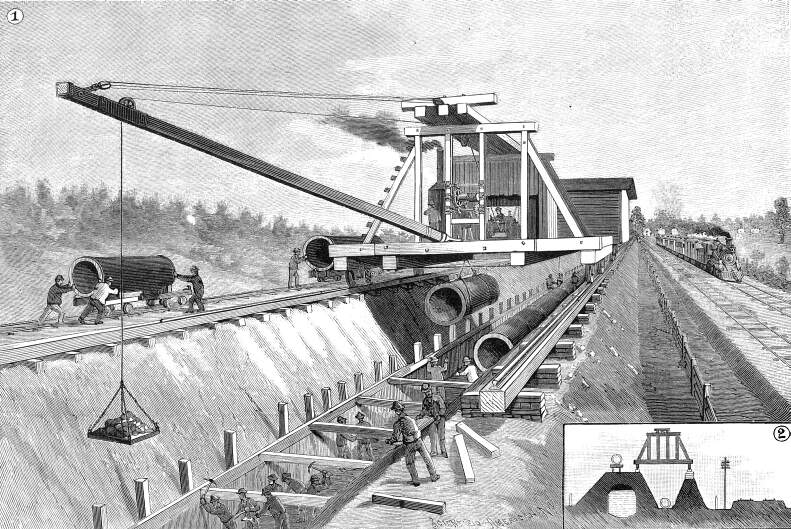

EXCAVATING AND PIPE LAYING APPARATUS

IN USE ON THE BROOKLYN AQUEDUCT

Scientific American—January 3, 1891

Fig. 1—Excavating and Pipe Laying Plant

at Work —— Fig.2—Section of Aqueduct, New Pipe

Line, and Pipe Laying Plant

The operation of laying large pipe lines has hitherto been

conducted by rather primitive appliances. The operations have

generally been to a great extent manual, and little more than

a derrick placed over the trench for swinging the pipes into place

has been used in the way of machinery. The labor of laying such

mains has been very severe, and progress necessarily slow, as

the work is limited to one point of attack. To secure a consecutive

line without sleeve connections the work must be advanced length

by length, always in the same direction and without intermediate

portions being laid in advance. The apparatus we illustrate has

been used with great success upon the Brooklyn, N. Y., water works,

in laying a new line of forty-eight inch pipes. As the sections

or lengths of pipe weigh from 7,000 to 8,000 pounds each, the

capacity of the machine has been somewhat severely tested. It

has, however, worked most successfully, laying from two hundred

to three hundred feet per day.

The apparatus consists in general of a hoisting apparatus and

crane followed by a lead-melting plant, all moving over the trench.

The two are separate and independent of each other's movements.

They are carried by rails, a single line of which runs along each

side of the trench. In advance of the whole arrangement the excavation

is kept in progress. The trench diggers work as long as practicable

by throwing the earth out by hand. As the depth increases, the

crane carried in advance of the hoisting plant is brought into

play. It is used to elevate the earth from the trench and to swing

it to one side. This operation is shown in Fig. 1 of the engraving.

As fast as necessary, the apparatus is moved forward on the rails

by pinch bars.

Along one side of the trench a portable railroad has been laid.

This serves for cars to run upon to carry off the dirt from the

excavation where necessary, and to bring pipes to be laid in the

trench. In Fig. 2 of the engraving the relations of trench, pipe-laying

plant, and portable railroad are clearly shown. Below the pipe-laying

apparatus the new line of water main is indicated lying at the

bottom of the excavation.

The pipes, as fast as required, are run up to the scene of

operations upon the portable railroad. The hoisting apparatus

consists in general terms of a rectangular platform carried on

four wheels and extending over and across the trench. Through

its floor a longitudinal opening is arranged, directly over the

center of the excavation, large enough for a pipe to pass through

in a horizontal position. The superstructure serves as support

for the jib tackle of the crane and to carry pulleys, etc., for

handling the pipe. As the length of pipe is run alongside, skids

or short timbers of wood are laid from the car to the platform,

and a pair of skids are also laid across the opening over the

axis of the trench. Two or more ropes are brought from the platform

to the car, passing under the pipe and then partially around and

over it, returning to the upper framework. At this point they

pass through pulleys and are brought to the floor, where there

is a steam windlass, which is seen mounted on the platform. On

drawing in the ropes, the pipe, it is obvious, will be rolled

up the inclined plane formed by the skids, and can be brought

directly over the trench. The arrangement is what seamen call

a common "parbuckle." It is often used in the city in

lowering heavy barrels into cellars.

