The Westinghouse Interlocking Switch

and Signal System

Scientific American—May 3, 1890

Some weeks ago we illustrated the electro-pneumatic block system

of train signaling. In our present issue we present our readers

with illustrations of some of the salient points of the Westinghouse

interlocking switch and signal mechanism for use in  train

yards. It includes three operating agencies, electricity, pneumatic

pressure, and hydraulic pressure. The work of throwing switches

and of setting signals at safety is done by pneumatic pressure.

The valves for regulating its action on signals are worked by

electricity exactly as in the block system already described.

The valves for regulating its action on switches are moved by

hydraulic pressure. train

yards. It includes three operating agencies, electricity, pneumatic

pressure, and hydraulic pressure. The work of throwing switches

and of setting signals at safety is done by pneumatic pressure.

The valves for regulating its action on signals are worked by

electricity exactly as in the block system already described.

The valves for regulating its action on switches are moved by

hydraulic pressure.

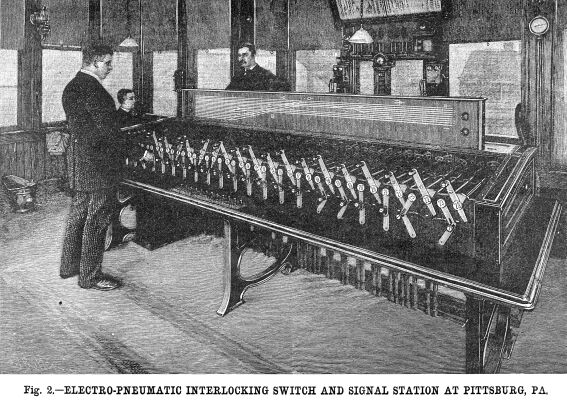

Referring to the perspective view of the switch board, it will

be seen to be a case upon whose front are two rows of handles.

These handles, when moved by the operative, turn through an arc

of a circle long vulcanite-covered spindles that run to the back

of the case. These spindles are numbered in pairs of similar numbers,

those to the left are rotated by the lower handles, those to the

right by the upper handles. On the rear end of each spindle is

a quadrant with locking detent, worked electrically. The upper

row of handles operates the switches; the lower row operates the

signals.

At the rear of each switch spindle, that is to say of every

second one, is a three-way cock attached directly to the spindle,

and therefore turned by the upper handle appertaining to the spindle

in question. This cock is a part of the hydraulic system. Turned

to the right, it operates by hydraulic pipe connections a valve

in the neighborhood of a switch which may be a mile or more distant.

The operation of this valve, which is connected to pneumatic pipes,

admits compressed air to the actuating cylinder and piston, and

throws the switch in one or the other direction. The switch-throwing

mechanism will be described later on.

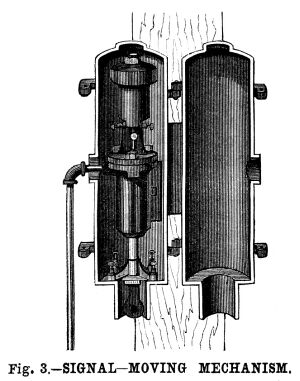

When a current of electricity

is passed through the actuating magnet of the signal-moving mechanism,

Fig. 3, which also may be at any distance, it opens a pneumatic

valve, admitting air to the signal-actuating cylinder, placed

on the semaphore post. The piston is forced outward and the semaphores

are depressed to the safety position. This current is sent through

the switch board, when the handles are set in proper position

therefor. On each of the vulcanite-coated spindles are placed

strips of platinum, and between the spindles are pairs of contact

springs. These, with their connections, can be arranged in any

way whatever to suit the conditions of the case. The circuit,

including the semaphore magnet, is completed through one or more

of these spindle connections. Hence the setting of any given semaphore

at safety may be made to depend upon one or more switch movements,

as necessary. After the switch handles in its series are properly

set, they complete their part of the circuit by means of the platinum

strips and springs. Then the final turn of the signal handle moves

its spindle into position and the circuit is completed, and the

semaphore descends to "safety." When the switches are

to be changed, the signal circuit has first to be broken. This

permits the air valve to close automatically, and the semaphore

rises by the influence of its counterweights to "danger."

