|

1043

EXPANSION AND CONTRACTION.

1611. In laying track, provision must be made for expansion

and contraction of the rails, due to changes of temperature. As

the temperature rises the rail lengthens, and unless sufficient

space is left between the ends of the rails to allow for the expansion,

the ends of the rails abut one against another with such force

as to cause the rails to kink or buckle, marring the appearance

of the track and rendering it unsafe for trains, especially those

running at high speeds. If, on the other hand, too much space

is left between the rails, the contraction or shortening of the

rails due to severe cold may do equally great harm by shearing

off the bolts from the splice bars, leaving the joints loose and

unprotected. The coefficient of expansion, i.e., the amount of

the change in the length of an iron bar due to an increase or

decrease of 1 degree F. is taken at .00000686 per degree per unit

of length.

EXAMPLE.—If an iron rod measures 30.015 ft. at a temperature

of 90 degrees, what is its normal length, assuming 60 degrees

as the normal temperature? The temperature of the bar must be

90 degrees - 60 degrees = 30 degrees above the normal temperature.

SOLUTION.—As the increase in length is .00000686 ft. per

degree for each foot in length of the bar, the total increase

for 1 foot of the bar due to a rise of 30' in temperature is .00000686

x 30 = .0002058 ft., and for 30 ft. the increase in length above

the normal is .0002058 x 30 = .006174 ft , or about one-sixteenth

of an inch. As the rail at a temperature of 90 degrees measures

30.015 ft., of which length .00617 ft., say, .006 ft., is due

to expansion, the normal length of the rail is 30.015 - .006 =

30.009 ft.

1044

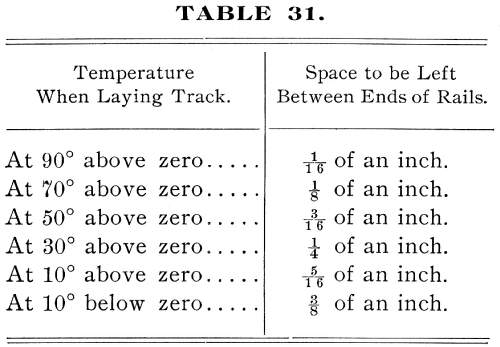

To provide against the effect, of expansion, an opening is

left between the ends of the rails, and to provide against contraction,

the holes in both rail and splice bar are made oblong, allowing

about ¼-inch for extreme movement. The following table

of expansion is a safe guide to track-layers for most latitudes

in the temperate zones:

To give to the track the proper opening at the joints, expansion

shims are used. They are made of iron, and are of various

forms. A simple and effective shim is made by bending a piece

of one-eighth inch iron into the form of a right angle, as shown

in Fig. 498.

This gives a combination shim of two thicknesses, viz., one-sixteenth

and one-eighth inches. After the angle is formed, the one-sixteenth-inch

shim is obtained by hammering the one-eighth-inch bar to the required

thickness. The thickness of each shim should be clearly stamped

upon it. When put in place, the shim reaches the full depth of

the head of the rail, and the bent portion lies flat on the top

of the rail. The shims should not be removed until the joint is

1045

full bolted, and there should be a sufficient number of them

on hand to keep the track-layers constantly employed, and not

require them to wait until shims can be removed from bolted joints.

Track Page

| Contents Page

|