|

1038

RAILS.

1607. Care in Unloading Steel.—Rails are

often bent in consequence of careless handling. There is no excuse

for either foremen or workmen for this. The rails are unfit for

laying until straightened, but they are often laid in a bent state,

giving a bad surface and line. The surest remedy is proper handling.

The rails are always loaded properly at the rolling mill,

and the kinks are put in them either in transfer or in delivering

on the grade. When rails are to be transferred from one car to

another, rails of suitable length should be used as skids upon

which the rails to be transferred are pushed from one car to another.

When from scarcity of flat cars, rails are shipped in box cars,

rollers are placed in the end doors of the box car, and the rails

are rolled as they are transferred. The rails should always be

placed in regular order, as shown in Fig. 492.

In unloading, there should be enough men to handle the rails

with ease and dispatch. The rail should be lifted clear

1039

of the car floor and carried to the edge of the car. All should

be ready, and at the word, the rail dropped clear of the car so

that it will fall in the position shown in Fig.

493, in which position the danger of kinking is entirely avoided.

Other men should stand on the ground removing each rail as soon

as it drops, so that one rail shall not fall on top of another.

Rails must not be dropped from the cars on rock or loose stones,

but on dirt, which will insure their safety.

None but the best men should be employed on the steel car.

They should be strong physically, understand plain English thoroughly,

and be prompt and active. When men, because of difference of nationality,

fail to readily understand each other, confusion is sure and accident

almost certain to follow. The same gang of men should handle all

the steel. If the track laying is to be rushed, at least two,

and better three, steel cars should be provided, which permits

of one being constantly at the front. As soon as a load of steel

is transferred from the flat car to the steel car, a team of horses

should be hitched to it and the car hauled to the front. The steel

men at the front, having unloaded their car, return with it until

they meet the loaded car. They then lift their empty car from

the rails to the side of the track, allowing the loaded car to

pass. The steel men push the loaded car the balance of the way

unless the grade is heavy enough to require a team.

Steel cars should be light and strong, and capable of carrying

a heavy load. The car should be of such weight as to be readily

handled by the steel crew. The wheel base should be 8 inches in

width, so that the car may pass safely over rough and poorly gauged

track.

1608. Straightening Rails.—If from any cause, rails

should be bent, they should be carefully straightened before being

placed in the track. If kinked, i.e., bent laterally as shown

in Fig. 494,

they may be straightened by

1040

nicking the flange of the rail with a cold chisel on the convex

side of the rail at the point A where the bend is the sharpest.

Then, laying the rail on its base, a few sharp blows with a sledge

on the side of the head of the rail at the point A will remove

the kink. Kinks may also be removed by means of a rail bender

or jim crow, shown in Fig.

495. The jim crow consists of two heavy hooks a and

b, which fit over the head of the rail. The curved bar

c, which unites these hooks, is drilled at its crown, and

threaded to receive the screw d. The cross-bar e unites

with the two hooks a and b, and serves as a guide to the

screw d. Force is applied to the screw by means of the

wrench f, having a long handle.

If surface-bent, as shown at A in Fig. 496, they are easiest straightened

with the jim crow. The straightening of the rails before laying

will avail but little unless the ties are

1041

well bedded, and all of the rails given a good bearing when

the track is laid.

1609. Curved Rails.—Rails laid on curves should

always be curved before being placed in the track. When laying

track on new road, it is a much better policy to curve the rails

in the material yard before forwarding to the track-layers. The

material foreman should have a list of the curves in the same

order in which they occur in the track. He should be able to determine

the middle and quarter ordinates of a 30-ft. rail for any degree

of curve, and should curve each rail accordingly. His list of

curves will give the station of the P. C. and P. T. of each, from

which he will determine the length of each curve and the number

and length of rails required for each. These rails should be marked

with the number of the degree of the curve for which they are

intended, and the rails for each curve should be kept separate

from the other rails by pieces of board, so as to prevent any

confusion when they arrive at the front. One 29½-foot rail

is laid for each 6 degrees of angle in the curve; hence, for a

curve with a central angle of 30 degrees, the number of 29½-ft.

rails required is 30/6 = 5. In laying the track, the short rails

should be equally distributed throughout the curve. The rails

are curved either with a rail bender, shown in Fig.

495, or by the aid of a track lever and curving hook, shown

in Fig. 497.

The latter process is as follows: A tie A is placed

under each end of the rail B which is to be curved. A hook

C is placed under the main track rail

1042

between two ties, at about 6 feet from the end of the rail

to be curved. The track lever D is then let into the hook

C, and the men pry down upon the rail B, giving

it the required curve. The quarter points should always be curved

before the center, as it often happens that the center curves

with the quarter points, thus saving time.

The practice of curving rails by dropping them across two ties,

or pounding them with a sledge hammer, can not be too severely

condemned. By the former method, an angle instead of a curve is

often put in the rail, and sledging is liable to break a rail

outright, or, at least, put a flaw in it which may result in actual

fracture when laid in the track. Some of the worst accidents on

record have been caused by broken rails, weakened by hard usage

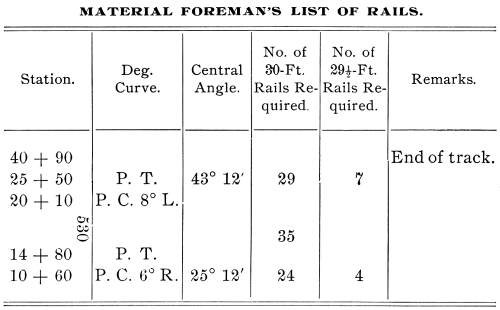

while being curved. The following table contains a list of curves

and tangents and the number and lengths of rails required for

each. With such a list, the material foreman can forward the rails

curved and assorted. His facilities for curving rails should be

of the best, and with a skilled gang of men he can turn off much

more and better work than would be possible at the front:

1610. Assorting Rail Lengths.—Rails of different

lengths should never be laid promiscuously. The short

1043

rails should be piled by themselves in the supply yard and

forwarded to the track-layers in such order and numbers as they

may require. On curves, as the inner rail forms a smaller circle

than the outer rail, it is sure to gain, and to maintain the joints

in the same relative position, this gain must be compensated by

the use of short rails. A list of the curves and the number of

short rails required for each should be given to the supply foreman,

whose business it is to forward the track material in the order

named on the list. This table shows how the material foreman makes

out his list.

Track Page

| Contents Page

|