Slings are then placed around the pipe now lying on the skids

over the aperture. Tackle is hooked on, and it is lifted a little

by the steam windlass, and the skids are withdrawn. It is then

lowered into the trench. This stage of operation is shown in the

cut. As it descends, the pipe layers guide it into position. Its

small or spigot end is entered into the hub or socket of the preceding

length, and it is blocked up in a horizontal position iii line

with the work. This ends this stage of operations.

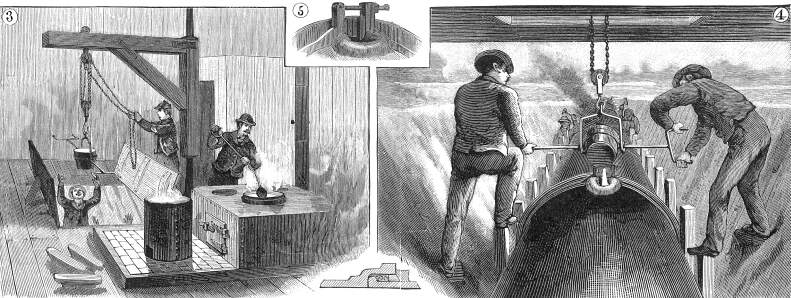

The joint has next to be calked with oakum. This is driven

by hand with a calking iron. It extends all around the pipe within

the hub, and is of as even thickness, as possible. It forms a

base for the lead, which latter is the actual joint-making material.

It should be noted that there is a slight space left between the

abutting ends of the pipe to allow for changes of temperature.

To complete the joint melted lead has to be introduced into

the space in front of the oakum and the lead in turn has to be

calked. As the apparatus just described is moved forward, the

lead-melting plant seen in its rear is moved into its place. This

consists of a house with furnace and lead pot, ladle, and crane.

Its interior is shown in Fig. 3, the men being engaged in lowering

a ladle full of melted lead. Next to the large furnace is a smaller

circular furnace. This is used to keep the ladle hot when it is

not in use.

The lead is lowered, as shown, into the trench, where it is

received by the pipemen and poured into the joint, as shown in

Fig. 4. Before doing this a band of iron hinged at the bottom

is placed around the pipe and bolted at the top, so as to inclose

the annular space in front of the oakum. A clay mouth or funnel,

Fig. 5, is arranged for the lead to be poured into. The connection

of two pipe ends, hub and socket, with their oakum and lead filling,

and with the band in place, is shown in the small sectional view

at the foot of the cut.

The lead at once solidifies. The band is removed, and the calkers

attack the lead with large-faced calking irons and hammers and

drive it home. This operation expands the lead and makes it fill

the joint perfectly.

The metal being somewhat yielding does not form too rigid a

connection, and allows for changes of temperature. In spite of

numerous attempts, lead-calked joints have never been displaced.

The trench in rear of the apparatus is filled in as fast as it

progresses, and the work is complete up to that point.

The object of the line is to carry water from the new reservoir

between Rockville Center and Baldwins, on the south side of Long

Island, to the Ridgewood reservoir and new pumping station at

East New York. It will be a pressure line, and will have a capacity

of twenty-five millions of gallons per day. It follows the line

of the old aqueduct for part of the way. The sectional view, Fig.

2, shows the aqueduct full of water on one side of it. The aqueduct

embankment is thus, in part, utilized in its construction.

Fig. 3—Interior of Lead Melting Plant

—— Fig. 4—Pouring a Joint —— Fig. 5—Arrangement

of Joint for Pouring

The work is being executed. by Mapes, Crawford & Valentine,

of Brooklyn, N. Y. They are the designers of the ingenious and

efficient apparatus whose results have taken the direction of

greatly accelerating the work we have described.

Stories Page | Contents Page

|