SPEED IN LOCOMOTIVES.

Scribner's—January to June, 1892

THE LIMITATIONS OF FAST RUNNING.

By M. N. Forney.—Editor, Railroad and Engineering

Journal

RACING seems to be a natural instinct in human beings as well

as in other animals. In our natures this instinct seems to be

stimulated, and not satisfied, by the means which science has

supplied for achieving rapid movement, and modern appliances are

now put into requisition for the gratification of this natural

bent. Whole nations are now interested in the "records"

of transatlantic steamers, and in the time made by the Flying

Dutchman or the Columbian Express. Each gain in speed, in both

land and water, seems to add to the eagerness with which people

inquire about future possibilities.

When Stephenson's Rocket, on its trial trip, made a speed of

nearly thirty miles an hour, doubtless those who saw and heard

of it were as anxious then to know how much faster a locomotive

could run as we are to-day when we travel more than twice as fast.

In speculating on this subject a sort of single-rule-of-three

logic is sometimes applied to it which is apt to lead to erroneous

conclusions. Mechanical dialecticians assume as a premise that

the improvements which have been made in locomotives in sixty

years have resulted in doubling the speed, therefore in sixty

years more we will be able to travel twice as fast as we do now.

Or, in other words, sixty years ago we travelled 30 miles an hour

and now we travel 60, therefore as 30 : 60 :: 60 :120= the speed

at which we will travel sixty years hence. There are, however,

greater difficulties in the way of doing this than appear from

this arithmetical syllogism. The aim of this brief discourse on

railroad speed will be, to use words of Mr. Carlyle which referred

to quite a different subject, "to tell practically, in reasonable

words, what the possibilities, limitations, difficulties, laws,

and conditions of the enterprise are."

It may be said, in the first place, that to move an ordinary

car on a level railroad track requires the exertion of a horizontal

pull of from four to five pounds for each ton (of 2,000 pounds)

of its weight. That is, if it weighs twenty-five tons and a rope

is attached to it, it will be necessary to exert a pull of from

one hundred to one hundred and twenty-five pounds on the rope

to keep the car moving at a slow speed after it is started. As

the speed increases, the "resistance"—as it is

called—of the car also increases: that is, more force or

pull must be exerted to keep it moving. The exact rate with which

this resistance is augmented when the speed is accelerated, and

the laws governing it, are still imperfectly understood. Our knowledge

of the subject—especially that relating to the higher speeds—is

only approximate, and probably not a very close approximation

either. Tables have been compiled—from such data as are available—showing

the resistance of trains at different speeds. The accompanying

diagram is constructed from such a table, in which the resistances

have been plotted, so as to show graphically the rate at which

they increase. The speed in miles per hour is laid off on the

base line 0-100, each space between the vertical lines representing

five miles per hour. The spaces between the horizontal lines represent

the resistance in pounds per ton. The resistance per ton for the

speed represented by each vertical line is laid off from the base

line, and a curve, A B C, is drawn through the points thus

laid down. Its vertical distance, as 40 B above the base

line, at any point 40, thus represents the resistance at the speed

indicated by that point. At sixty miles an hour, it will be seen

the curve shows that the resistance is twenty-five pounds per

ton.

No data exist

to show how much power is required to pull a train at a speed

greater than seventy miles per hour; but if the curve in the diagram

is continued beyond the vertical line representing seventy miles

per hour, as shown by the dotted line C D, it will indicate

approximately the rapid rate at which the resistance probably

increases above that speed. No data exist

to show how much power is required to pull a train at a speed

greater than seventy miles per hour; but if the curve in the diagram

is continued beyond the vertical line representing seventy miles

per hour, as shown by the dotted line C D, it will indicate

approximately the rapid rate at which the resistance probably

increases above that speed.

It must be remembered that to maintain a high rate of speed

there must be a continuous pull exerted on the drawbar of a locomotive,

and that the relative amount of this pull at different speeds

is indicated by our diagram.

This propelling power of a locomotive is due to the pressure

which is exerted on the pistons of two cylinders by the expansive

action of the steam. Each piston makes two strokes, or moves twice

through the whole length of the cylinder during each revolution

of the driving-wheels.

It will be assumed that we have a locomotive with driving-wheels

six feet, and cylinders eighteen inches, in diameter, and pistons

which have two feet stroke. Such an engine with its tender would

weigh about ninety tons. Each cylinder would have a capacity of

about three and a half cubic feet. Excepting in starting a train,

these cylinders are filled only partly full of steam from the

boiler, for two reasons—first, because it would be a very

wasteful use of steam to fill them entirely full, and second,

it would be impossible for the boiler to supply enough to fill

them when running fast. Therefore steam is "cut-off,"

as it is termed—that is, it is admitted to the cylinder during

a third or a fourth or some other fraction of the stroke, and

the opening which admits it to the cylinder is then closed, and

the steam which has been admitted is allowed to expand while the

piston is moving to the end of its stroke.

To show how the speed and load of a locomotive are limited

by the supply of steam, it will be supposed that for each stroke

of the pistons the cylinders are filled one-third full of steam

of the boiler pressure of one hundred and sixty pounds. This is

expanded in the cylinder during the completion of the stroke of

the pistons. For each revolution of the wheels, therefore, four-thirds

of a cylinder full of steam would be used. Wheels six feet in

diameter would turn 280 times in running a mile, and at 60 miles

an hour they would turn 16,800 times in that period, and would

consume 79,161 cubic feet of steam. On making comparisons of the

quantities of steam of varying pressures used, it is best to do

it in terms of its weight, because that will represent the actual

quantity irrespective of its pressure or volume; 79,161 cubic

feet of steam of 160 pounds pressure per square inch will weigh

31,094 pounds.

