|

Scientific American—April 4, 1903

ELECTRIC TRACK WELDING.

BY WALDON FAWCETT.

Marked improvements have been made during the past two years

in the process of electrically welding rail joints. Although by

the process which has been used since 1897 the breakage on all

welding did not exceed one per cent, the new system has reduced

the percentage of breakage to less than one-tenth of one per cent.

In the city of Rochester, N.Y., where the new process was rarely

employed, more than 5,300 joints were welded during the latter

part of 1901. An examination in the spring of 1902 disclosed only

six broken rails. None of the damaged rails had a joint broken

through the bars or a weld pulled off; practically all of the

breaks occurred through the existence of old bolt or bond holes

beyond the bars.

The

new plan of welding has been still further improved to meet such

exigencies, and now all welding bars are made long enough to reach

over bolt and bond holes, so that in the future even this source

of breakage will be practically eliminated. The remarkable state

of perfection to which electric track welding has lately been

brought appears all the more marvelous in view of the fact that

in the latest approved method employed, each weld depends on the

judgment of the man making it, and must necessarily remain in

the track and await the strain of winter to disclose defects,

if any exist. Even under these circumstances, however, not one

weld in a thousand fails to successfully stand the actual test. The

new plan of welding has been still further improved to meet such

exigencies, and now all welding bars are made long enough to reach

over bolt and bond holes, so that in the future even this source

of breakage will be practically eliminated. The remarkable state

of perfection to which electric track welding has lately been

brought appears all the more marvelous in view of the fact that

in the latest approved method employed, each weld depends on the

judgment of the man making it, and must necessarily remain in

the track and await the strain of winter to disclose defects,

if any exist. Even under these circumstances, however, not one

weld in a thousand fails to successfully stand the actual test.

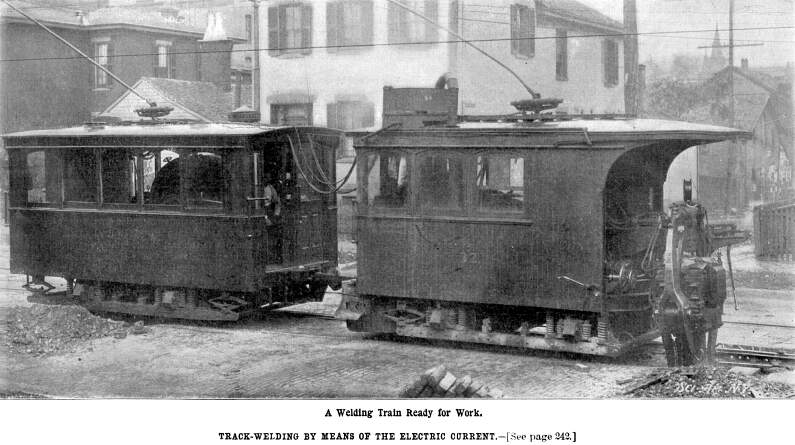

The machinery employed in electric track welding and it is

of a very ingenious character—is mounted on trolley cars

of special design, the running gear of which is provided with

threaded axles, so that the machines can be used to weld track

of almost any gage. The welding of newly-laid rails is done either

before or after the paving is in place, space being left at the

joints to permit the entrance of the welder. When welding is to

be done on rails which have been in place for some time, the paving

is torn up around each joint, and the old plates and bond wires

removed. It is necessary, of course, in such instances, to bring

the rail ends up to the proper grade.

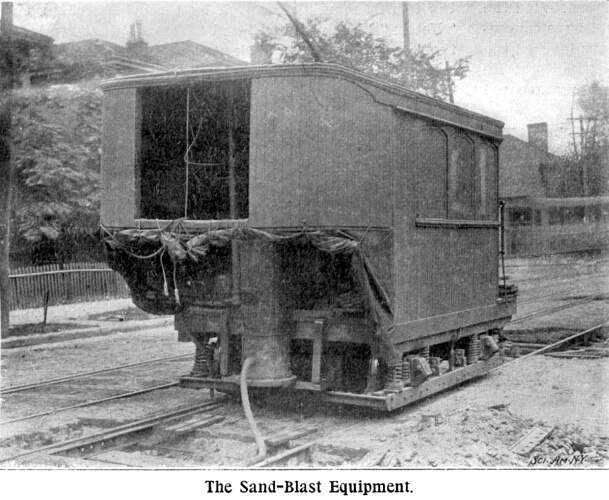

The new method of electrical welding comprises three distinct

operations. The first step is that of sand-blasting, whereby all

the dirt, rust, and foreign matter is removed from the rails,

at points where welds are to be made, and also from the bars used

in making the joint. Sand-blasting necessitates the employment

of apparatus, including a ten horse power motor driving an air

compressor, an air storage tank, a sand bin and sand mixer. A

hose and nozzle enables the operator to direct the blast of air,

carrying the sand against the rails, so that all foreign matter

is quickly removed.

