ANOTHER MAMMOTH LOCOMOTIVE.

Scientific American—December 3,

1898

The locomotive which we illustrate this week is unquestionably

the most powerful ever constructed. As we have shown elsewhere,

the continually increasing size of American engines is due to

the desire to secure the most economical results in operation.

As between the policy of hauling a heavy train with a single engine

or two light trains with light engines, there is, in the former

case, a saving of the expense of a complete train crew. Further

advantages, at least on tracks where the traffic is heavy, result

from the reduction of the number of separate trains in operation.

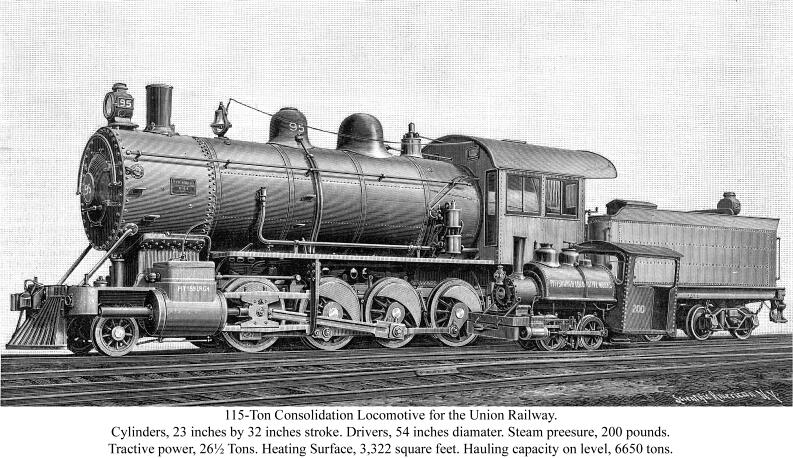

The two locomotives of the type shown have recently been built

by the Pittsburg Locomotive and Car Works for the Union Railroad

Company, Pittsburg. They are at work on a short stretch of line

between Munhall and North Bessemer, Pa., which forms part of the

Carnegie system and connects the Duquesne Furnaces, Homestead

Steel Works and the Edgar Thomson Steel Works. Four miles of the

line are built on a grade of 70 feet to the mile and another stretch

of the road (about 2,000 feet) is built on the unusually heavy

grade of 2.7 per cent.

We are informed by Mr. D. A. Wightman, the general manager

of the Pittsburg Locomotive and Car Works, to whom we are indebted

for the photographs from which our engravings were prepared, that,

owing to the great amount of wet weather since these locomotives

went into service, the company have been unable to secure any

reliable data of their performance in actual service on the various

grades of the road.

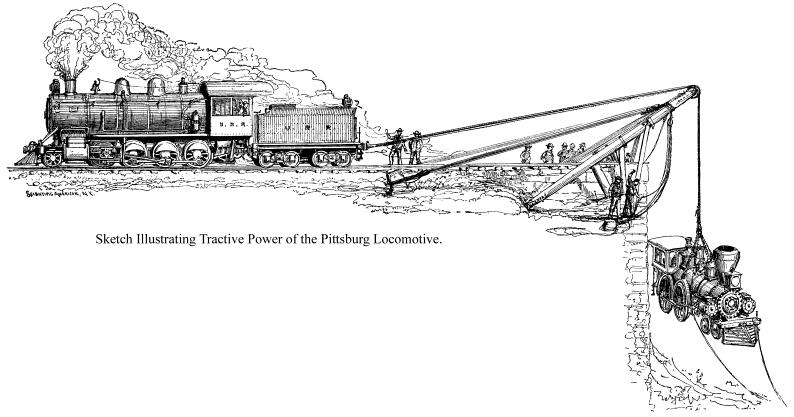

The estimated tractive force, however, is 53,280 pounds and

the estimated hauling capacity on a practically level track is

about 6,650 tons. Now, just what these figures mean can perhaps

be best understood by expressing them in other terms. The accompanying

sketch, which is, of course, purely imaginary, shows what an engine

with a drawbar pull of 26½ tons could accomplish in the

way of lifting dead weight. The locomotive slung in chains represents

a passenger engine of the average size used in this country thirty

to forty years ago. If a cable were passed from the slings over

a pulley and carried to the drawhead of the tender of one of these

Pittsburg consolidations, she would be able to raise the smaller

locomotive by direct pull without the use of any kind of purchase.

The hauling capacity on a level of 6,650 tons represents a

train of 166 box cars loaded with wheat. The total length of such

a train would be 5,700 feet, or considerably over a mile, and

the wheat would represent, at an average of 15 bushels to the

acre, the product of 9,000 acres, or over 14 square miles of land.

And this enormous load could be taken over the road, or rather

the level portions of it, at a comfortable speed of 10 miles an

hour.

He would have seemed a bold prophet to our forefathers who

would have dared to foretell that at the close of this century

we should have steam horses that could cart away the products

of 14 square miles of the countryside at a load, and do it at

a gait faster than that of the local mail coach.