It has been found that the greatest amount of coal which can

be burned in an hour, on each square foot of grate of a locomotive,

is about two hundred pounds. A locomotive such as we have described

would have about twenty-four square feet of grate area, so that

4,800 pounds of coal is the maximum amount which could be burned

in its fire-box per hour. At this high rate of combustion each

pound of fuel would not evaporate more than about six pounds of

water, and, therefore, not more than 28,800 pounds of water could

be evaporated in such a boiler per hour. This, it will be seen,

would not be sufficient to supply the cylinders under the conditions

of working described. Consequently, in running an engine at 60

miles an hour we would be obliged to reduce the quantity of steam

admitted to the cylinders, which would either diminish the load

which could be hauled or the speed of running. If instead of cutting

off the steam at 8 inches and filling the cylinders one-third

full of steam during each stroke, it was cut off at 7 inches,

the consumption per hour would be reduced to 27,207 pounds, which

is somewhat less than the maximum quantity which it is possible

for the boiler to supply. Not counting any back pressure or any

other losses or waste, the maximum tractive or pulling force which

this quantity of steam would exert would be equal to 10,700 pounds.

As the resistance at this speed, as shown by the diagram, is 25

pounds per ton, the maximum load which could be hauled would be

428 tons, including the weight of the engine and tender, or 338

tons without. Practically, an ordinary locomotive would not do

nearly as much work as this, on account of the back pressure in

the pistons, waste, friction of the machine, and losses of various

kinds in the engine.

If the speed were increased to 90 miles an hour, then the number

of strokes made by the pistons would also be increased in like

proportion. The capacity of the boiler to generate steam would,

however, be no greater at this high velocity than it was at 60

miles an hour. Therefore, instead of cutting off the steam at

7 inches of the stroke, we would be obliged to cut it off at about

5 inches. The tractive force exerted by this steam could not be

more than 8,494 pounds. The resistance of the train would, however,

according to our diagram, be about 51 pounds per ton. The maximum

load which could be hauled would therefore not exceed 166 tons,

including the weight of engine and tender, or 76 tons without.

In practice this could not be done with an ordinary engine, on

account of the losses and waste of various kinds already referred

to.

These calculations therefore indicate that at a speed of

100 miles per hour on a level track, an ordinary locomotive would

do tittle more than pull itself and its tender, and maintain the

speed for any considerable time. Of course, on an ascending

grade it could not do this.

Before considering the possibilities of the future, some of

the other obstacles in the way of making very fast time must be

referred to.

If the driving-wheels of a locomotive are three feet in diameter,

their circumference will be nearly nine and a half feet long,

and in travelling a mile, or 5,280 feet, they must turn 560 times.

A speed of thirty miles an hour is equal to one mile in two minutes,

so that, at that velocity, wheels three feet in diameter must

be turned 280 times per minute. We may double this speed by turning

the wheels twice as often in a given time, or by making them twice

as large, or six feet in diameter, and turn them the same number

of revolutions in any given period. To quadruple the speed—that

is, to run 120 miles per hour—wheels three feet in diameter

would have to turn 1,120 times per minute, or if they revolve

only 280 times, they must be 12 feet in diameter to make that

speed. Big driving-wheels in a locomotive always excite popular

admiration; but in designing a locomotive an engineer cannot allow

his imagination to guide him. He is absolutely confined to certain

limits, such as the weight which can be carried on each wheel,

the space between the rails, or the "gauge" of the track,

as it is called, the length of the wheel-base which will permit

the engine to run around curves, the height of tunnels overhead,

bridges, etc.

As a practical illustration of this, we may take the limitations

which would be imposed on a designer of an express locomotive

of the heaviest and most powerful type now used. The maximum which

is now allowed in this country on each driving-wheel is 20,000

pounds. More than this would be considered injurious to both the

rails and wheel-tires, and would be likely to cause the axles

to heat, owing to the excessive friction due to the weight on

the journals. The whole length of the wheel base must not exceed

24 or 25 feet, and if a truck is placed in the usual position

under the front end of the engine, it will carry about a third

of the weight of the engine, or one-half as much as the four driving-wheels.

The total weight of such a locomotive, without its tender, will

therefore be as follows:

20,000 pounds on each of four driving-wheels 80,000

10,000 pounds on each of four truck-wheels 40,000

Total . . . . . . . . . . . . . . . . . . . . . . .120, 000

A still more powerful locomotive could be constructed if we

used six driving-wheels, but for the present only the eight wheeled

engine will be considered.

The problem the designer, then, has to solve is to proportion

the parts of his locomotive so as to produce the most efficient

machine of that weight. During each revolution of the wheels the

pistons must be moved backward and forward through their whole

stroke. At 70 miles an hour a six-foot wheel of a locomotive would

revolve more than five times in a second. During every revolution

each piston and its connection must start and stop twice. They

come to a state of rest at the end of each stroke, and must be

started and their motion accelerated to a speed of nearly 35 feet

per second, in less than one-tenth of a second, and then come

to a state of rest again in the same time. When it is remembered

that each of the pistons, with their moving connections, weighs

considerably over 500 pounds, the amount of power required to

move them, and the disturbing effect which they exert on being

started and stopped twice during each revolution at these high

speeds may be imagined. To neutralize these disturbing effects

balance-weights are placed in the wheels opposite the cranks.

These accomplish their purpose, however, only partially, for the

reason that they move in a circle, while the piston and other

reciprocating parts have only a horizontal motion. Consequently,

while the balance-weights may be made to neutralize the horizontal

motion and momentum of the pistons, etc., the weights themselves

thus produce a vertical disturbing force which at high speeds

has been said to be so great as to bend the rails on which the

locomotives are running. For these reasons a compromise is usually

made by balancing the reciprocating parts only partially, which

lessens the vertical disturbance but does not entirely compensate

for the horizontal momentum of the reciprocating parts. Therefore,

a locomotive at best is an unstable machine at high speeds.