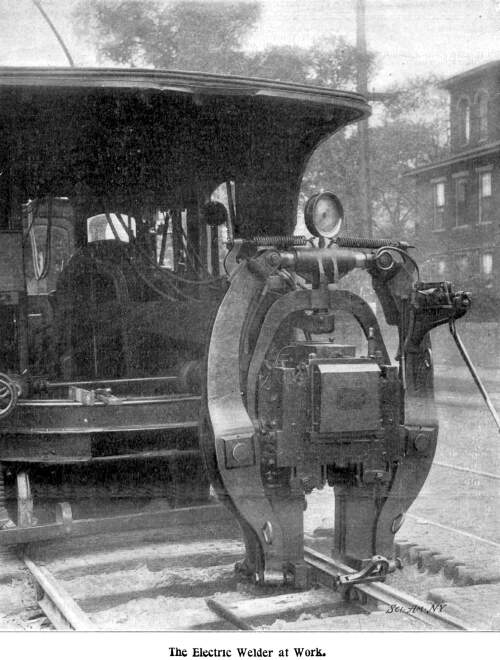

Two cars are required to carry the apparatus for welding, which

constitutes the second step in the work. The welder itself is

hung from a bail on a, crane, extending out beyond the end of

one car. This crane is so arranged that the jaws of the welder

can engage the sides of the rail, and also shift from one side

to the other, thus enabling work to be carried out on both rails

of the track. The operation of this crane is accomplished by means

of friction clutches, from a shaft in the car, which shaft is

kept running continuously by a five horse power motor.

The motor also drives a small rotary pump, which circulates

water through the welding transformer and the faces of the contacts,

thereby keeping them cool. The water, after it has passed through

the welder, is elevated to a cooling tank on top of the car. It

is of course desirable that this water shall be cooled just as

rapidly as possible, for which purpose a novel plan is employed.

Starting from the middle of the tank, and passing around and around

until the outer circumference of the tank is reached, is a serpentine

partition. A perforated false bottom is provided, through which

air is forced from a powerful blower. The hot water from the welder

passes into the outer portion of the serpentine partition, and

is subjected constantly to the modifying influences of the forced

air. After reaching the center of the serpentine partition, the

cooled water is conducted to one of the tanks in the car.

The welding apparatus proper consists of an alternating current

transformer, the primary winding of which is made up of two coils

in parallel, each of forty-four turns. A single loop of copper

of large cross section forms the secondary coil; and the terminals

constitute the contacts or jaws, which engage each side of the

rail, and between which the weld is made. Supporting the transformer

on either side, although insulated from it, are large levers hinged

together at about two-thirds of the distance from the top, which

levers are used to transmit the necessary pressure to the weld.

A hydraulic jack connects these levers at the top. A pressure

of over two tons per square inch is obtained on the rams of the

jack, which are less than four-inch diameter; and inasmuch as

this is increased by the leverage of the arms, the pressure developed

at the weld is in excess of thirty-seven tons.

For making a joint there are employed flat-rolled steel bars

which have on one side, at either end, bosses or projections,

serving as contact points between the bars and the web of the

rail, and confining the welded area of these sections. About the

middle of the bars on the same side with the projections is placed

a flat strip of steel, perhaps one-eighth of an inch in thickness

and one inch wide. The bars are supported on small blocks, and

so placed across the joint that the middle strip engages the web

of both rails. The end welds are horizontal, while the middle

weld is vertical and the full width of the bar.

The whole operation

of welding is conducted very expeditiously. When the welding train

of two cars is moved up to a joint, the welder is swung into place

and the jaws made to press against the bars on each side of the

rail. The current is then turned on and flows from contact to

contact through the bars and the rail web. By altering the pressure

on the jaws, the resistance of the several junctures is increased,

and the whole is soon brought up to a welding heat. When this

point is reached the current is cut off, and simultaneously the

pressure is brought up to the full amount. Affix the pressure

is loosened, the welder car is moved back, in order to bring the

jaws opposite the extremity of the bars, and here the same process

is repeated, with the addition that when the final pressure is

applied, it is held there and the weld permitted to cool under

pressure, until no glow is apparent. Then the welder is moved

forward to the other end of the bar, and the process is repeated,

after which the welder is swung to the opposite side of the car

and the joint on the other side is welded. The whole operation

of welding is conducted very expeditiously. When the welding train

of two cars is moved up to a joint, the welder is swung into place

and the jaws made to press against the bars on each side of the

rail. The current is then turned on and flows from contact to

contact through the bars and the rail web. By altering the pressure

on the jaws, the resistance of the several junctures is increased,

and the whole is soon brought up to a welding heat. When this

point is reached the current is cut off, and simultaneously the

pressure is brought up to the full amount. Affix the pressure

is loosened, the welder car is moved back, in order to bring the

jaws opposite the extremity of the bars, and here the same process

is repeated, with the addition that when the final pressure is

applied, it is held there and the weld permitted to cool under

pressure, until no glow is apparent. Then the welder is moved

forward to the other end of the bar, and the process is repeated,

after which the welder is swung to the opposite side of the car

and the joint on the other side is welded.