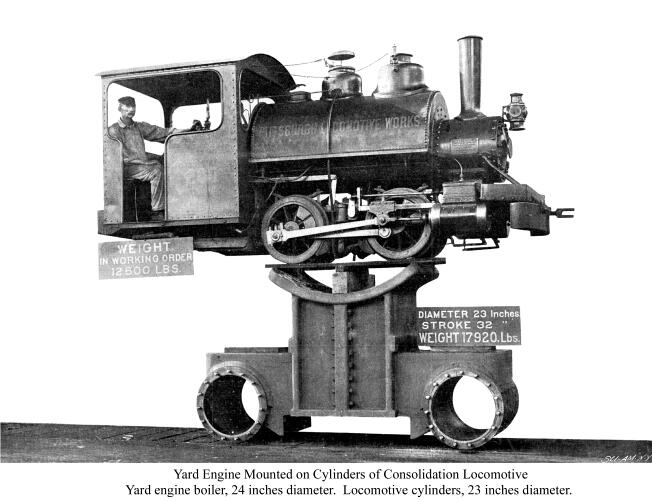

The very remarkable photograph which is reproduced on the front

page serves excellently well the purpose for which it was taken,

namely, to give an impressive idea of the great size of the parts

of the locomotive. The little engine was lifted to its perch by

the shop crane. It is standing on the cylinder casting, which

weighs 8¾ tons, as against a weight of 6¼ tons for

the yard engine. The other particulars of the yard engine are:

Cylinders, 6 by 10 inches; gage, 24 inches; diameter of boiler,

24 inches; driving wheels, 26½ inches; tractive force,

1,883 pounds.

It will thus

be seen that the cylinders of the big engine, which are 23 inches

in diameter, are only 1 inch less than the diameter of the yard

engine boiler. It will thus

be seen that the cylinders of the big engine, which are 23 inches

in diameter, are only 1 inch less than the diameter of the yard

engine boiler.

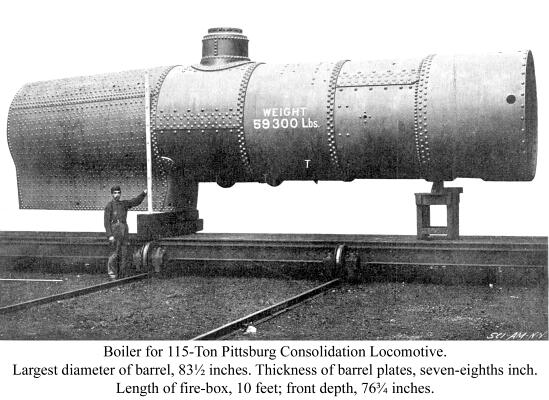

The cylinders of the consolidation are of the half-saddle type,

made heavy, and have great depth longitudinally. A steel plate

1-and-three-eighths inches thick, and of the same width as the

bottom of the saddle, extends across and is bolted to the lower

frames, and to this plate, as well as to the frames, the cylinders

are securely fastened. Heavy bolts passing through the top frame

bars at the front and back of the saddle form additional transverse

ties, and relieve the saddle casting from all tensile strains.

The longitudinal strains usually transmitted to cylinders through

frames are largely absorbed by the use of a casting extended from

the buffer beam well up to the saddle, and securely bolted to

the top and bottom frames. This casting also acts as a guide for

the bolster pin of the truck. The above method of relieving cylinders

of longitudinal stress was introduced by the Pittsburg Locomotive

Works nearly two years ago and has proved in practical use on

a large number of locomotives to be of great value in reducing

the breakage of saddle castings. The frames are 4½ inches

wide. They were cut front rolled steel slabs made by the Carnegie

Steel Company and weigh 8½ tons per pair, finished.

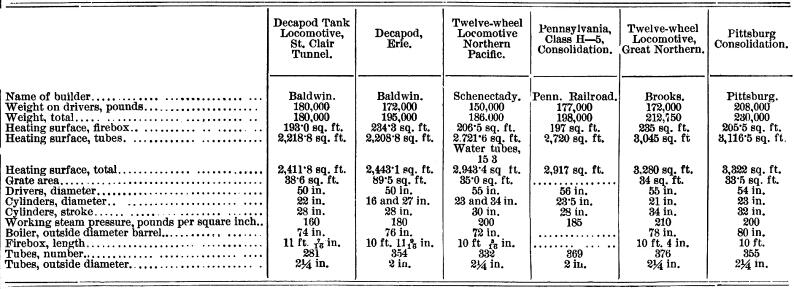

In the accompanying table we give a comparison of some of the

most notable of the recent big freight locomotives, from which

it will be seen that the latest is considerably the largest of

the big fellows. They are arranged in the order of their construction.

The tender is of the standard type and weighs, loaded, 52 tons,

so that the weight of the engine and tender in working order is

167 tons. The total length over all of engine and tender is 63

feet 3½ inches. The center of the boiler is 9 feet 3-and-three-eighths

inches above the rails, the top of the boiler is 13 feet and the

smokestack 15½ feet above the rails. The driving axle journals

are 9 by 12 inches, and the main crank-pin is 7 by 7 inches. The

steam ports are 1-and-three-eighths inches wide by 20 inches long,

while the exhaust ports are 3¼ inches by 20 inches. The

tender has a capacity of 5,000 gallons of water and 10 tons of

coal.

Stories Page | Contents Page

|