The obvious expedient for getting over this difficulty is to

increase the size of the wheels of fast engines, and it seems

like a very simple inference to assume that, if a locomotive with

wheels 3 feet in diameter will run satisfactorily at speeds of

30 miles per hour, therefore, to run at 60 miles an hour all we

need do is to increase the wheels to 6 feet, and then with the

same number of revolutions we shall make double the speed, and,

with wheels 7½ feet in diameter we can run 75 miles an

hour as easily as we can travel 30 miles with 3-foot wheels. But

in enlarging the size of wheels we soon reach limitations, owing

to their increase in weight and in that of other parts. The weight

of a wheel increases about as the square of its diameter. If its

diameter is enlarged, the size of the cylinders and their connections

must all be larger and heavier. This makes necessary stronger

frames and an increase in size and weight of many of the other

parts. Now, the importance of having ample boiler capacity has

been explained. If, then, the weight of our hypothetical locomotive

is limited to 120,000 pounds, every extra pound of weight which

is put into the wheels, cylinders, frames, etc., means that the

weight of the boiler must be that much less. In other words,

the bigger the wheels are, the tighter and smaller must be the

boiler. The problem which the locomotive designer, then, has

to consider and determine, is the sum of the advantages which

will result from an increase in the size of the wheels, and a

diminution of that of the boiler, or vice versa.

It may be said that no common agreement with reference to the

size of locomotive wheels has ever been reached by locomotive

engineers. Practice seems to vacillate: at one time wheels as

large as 10, and we believe 12, feet in diameter were employed,

but these excessively large sizes have now been abandoned. At

present American practice seems to incline toward larger sizes.

In running the Empire Express on the New York Central road, engines

with wheels 6 feet, and others of 6 feet 6 inches diameter have

both been used, with the result that the service of the engines

with the larger wheels has been decidedly the most satisfactory.

As an essential thing to do in running fast is to turn the

wheels rapidly, it might be thought advisable to increase the

power available for this purpose by enlarging the cylinders. Here,

too, we encounter a difficulty. If the cylinders are larger than

a certain size, the force which will be exerted by a given steam

pressure to turn the wheels will be greater than their "adhesion"

or friction on the rails, and they will slip, and we shall have

what engineers call a "slippery engine." The cylinders,

driving-wheels, the weight on them, and the steam pressure must,

therefore, bear such proportions to each other that the pistons

can exert what is called a "rotative effect" on the

wheels equal to, but not much in excess of, their adhesion or

friction on the rails.

Another obstacle in the way of running at high speeds is that

of getting the steam into the cylinders, and have it exert the

requisite pressure on the pistons, and then get it out again,

so that there will not be any, or as little, back pressure as

possible in front of the pistons. The quickness with which the

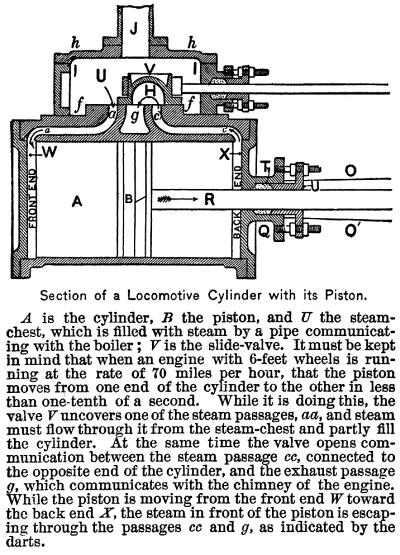

steam must act may be understood from the figure on next-page,

which represents a section of a locomotive cylinder with its piston.

As already remarked, at 70 miles per hour this action must begin

and be completed in less than a tenth of a second. What adds to

the difficulty is the fact that, in order to stimulate the fire,

the opening in the ends of the exhaust-pipes through which the

steam escapes must be more or less contracted, so as to produce

a blast in the chimney to stimulate the fire. This, of course,

obstructs the free flow of the escaping steam from the cylinders,

and produces more or less back-pressure on the pistons.

The mechanism for admitting the steam to, and exhausting it

from, the cylinders, performs a very important part in fast-running

engines, as the action of the steam in the cylinders depends very

much on that of the slide-valves, and no problem connected  with locomotive construction

has been the subject of so much thought and invention as that

of "valve-gear," or the mechanism for working the valves.

It has been analyzed mathematically, elucidated graphically, demonstrated

mechanically, and tested experimentally in every conceivable way.

Numberless inventions have been made of mechanism for this purpose,

but what is called Stephenson's "link motion," which

was adopted by him, although he was not its inventor, still holds

its supremacy among valve-gears, and there are at present no signs

that it will soon lose it. with locomotive construction

has been the subject of so much thought and invention as that

of "valve-gear," or the mechanism for working the valves.

It has been analyzed mathematically, elucidated graphically, demonstrated

mechanically, and tested experimentally in every conceivable way.

Numberless inventions have been made of mechanism for this purpose,

but what is called Stephenson's "link motion," which

was adopted by him, although he was not its inventor, still holds

its supremacy among valve-gears, and there are at present no signs

that it will soon lose it.

There is much less difficulty, however, in getting the steam

into the cylinders than there is in getting it out, because there

is a pressure in the boiler of from 150 pounds to 200 pounds per

square inch to force it in; but after it has done its work in

the cylinders it has been expanded and its pressure and temperature

very much reduced, so that it is partially condensed or liquefied,

and consequently does not move with as much celerity as "live"

steam, as it is called, fresh from the boiler does. The result

is that at high speeds there is always an increase of back pressure

in front of the pistons, which has a retarding effect, at the

time when it is essential that the maximum power should be exerted

by the pistons. If the engineer tries to compensate for this by

admitting more steam in front of the pistons, then the demand

on the boiler becomes so great that it cannot supply it. Besides

this, the escaping steam then has not had sufficient opportunity

to expand, and escapes up the chimney with such violence as to

"tear the fire to pieces," as firemen express it. An

engineer who is running an engine must therefore be careful, at

high speeds, not to use more steam in an engine than the boiler

can supply, and generally the limitations to speed in a locomotive

are the same as those of a horse—want of wind.