The present plan of holding the pressure after the completion

of the weld increases the strength of the weld very materially.

Only the ends are so treated, the center weld being subjected

to so slight a strain that such a precaution is unnecessary. One

of the improved processes of the new plan of welding grows out

of the discovery that it is advantageous to weld the ends of the

bars while the bars are in an expanded state. By making the center

weld first, and not stopping to cool it under pressure, the greatest

elongation of the bars is, of course, secured. As the bars cool

off, after the ends are welded, they shrink and exert a powerful

pull to bring together the abutting rail ends, thus closing the

slightest opening and leaving practically no joint whatever.

The advance in this direction is of greater significance than

might at first be imagined, for in the manufacture of a continuous

rail, the abutting rail ends, if not brought firmly together,

give the metal in the head of the rail an opportunity to flow

into the opening between the rails. This will in. time cause a

low spot in the head of the rail. The bars being always in a state

of tension, the rail inclosed between the bars is necessarily

in a state of compression; and inasmuch as any contraction of

the rail between the joints will be transmitted to. the end welds,

it is obviously necessary that these latter be as tough as possible,

that they may withstand the strain. The center weld merely contributes

to vertical stiffness, and tends to prevent any movement of the

rail ends.

The current actually used in welding operations by this new

plan approximates from 25,000 to 30,000 amperes at 7 volts. The

car accompanying the welder carries a rotary converter for changing

the direct current from the trolley to an alternating current.

The current in the primary coils of the welder is a 40-cycle alternating,

at 300 volts; and the direct-current side of the rotary converter

is capable of taking from the trolley, current at from 325 to

600 volts. By means of the regulating apparatus, a constant supply

to the welder of 300 volts is maintained, regardless of fluctuations

on the line. At a voltage of 500, about 225 amperes is required

on a line, or, in other words, about 125 kilowatts is required

to make a weld, the time consumed, or rather the interval during

which the current is on, being two and a half minutes.

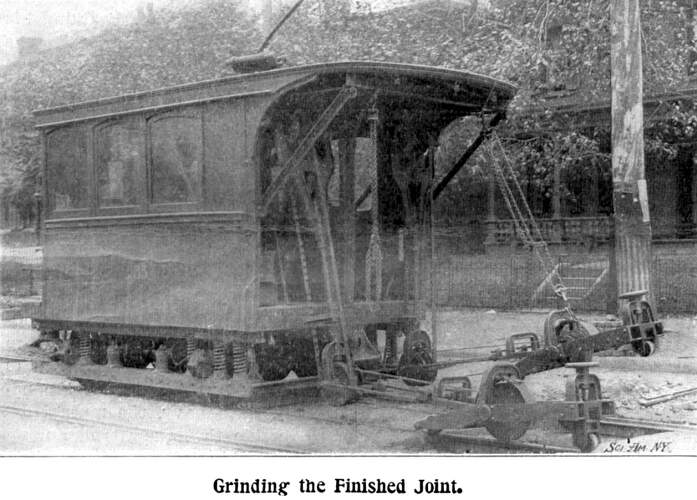

The final operation of welding consists in grinding the head

of the rail to a true surface. There is comparatively little need

for this finishing process where new rails are being welded, but

in old track it is very essential, inasmuch as the receiving rail

is purposely welded higher than the other. The grinder, which

is used to grind out the inequalities in the rail head and bring

it back to a true surface, consists of an emery wheel mounted

on a carriage having two rollers which are about four feet apart.

The carriage is let down on the rail, so that the rollers roll

along the head of the rail, and the emery wheel is thus over the

uneven portion at the joint. A swing frame connects this carriage

with a motor on the car, and the operator is thus enabled to move

the emery wheel back and forth over the joint while the car remains

stationary. A hand wheel enables the emery wheel to be gradually

fed down, and as it is moved forward and back the high places

are ground off until the whole joint is brought to a true surface.

In many respects the operation corresponds to the manipulation

of the ordinary carpenter's plane. When carried on as a continuous

process, only about fifteen minutes are required to complete a

joint; and when operations are conducted day and night, at least

eighty joints are completed in 24 hours.

Track Page

| Contents Page

|