

projection on top planed so as to fit inside the box formed by

the cross-girders, to which latter it is firmly bolted. The middle

casting forms the top of the roller-box, and its top is planed

to a flat cylindrical surface, having its axis at right angles

to the table and accurately fitting the lower surface of the top

casting. A wrought-iron key is inserted between these plates to

prevent the two surfaces from sliding upon each other.

The special feature of the center pivot is found in this arrangement

of the two upper castings. The tendency of the table to tip laterally

is prevented by the horizontal cylindrical surface, which is about

20 ins. in width. The table can, however, tip slightly longitudinally,

so that when the locomotive runs upon it the trailing wheels bear

upon the circular track; but whenever the center of gravity is

within 16 ins. of the middle of the table, a full bearing surface

is furnished, and the tendency of the trailing wheels at both

ends is to rise clear of the circular track, and to remain so

while the table is being turned.

Steel plates, made to fit exactly the planed conical surfaces

of the lower and middle castings constituting the roller box,

provide bearings for the conical rollers.

Between these steel plates are chilled iron conical rollers,

ground to exact size, each 6¼ ins. in length almost completely

filling the roller box. In addition to these conical rollers there

are two hardened steel bearing plates, the lower being doweled

to the base casting and the upper provided with oil grooves to

insure free turning. The roller box is oiled through a wrought-iron

pipe extending through a plate iron cover on top of the cross

frame.

The lower half of the roller box constitutes the base plate,

and is 2 ft. 8 ins, square, with slightly rounded corners, and

is provided with four bolt holes 2 ft. 2 ins. apart, center to

center in each direction. These four holes are intended to receive

four wedge bolts 1-and-an-eighth in. in diameter, let into the

center bearing stone. The bolts should have 2-in. projection above

the stone to the under side of the nut. The center bearing stone

should not be less than 3 ft. square. All the parts of the center

pivot are made to exact gauge, so that they can be duplicated

at any time; they are the same size for all tables.

The vertical adjustment of the table is provided in a very

simple manner; there are no screw bolts for adjusting the height

at the center; this can be most readily accomplished by a wrought-iron

plate between the pivot and the masonry, should it at any time

be required. The adjustment at the ends of the table is provided

by simply changing the number of thicknesses of the packing plates

which are inserted between the journal boxes of the trailing wheels

and the channel iron cross-girders which carry these, whereby

the height of either of the trailing wheels above the circular

track can be fixed as desired. All tables are provided with four

packing plates, three-eighths-in. thick, for each journal box.

Two cast-iron sockets for wooden levers, and two latches are furnished

for each table.

This standard turntable is proportioned for turning an 86-ton

consolidation locomotive, or an equivalent load. and they are

turned out in lengths varying from 35 ft. to 75 ft. In a following

issue we will show a half-through wrought iron turntable as made

by the same firm.

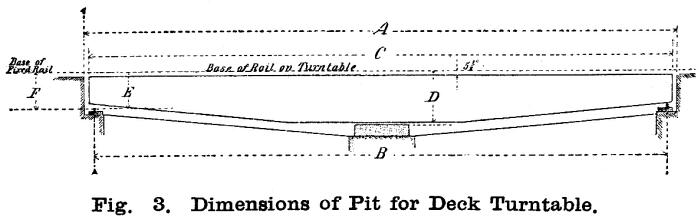

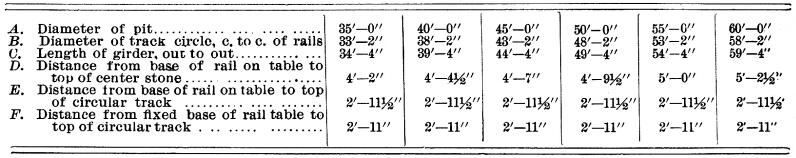

A useful table of dimensions of pits, for turntables adapted

to lengths varying between 35 ft. and 60 ft., is issued by the

firm named, and is given herewith.

Structures

| Contents Page

|