A writer on this subject has formulated the maxim, that "within

the limits of weight and space to which a locomotive boiler is

necessarily confined it cannot be too big." Certainly the

larger it is the greater will be the efficiency of the engine,

and the more economical will it be in the use of fuel.

The limitations in the weight of a locomotive have been explained.

Its size is necessarily confined by the distance between the rails,

or their "gauge," as it is called. This on ordinary

roads is 4 feet 8½ inches. The flanges of the wheels are

inside of the rails, so that the distance between the tires is

4 feet 5-and-three-eighths inches. The frames of the engine are

ordinarily inside of the tires and the fire-box inside of them.

Therefore, as usually constructed, it can be only about 3 feet

7 or 8 inches wide. The result is that this part of the boiler

is contracted in one of its vital parts, and it has been remarked

that the back end of a large locomotive boiler looks like a broad-shouldered

woman in tightly-laced corsets. Under these conditions the vital

parts of both the woman and the locomotive are contracted. To

partly obviate this difficulty in locomotives, their fire-boxes

are now often placed on top of the frames. This allows them to

be about 8 inches wider than they could be if they were between

the frames, but the height of the firebox must then be reduced.

In the Wootten locomotive—named after its inventor—the

fire-box is located entirely above the wheels, and can then be

made as wide as the widest part of the locomotive. This necessarily

raises the centre of gravity of the boiler and reduces the depth

of the fire-box.

From what has been said it will be seen what an exceedingly

difficult problem is presented to a locomotive engineer in designing

an engine for very high speeds. It is largely a matter of relativity

and proportion. A maximum speed can be attained only when the

different organs, as—they may be called, hear the proper

proportion to each other, and the ability of the designer is shown

by his recognition of the relative value and importance of the

proportions of the different parts.

The question whether we shall ever be able to travel on railroads

at a regular speed of 100 miles per hour is often asked. Most

railroad managers are disposed to answer the question as David

Copperfield replied to the disparaging remark about the inability

to swing a cat in his room. He replied that he didn't want to

swing a cat, and so most managers say they don't want to travel

at the rate of 100 miles per hour. Those who know most about the

risks of such speeds seem least inclined to encounter them. Every

school-boy knows that after a kite has reached a certain height,

no amount of added string will allow it to fly higher. The span

of a bridge may be so long that it will not carry its own weight.

So our diagram of train resistance shows that when we get above

70 miles per hour, the resistance of the locomotive and that of

the cars becomes so great that it will do no more than pull itself

and its tender. When this point is reached, further increase of

speed becomes impossible with the locomotives we are now using.

Besides the difficulties which have been pointed out, there

is the risk, at high speed, of the breakage of the coupling-rods—by

which the cranks on adjoining wheels are coupled together—owing

to the strain to which they are subjected by centrifugal force.

This danger increases with the distance apart of the wheels and

the length of the rods, and the centrifugal force which acts on

the rods increases with the number of revolutions of the wheels;

and consequently, as large wheels make fewer revolutions at a

given speed of train, the centrifugal force exerted on the rods

is then inversely to the diameter of the wheels, or, in other

words, the larger they are the less is this force.

With high speeds and the heavy express engines which are now

used, a good deal of trouble is also experienced from the heating

of the journal bearings of the driving-axles, owing to insufficient

bearing surfaces. Their size is limited when the fire-boxes are

placed between the frames, because in order to make the former

as wide as possible, the frames are placed as far apart as the

wheels will permit. This shortens the journals, and consequently

diminished the surface of their bearings. The cure for this is

to bring the frames nearer together and thus lengthen the journals.

There is no objection to doing this when the fire-boxes are not

between the frames.

It may therefore be inferred that there is not much probability

of attaining regular and continuous speeds of 100 miles per hour

with our present locomotives. Their fire-boxes—which perform

the same functions for the machines that their stomachs do for

animals—are, with the present system of construction, necessarily

contracted in size. The weight of the whole locomotive being fixed,

the dimensions of the different parts are also limited.

It is proverbially dangerous to prophesy when you are not quite

sure, and if prognostications are based upon calculations the

mendacity of figures may rise up hereafter to deprive the prophet

of all honor.

From what has been said, however, it will be seen that fast

running is largely a question of steam production. Given a

boiler which will generate enough steam, and the other problems

are of comparatively easy solution. The difficulty is to get the

boiler sufficiently large within the limits of size and weight

to which it must be confined.

It will be safe to say that to be able to travel continuously

at 100 miles per hour we must have either boilers or fuel which

will generate more steam in a given time than those we are using

now do, or our engines must use less steam to do the same work,

or, what is more probable still, we must have all three of these

features combined. In the locomotive of the future the action

of the reciprocating parts will probably be more perfectly balanced

than it now is; coupling-rods will either be dispensed with altogether

or their risk of breakage will be lessened by placing the driving-wheels

near together, and both this danger and the disturbing effect

of the reciprocating parts will be lessened by increasing the

size of the wheels. To enable the engine, or, rather, its journals,

to "run cool," the journals and their bearings will

be increased in size so as to have ample surface to resist wear.