The switches can then be moved as required. At the bottom of each

signal-moving mechanism Fig. 3, is a circuit closer. This keeps

a circuit closed as long as the semaphore is at danger. It is

an independent circuit and works the locking of one of the quadrants

on the rear of the signal handle spindles. When a current of electricity

is passed through the actuating magnet of the signal-moving mechanism,

Fig. 3, which also may be at any distance, it opens a pneumatic

valve, admitting air to the signal-actuating cylinder, placed

on the semaphore post. The piston is forced outward and the semaphores

are depressed to the safety position. This current is sent through

the switch board, when the handles are set in proper position

therefor. On each of the vulcanite-coated spindles are placed

strips of platinum, and between the spindles are pairs of contact

springs. These, with their connections, can be arranged in any

way whatever to suit the conditions of the case. The circuit,

including the semaphore magnet, is completed through one or more

of these spindle connections. Hence the setting of any given semaphore

at safety may be made to depend upon one or more switch movements,

as necessary. After the switch handles in its series are properly

set, they complete their part of the circuit by means of the platinum

strips and springs. Then the final turn of the signal handle moves

its spindle into position and the circuit is completed, and the

semaphore descends to "safety." When the switches are

to be changed, the signal circuit has first to be broken. This

permits the air valve to close automatically, and the semaphore

rises by the influence of its counterweights to "danger."

The switches can then be moved as required. At the bottom of each

signal-moving mechanism Fig. 3, is a circuit closer. This keeps

a circuit closed as long as the semaphore is at danger. It is

an independent circuit and works the locking of one of the quadrants

on the rear of the signal handle spindles.

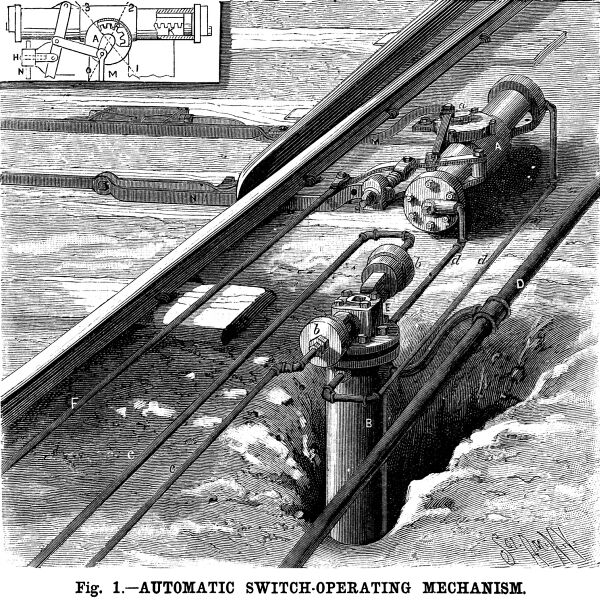

This, in connection with our former article, is enough to show

how the signals are operated. The switch-throwing mechanism has

now to be described. This is placed by the side of the track,

near the switch. It is shown in Fig. 1. The hydraulic tubes, c

c, connect with two cylinders, b b, and force the pistons

one way or the other, according to the position of the three-way

cock in rear of the switch board. At B is a reservoir, kept charged

with compressed air by the regular air pipe, D. At E is a D-valve,

exactly such as used in a steam engine, and which admits the compressed

air into either one of the pipes, d d, and puts the other

one of these pipes in communication with the open air. At A is

a double cylinder with two pistons, connected by a rack and working

a pinion. The partial section is shown in the upper left hand

corner of the cut, in which K is the rack and A is the pinion.

The air admitted by one of the pipes, d d, forces the pistons

in one or the other direction, regulated by the D-valve, thus

turning the pinion. As the pinion turns it carries around with

it an arm attached to its spindle, a. In its revolution

through about three-quarters of a circle the pinion has to successively

perform the following operations: 1. To withdraw the locking bolt,

H, from the hole in the locking bar, N; 2, throw the switch, by

moving the rod, M; 3, return the locking bolt, H, to the other

hole in the locking bar, N.