Just how these improvements will be made, it is perhaps too

early to predict. Coming events are, however, already casting

their shadows before them, and there are indications that the

improvements which are here foreshadowed, or some of them, are

in process of evolution. In Mr. Webb's new engine, Greater Britain,

recently built for the London & Northwestern Railway, the

boiler has been materially increased in size, and he reports the

remarkable performance of evaporating nearly eleven pounds of

water per pound of coal while pulling a heavy train at the rate

of over 44½ miles per hour. This engine is compounded so

as to use steam with the greatest economy, and is without coupling-rods.

These are dispensed with by using three cylinders—two high

pressure and one low pressure. The two former are connected to

the back pair of driving-wheels and the latter to the front pair.

By this means both pairs of wheels are driven by separate cylinders.

A new express locomotive is now in process of construction in

this country with a fire-box about twice as wide as those ordinarily

used. The problem of improving the balancing of engines is attracting

much attention, and the bearing surfaces of many recent locomotives

have been materially increased. Driving-wheels have been enlarged

in size with the increase in speed, and if the march of improvement

continues—and there is no reason for thinking it will not—the

anticipation that we shall travel at the rate of 100 miles per

hour may be fulfilled while some of us are left here to see it.

TRAIN-SPEED A QUESTION OF TRANSPORTATION.

By Theodore N. Ely.—General Superintendent of

Motive Power

—Pennsylvania Railroad

IT is a pleasing sign of the times to witness the growing interest

taken by the general public in railway matters. This demand has

caused the daily press and magazines to give considerable space

to a presentation of such of the problems as can well be treated

by them. As a supplement to the more detailed and technical discussions

of the scientific journals, the opinions of the press will be

welcome to all professional railway officers; and without doubt

will go far toward securing high standards of management. Much

has been written relating to speed of trains, the different phases

of which have been so well explained that anything to be said

at this time must in a measure go over oft-trodden ground.

But what is a fast train? The very difficulty in giving a proper

definition here helps to prove that speed is a relative term.

"Will you walk a little faster?" said a

whiting to a snail,

"There's a porpoise close behind us, and he's treading on

my tail."

This couplet suggests to me, as it probably did not to its

author, a perfect description of a slow-moving train—even

to the necessity for, and evident absence of, the Block System!

But it is not so easy to say what speed entitles a train to the

distinction of being called fast.

It can hardly be said that the possible speed of locomotives

has improved in the last fifteen or twenty years. The records

would no doubt show that the locomotives of that period made,

on occasions, as fast runs with trains within their capacity as

those of the present day. It is indeed reassuring when we recall

the high-speed journeys taken safely over the tracks and alignment

which existed twenty-five years ago. We were either very brave

or very ignorant in those days; for, from our present point of

view, we would regard the running of trains at such speed over

such tracks as extremely hazardous. There were accidents, to be

sure, but not of such frequency as the railroad engineer of today

would predict.

Briefly, the radical improvements which have been accomplished

may be comprised under three general heads—Roadway, Equipment,

and Signals.

ROADWAY.—Some twenty-five years ago the Pennsylvania

Railroad adopted broken stone as best meeting the conditions of

a good track foundation; at the same time the dimensions and number

of ties were fixed, and finally the rails and turnouts were laid

according to carefully considered rules. The weight of rails has

been increased, with a corresponding improvement in fastenings;

the old turnouts have given place to those of more modern design;

but the foundation is much the same as that first adopted. Closely

related to the roadway are crossings at grade. These have, from

time to time, been abolished as detrimental to the safe passage

of trains.

EQUIPMENT.—In equipment, the locomotive has been

thoroughly redesigned and made stronger in all its parts. The

air-brake applied to its driving and tender wheels, has made it

possible not only to stop itself quickly, but assist in retarding

the train, as well. The strength of passenger cars has been increased,

until they have reached a weight of 27 tons, and the couplings

and platforms have been greatly improved. Sleeping-car construction

has likewise advanced, until the more modern ones have reached

a weight of nigh 50 tons. The air-brake has become indispensable

as a condition of safety in fast-moving trains.

SIGNALS.—In the early days of railways there was

nothing that could properly be dignified by the name of signal.

By slow degrees, as is usual in matters involving questions of

safety, a high state of development has at last been reached.

The best systems of signalling and interlocking are marvels of

mechanical skill and ingenuity, and command the respect due to

their wonderful reliability.

The pirate of the Mediterranean would be flattered, indeed,

if he could know that the semaphore signal of warning he was wont

to display from the rock of Gibraltar had become the recognized

danger signal of modern railways.

It may be interesting to note in passing, a few instances of

train movements which have come under the writer's observation.

Nearly sixteen years ago, or to be exact, in June, 1876, a Pennsylvania

Railroad standard locomotive drawing a train of two sleeping-cars

and a dining-car, covered the distance between Jersey City and

Pittsburgh, 438.5 miles, without a stop, in 605 minutes, or an

average rate of 43½ miles an hour. This journey is interesting

as the longest known continuous run; and one which involved thorough

transportation arrangements for its movement, and great endurance

on the part of the locomotive. The special train was en route

to San Francisco, which city was reached in 84 hours and 17

minutes after leaving New York.

The train which conveyed our lamented President Garfield from

Washington to Elberon, September 7, 1881, was run under conditions

of great excitement and anxiety. His life hung upon a thread,

and any detention to the train would have resulted disastrously.

The heat was intense and prostration was imminent. The physicians

had fixed upon 30 miles an hour as the speed which would give

the least discomfort to the patient. After the train was well

under way, and without warning, an increase in speed was determined

upon, which reached 65 miles an hour before the journey was completed.

The orders for the transportation of this train were contained

in one message, and so skillfully was it worded that, despite

the changed conditions, there was not the slightest detention

from any cause.

A most noteworthy accomplishment was that of the Pennsylvania

locomotive which drew the special train of the delegates to the

International American Conference on their tour to the principal

cities east of the Rocky Mountains. This engine traversed the

rails of twenty distinct lines of railroad, and covered 10,000

miles in its course, without accident of any kind or unreasonable

delay.

Another example of endurance may be mentioned—the 126,000

miles made by one locomotive between Philadelphia and Washington

in the year 1891—equal to five complete journeys around the

world.

From the lessons of the past we may forecast the future, for

certainly we have reached that stage in railway progress where

we may assert with confidence that our acts and opinions are based

upon accumulated experience and not upon prophetic inspiration.

Guided by this light, let us consider what factor will control

the limit of speed in the passenger-trains of the future.

In the road-bed we shall have to demand that the alignment

be almost free from curvature, and the width between the tracks

be increased; that the foundation shall be stable and well-protected

from rain and frost; that land-slides and other accidental obstructions

shall be provided for; that the ties shall be firmly embedded;

that the rails shall be heavy—one hundred pounds, or more,

if necessary—and securely fastened; that all frogs and switches

shall be proof against accidental misplacement or rupture; that

all drawbridges shall be made secure beyond question, and, finally,

that all crossings at grade be abolished. We must further insist

that a thorough system of supervision and inspection shall be

carried out.

With a fulfillment of these conditions, which, professionally

speaking, are perfectly practicable, trains, so far as the road-bed

is concerned, may be run in safety as fast as any locomotive can

be made to haul them.

Of the locomotive, it may be said that, only with the improvements

in road-bed referred to, can its highest attainable speed be utilized.

The measure of the speed and capacity of the locomotive rests

in the fire-box, the length and breadth of which cannot exceed

certain dimensions. It therefore follows that when this furnace

is arranged to burn the maximum quantity of fuel, the steam-producing

limit will be reached, and with it the limit of speed. But this

steam must be used to the very best advantage, as relating to

the proportions of the locomotive, as well as to its type; the

first of these are already well known, and it will probably be

found that some form of compounding will suggest the type. With

these limitations the speed of locomotives with passenger trains

will not fall far short of 100 miles an hour; by which is meant

a sustained speed at that rate, as, for instance, a trip between

New York and Philadelphia in about one hour, or between New York

and Chicago in ten or eleven hours.

As to car equipment, it is probable that, with some change

in size and proportions of wheels, journals, and other parts of

the trucks, the best class of cars in present use would be suitable

for the highest speed. They should be made to run as noiselessly

as possible, that the occupants may be relieved from any feeling

of insecurity or nervous strain. The air-brake should be applied

in its best form to both locomotive and cars, so that every pound

of braking weight would become instantly available.

The above conditions have been cited in detail to show that

they all must be fulfilled in order to make possible our future

travelling at the rate of 100 miles an hour. Make possible, yes,

but only upon the fulfillment of one other condition, namely,

a clear track ahead; and this it is which brings us to the real

measure of speed, which is the question of transportation in its

strict sense. This limit will vary with the number of trains already

on the line and with the facilities for handling them. First of

all, we must know how soon after receiving warning of danger a

train, running a mile in 36 seconds, can be stopped. It is estimated

that if running at 60 miles per hour, with the full braking weight

of the train utilized, and the rails in the most favorable condition,

this train could be brought to a full stop in 900 feet; at 80

miles per hour, in 1,600 feet; at 90 miles per hour, in 2,025

feet, and, finally, at 100 miles per hour, in 2,500 feet. These

figures at once establish the fact that under the best possible

conditions the track must be kept clear of all obstruction for

at least 2,500 feet in advance of a train running at the highest

limit; but we must estimate the clearance for the worst conditions,

such as slippery rails, foggy weather, and unfavorable grades;

the personal equation of the engineman must also be considered

in a train covering 145 feet each second.

Would it, therefore, be too much to ask that the engineman

receive his warning at least three-quarters of a mile before he

must halt ?

The difficulties of arranging for the passage of trains of

this character are manifest; we are not speaking of special trains,

but rather of regular trains, running as frequently as may be

desired. It should be remembered that, in a two-hour run, the

fastest trains of to-day would require a leeway of an hour, and

slower ones would have to start proportionately earlier, or be

passed on the way.

The most improved forms of signalling and interlocking, be

they mechanical, pneumatic, electric, automatic, or otherwise,

which are so necessary to the safe movement of passenger trains,

may be introduced, but cannot be placed nearer together than three-quarters

of a mile. The very presence of these signals, while giving the

maximum safety, has in practice made prompt movement more difficult.

They are governed by fixed laws, which, if obeyed, make chance-taking

impossible, for trains must keep a prescribed distance apart,

and increase in speed involves greater intervals. This state of

affairs would point to the necessity for an increase in the number

of tracks, so that passenger trains could be grouped on the basis

of speed just as it has been found necessary already, on crowded

lines, to separate the freight traffic from the passenger.

If this be done, and unlimited track facilities are furnished,

the prompt despatching of trains would not be the ultimate measure

of speed; but such an outlay would be beyond all reason. It is

fair, therefore, we think, to rest the burden upon the transportation

shoulders, and predict that with it, and it alone, lies the practical

limit of the speed of railway trains drawn by steam locomotives.

A PRACTICAL EXPERIMENT.

By H. Walter Webb.—3rd Vice-President—New

York Central Railroad

ON September 14, 1891, a train, consisting of a locomotive

and three large private cars, made a run over the New York Central

& Hudson River Railroad, from New York to Buffalo, on a schedule

the most extraordinary on record, and which is destined to exert

an important influence on railroad travel during the next few

years.

The engine was of a new class, especially designed for fast

passenger service by Mr. William Buchanan, the Superintendent

of Motive Power of the road, and built by the Schenectady Locomotive

Works, its total weight in working order being 100 tons. The aggregate

weight of the cars when empty was over 130 tons.