Referring to the sectional view,

H is the locking bolt, N the locking bar, and M is the switch

rod. If air is admitted to the right hand end of the cylinder,

the other end communicating with the open air; the pistons will

move to the left. The movement of the pinion may be divided into

three phases, indicated by the dotted lines. Moving from 0 to

1 it withdraws the lock bolt, but practically does not move the

switch bar, or at least only back and forth through the versed

sine of the arc described by the crank pin between 0 and 1. From

1 to 2 the relations are changed; here the switch rod is moved

through a longer distance, corresponding to the chord of the arc,

1-2, throwing the switch, while the lock bolt is only drawn back

and pushed forward a trifle corresponding to the versed

sine of the same arc, 1-2. From 2 to 3 the first relations are

re-established; the lock bolt is thrust forward into the hole

in the lock bar and the switch is hardly moved at all. A detector

bar is worked simultaneously with the lock bolt by means of the

rod, F, of the perspective drawing. Referring to the sectional view,

H is the locking bolt, N the locking bar, and M is the switch

rod. If air is admitted to the right hand end of the cylinder,

the other end communicating with the open air; the pistons will

move to the left. The movement of the pinion may be divided into

three phases, indicated by the dotted lines. Moving from 0 to

1 it withdraws the lock bolt, but practically does not move the

switch bar, or at least only back and forth through the versed

sine of the arc described by the crank pin between 0 and 1. From

1 to 2 the relations are changed; here the switch rod is moved

through a longer distance, corresponding to the chord of the arc,

1-2, throwing the switch, while the lock bolt is only drawn back

and pushed forward a trifle corresponding to the versed

sine of the same arc, 1-2. From 2 to 3 the first relations are

re-established; the lock bolt is thrust forward into the hole

in the lock bar and the switch is hardly moved at all. A detector

bar is worked simultaneously with the lock bolt by means of the

rod, F, of the perspective drawing.

Referring again to the cut of the switch board, a series of

studs or latches are seen projecting through holes below the switch

handles. These, if moved upward, catch the lower projecting ends

of the switch handles. They are raised and lowered by the agency

of the signal handles. As each of these is moved it throws a notched

bar that runs parallel to the face of the case to the right or

left. The bar, according to the arrangement of the notches, throws

upward or permits to drop any one or more of the latches. When

raised a latch locks the lever above it, when depressed it frees

it. Thus a mechanical interlocking of switch and signal handles

is provided that by different disposition of notches may make

the movements of one or more switch handles depend upon the movements

of any given signal handle.

On the rear end of each signal spindle on the switch board

is a quadrant which swings to right or left as the spindle is

rotated. This has teeth in which a latch engages. This latch is

operated by an electro-magnet in the rear included in the independent

signal circuit just described. When the signal is at "safety,"

this circuit is open, and the magnet not attracting its armature,

the latch, by gravity, locks the quadrant as to allow only a small

degree of movement to the signal handle with its spindle. This

movement is enough to close the main circuit and thus release

the semaphore, which rises to "danger," but not enough

to lower the interlocking latch or latches projecting from the

front of the case, until the semaphore has risen the full distance

to "danger." As it reaches this position the auxiliary

or locking circuit is closed, the magnet attracts its armature,

drawing the quadrant latch out of engagement with the quadrant,

and the handle can now be swung clear over, unlocking the switch

handles dependent upon it.

On the rear end of the switch spindle in the switch board are

similar quadrants, whose locking latches are actuated by an electro-magnet

connected with the circuit breaker on the switch-throwing mechanism.

At the end of the locking bolt, H, of this mechanism, Fig. 1,

is a circuit opener. When the bolt is in place and the switch

locked as shown, the circuit is open. This opener is in circuit

with the electro-magnet back of and actuating the quadrant-locking

latch appertaining to its own spindle on the switch board. This

is so constructed that a limited movement only is allowed when

the circuit is open. This movement is enough to turn the three-way

cock. The switch begins to move. As the locking bolt, H, Fig.

1, comes back, the circuit closes. The magnet attracting its armature

unlocks the quadrant and instantly relocks it. This is done so

quickly that the handle cannot be moved during the change. The

switch continues its movement. As it is thrown and locked, the

circuit opens, the quadrant is free, and the handle can be swung

clear over. Its first movement was only sufficient to open the

cocks, but not enough to close the signal-actuating circuit by

the strips of metal on its spindle. This is done by the second

motion. Hence as the signal cannot be moved until this circuit

is closed, and as a semaphore cannot be set at safety without

this closing of circuit, the protecting semaphore cannot be set

at "safety" until all the switches in its system have

been completely thrown and locked by the regular locking bolt.

Above the case containing the switch and signal handle mechanism

and connections, and facing the operator, is a miniature model

of the tracks and switches controlled by the switch board. The

model has movable switches, so that at a glance the operator can

see what position every switch in the system occupies. An annunciator

drop is also placed in view of the operator. This is worked electrically

by any train approaching the system, which train causes a bell

to ring and also drops the shutter when it is within a mile of

the track yard.

Safety Devices

| Contents Page

|