The journey from New York to East Buffalo, a distance of 436-and-32/100

miles, was made in 439-and-45/100 minutes. Allowing for time lost

in changing engines at Albany and Syracuse, and for cooling a

hot journal at Fairport, the run of 436.32 miles was made in 426

minutes, or at the rate of 61.44 miles per hour.

Previous to this run there were scores of records of fast time

made by passenger trains, special and regular, both in this country

and in England. Records of fast runs of 10, 15, or 20 miles were

exceedingly plentiful, but there were few records of long distance

runs that had attracted any special attention. The most remarkable

on record, and the ones that until last September were unequalled

in railroad history, were those made between London and Edinburgh,

in the summer of 1888, when the "race to Edinburgh"

was in progress between the London & Northwestern and the

Great Northern Railways of England. The distance over the former

is 400 miles, and the run was made daily on a schedule calling

for a speed of 53-and-one-third miles per hour. On the Great Northern

the distance is 393 miles, and the schedule in this case called

for a speed of 54 miles per hour.

These trains were run daily for many weeks, and were generally

punctual and within their schedule time. On several occasions,

however, they exceeded the schedule, and made what at that time

were regarded as phenomenal runs.

On August 13, 1888, the Northwestern train covered the distance

of 400 miles in 427 minutes, or at a rate of 56-and-one-fifth

miles per hour, and on August 31st the Great Northern train made

the run of 393 miles in 412 minutes, or at the rate of 57½

miles per hour. These individual runs were both remarkable, but

the daily running of the trains on their published schedules were

regarded by railroad men as still more extraordinary, and at that

time there were no schedule trains in this country that approached

them in point of speed. It must be remembered, however, that these

English roads are possessed of many advantages not enjoyed by

railroads on this side of the water, as, for instance, the long

and numerous tangents, the entire absence of grade crossings,

and, more especially, the light weight of the cars, 80 tons being

the maximum weight of the trains used in the "race to Edinburgh."

With equipment of the character required and used in this country,

provided as it is with all luxuries, conveniences, and comforts,

and a rate of two cents per mile, a train limited to the above

weight could not carry a sufficient number of passengers to enable

it to earn its running expenses.

Three years previous to these English records a special train

weighing 64 tons made a run on the West Shore road from Buffalo

to Weehawken in 9 hours and 23 minutes. In the published accounts

different allowances for stops were made, making the average rate

per mile vary from 51 to 54 miles per hour; either rate, however,

making it the best long-distance run on record in the United States,

until the run from New York to Buffalo, over the New York Central

& Hudson River Railroad, described in the beginning of this

article.

That remarkable run eclipsed and left far behind all records

for long-distance runs formerly made in this country or England.

And to fully appreciate the importance of what was demonstrated

by it, we must remember that within six weeks after it was made

a passenger train was running between those cities on a schedule

two hours shorter than had at any time previously been made by

the fastest limited or mail train, and the air is even now full

of rumors of shorter time to be made on important lines between

great cities during the coming spring and summer, so that it is

not at all improbable, in view of the power now to be obtained

and the public demand for faster service, that in the near future

we shall see trains from New York to Buffalo in 7½ hours,

from New York to Boston in less than 4 hours, and from New York

to Washington in the same time.

But to railroad men and to those familiar with the characteristics

of the New York Central Railroad, between New York and Buffalo,

the record of the trip referred to was far more significant than

was indicated by the mere statement that the run had been at a

speed averaging 61-and-44/100 miles per hour.

They appreciated the fact that the journey out of the Grand

Central Depot, through the Fourth Avenue tunnel, over the Harlem

drawbridge, following the winding curves along the Harlem River

to Spuyten Duyvil, along the banks of the Hudson, through Yonkers,

Peekskill, and Poughkeepsie, rounding the curves of the Highlands,

and taking water twice from tanks between the tracks, meant frequent

reductions of speed in order to make the run in comfort and ease;

and from Albany, west, the long and heavy grade over the hill,

the thriving and prosperous towns of the Mohawk Valley, the slow,

tedious run through the streets of Syracuse, the viaduct at Rochester,

and the 11-mile grade at Batavia, all furnished reminders that

the train must have at times attained a high degree of speed to

have made the average mile at a rate of over 60 miles an hour.

A careful schedule of the running time of each mile was kept,

an analysis of which shows the following:

Four hundred and thirty-six miles were run in 426 minutes.

One hundred and thirty miles were run at a rate of less than

60 miles per hour.

One hundred and eighteen miles were run at a rate varying from

60 to 65 miles per hour.

One hundred and fifty-one miles were run at a rate varying

from sixty-five to seventy miles per hour.

Thirty-seven miles were run at a rate varying from seventy

to seventy-eight miles per hour.

The schedule and analysis certainly indicate a radical change

in the conditions affecting fast passenger train service in this

country. For many years the problem has been to obtain power sufficient

to draw heavy trains long distances at high rates of speed. The

above figures make it evident that steam will without difficulty

furnish power sufficient to take a train heavy enough to be profitable

over a long distance at a rate of speed very much in excess of

an average of 60 miles per hour; and attention is now diverted

from the motive power to other departments of the railroads and

a consideration of whether the roadbed, bridges, tracks, and safety

appliances are such as to permit the use of this power and speed

with entire safety and comfort to passengers.

The question then naturally arises, and is repeatedly asked:

If it is incumbent on most roads to raise their standards of roadways,

tracks, and bridges in order to permit of the use of the best

and most effective power, if the motive-power department is now

in advance of the other departments of railroads, wherein has

there been a change? On what lines and in what particulars has

the locomotive so developed in the past few years as to become

so much superior to what it was before?

The best and most complete answer is a comparison of the distinctive

features of the type of engine now in use on the New York Central

road for fast passenger service with those in use in the same

service two years ago. To fully appreciate the comparison it must

be remembered that the ability of a locomotive to draw a heavy

load a long distance at a high rate of speed is limited.

First, by the capacity of the boiler to furnish steam rapidly

enough and in volume sufficient to supply the demand.

Second, by the adhesion of the engine; that is, the resistance

which prevents or opposes the slipping of the driving wheels on

the rails, and,

Third, by its tractive power; that is, the force by which it

is urged onward by the pressure of steam in the cylinders.

The problem, therefore, presented to Mr. Buchanan in designing

the new type of passenger engine was to obtain greater boiler

capacity, greater adhesion, and greater tractive power. The engine

in use on the New York Central two years ago for the movement

of its fast passenger trains is a fair exponent of the best type

then in use or known. It rendered excellent service and attracted

frequent attention from motive-power men, both here and abroad,

on account of the work it did.

The fire-box of this engine was as large as it was possible

to make it, located where it was between the frames and driving-axles,

its width and length thereby being limited. The problem of increasing

the boiler capacity was for that reason a difficult one, and also

because the weight of the boiler itself in a locomotive and the

space it occupies is necessarily less in proportion to its capacity

than that of any other boiler, and for this reason it must produce

much more steam in a given space of time, in proportion to its

size, than a boiler of any other kind of engine.

To obtain the desired increased boiler capacity and heating

surface, Mr. Buchanan located the fire-box, which formerly was

between the sides or frames of the engine and between the axles

of the driving-wheels, on top of these frames and axles, and by

so doing obtained an increase in the width of the fire-box of

5½ inches and an increase in its length of 25 inches, being

an equivalent of nine and three-quarter square feet of

additional grate area. The boiler flues, which in the former engine

numbered 238, he increased to 268, and by the change in the fire-box

he was enabled to lengthen them 4½ inches, thus obtaining

an increased heating surface of two hundred and twenty-one

and a half square feet, the diameter of the boiler being increased

from 51 to 58 inches. With this increase in the grate area and

heating surface, the desired increase in boiler capacity was obtained.

To secure the adhesion the weight on the four drivers, which

formerly was limited to thirty tons, was increased to over forty,

or, over ten tons' weight on each driving-wheel.

Here, however, came in the question of road-bed, rail, and

bridges, as there are but few roads in the country that would

permit the use of an engine with such weight located on four drivers.

In this case, however, the matter had been fully provided for

and extensive alterations had been made to many bridges, a large

amount of work done on the road-bed, and the old and lighter form

of rail removed and replaced with the standard 80-pound section.

To increase the tractive power of the engine the cylinders were

enlarged 1 inch in diameter; being formerly 18 x 24, they were

now made 19 x 24.

All these changes had vastly increased the height and weight

of the engine, and by some faint-hearted friends the criticism

was freely made that its use would be destructive of roadway,

tracks, and bridges. These objections, however, were more than

met by a departure from the usual and by original methods of suspending

the engine on its springs. Formerly the springs were placed on

top of the driving-boxes; in this case they were located beneath

them and connected with equalizing bars, thus allowing the use

of a longer and more elastic spring than was formerly used, and

it has been demonstrated that these engines are less destructive

to road-bed and rail, are freer from the swaying motion usually

found in engines hung from above the driving-boxes, and ride smoother

and more comfortably than any in the service.

Of course, to obtain the speed that was sought, it was desirable

to increase the diameter of the driving-wheels; but this was not

done at first, nor until it was ascertained how successful had

been the efforts to increase the boiler capacity of the engine.

When it was found that this increase was ample, and even more

successful than had been hoped for, the driving-wheels were changed

and the new ones of 6 feet 6 inches in diameter, or 8 inches larger

than the old ones, were attached. The gain in speed is most apparent

and can well be appreciated when it is remembered that the large

driver makes 29.51 less revolutions in a mile than the small ones.

On a trip from New York to Albany the decrease in the number of

revolutions by the large 6 foot 6 inch wheel would be 4,219.93,

an equivalent of 86,154.09 feet, or a saving of nearly 16-and-one-third

miles. From New York to Buffalo the saving would be nearly 50-and-1/100

miles.

With a locomotive such as this for motive power it is not a

difficult matter to run profit-paying passenger trains over long

distances at a running rate of over a mile a minute; this, of

course, assuming we have proper character of roadbed and rails

and approved appliances to insure safety and rapid speed.

That the speed of passenger trains in this country is destined

to rapidly increase in the near future seems certain. There is

nothing in railroading that renders such large and quick returns

to the management as catering to the wants and desires of the

travelling public. Nothing so fully exemplifies this as the immense

change that has taken place in the past five years in the equipment

of through express trains from the seaboard to the West and Southwest.

The luxury and comfort that can today be obtained on one of

the many limited trains passing over any of the great trunk lines,

is in strong contrast to what was furnished five or six years

ago, and it would seem that there was not much room for further

improvement in that direction. What the public are now seeking,

and what will certainly be furnished, is fast time; and that this

is appreciated by railroad managers is well evidenced by the large

sums that are now being spent to perfect the roadways of the more

important lines.

One word, in closing, in regard to the alleged danger of the

fast train. It is most emphatically untrue that it is more dangerous

than other trains. Those familiar with the subject will agree

that the very reverse is the case. As an eminent English authority

writes, "With picked engineers, trainmen, and firemen, with

the best and newest rolling-stock and the most perfect engines

the company possesses, with every signalman and flagman all down

the line on the qui vive, it is difficult to see where

there comes in any special source of danger." And in addition

to this, it must be remembered that fast trains such as are now

being run on many roads in this country would be simply impossible

without the vigorous discipline, the constant energy, the keenest

exactitude, and the care and attention to the details of the service

that is the surest and most effective guard against accidents.

Stories Page | Contents Page

|