|

CHAPTER XVII.

THE VALVE-MOTION.

THE LOCOMOTIVE SLIDE-VALVE.

THE nature of the service required of locomotive engines,

especially those employed on fast-train service, makes it necessary

that the steam-distribution gear shall be free from complication;

and, for convenience in working the engine, it is essential that

means should be provided for reversing the motion promptly, without

endangering the working-parts. The valve-gear should also be capable

of regulating the admission and exhaust of steam, so that the

engine shall be able to maintain a high rate of speed, or to exert

a great tractive force. These features are admirably combined

in the valve-gear of the ordinary locomotive. Designers of this

form of engine have given great consideration to the merit of

simplicity. Numerous attempts have been made to displace the common

D slide-valve, but every move in that direction has ended in failure.

INVENTION AND APPLICATION OF THE SLIDE-VALVE.

The slide-valve, in a crude form, was invented by Matthew

Murray of Leeds, England, towards the end of last century; and

it was subsequently improved by Watt to the D form. It received

but little application in England till the locomotive era. Oliver

Evans of Philadelphia appears to have perceived the advantages

possessed by the slide-valve, for he used it on engines he designed

years before locomotives came into service. The D slide-valve

was better adapted for high-speed engines than any thing tried

during our early engineering days, but it was on locomotives where

it first properly demonstrated its real value. The period of necessity

brought the slide-valve into prominence; and the galaxy of mechanical

genius that heralded the locomotive into successful operation

recognized its most valuable features, and it soon obtained exclusive

possession of that form of engine. Through good and evil report,

and against many attempts to displace it, the slide-valve has

retained a monopoly of high-speed reversible engines.

DESCRIPTION OF THE SLIDE-VALVE.

The slide-valve in common use is practically an oblong

cast-iron box, which rests and moves on the valve-seat. In the

valve-seat, separated by partitions called bridges, are three

ports, those at the ends being the openings of the passages for

conveying steam to and from the cylinders, while the middle port

is in communication with the blast-pipe, which conveys the exhausted

steam to the atmosphere. On the under side of the valve is a semicircular

cavity, which spans the exhaust-port and the bridges when the

valve stands in its central position. When the steam within the

cylinder has performed its duty of pushing the piston towards

the end of the stroke, the valve cavity moves over the steam-port,

and allows the steam to pass into the exhaust-port, thence into

the exhaust-pipe. The cavity under the valve thus acts as a door

for the escape of the exhaust steam. This is a very convenient

and simple method of educting the steam; and the process helps

to balance the valve, since the rush of escaping steam striking

the under part of the valve tends to counteract the pressure that

the steam in the steam-chest continually exerts on the top of

the valve.

PRIMITIVE SLIDE-VALVE.

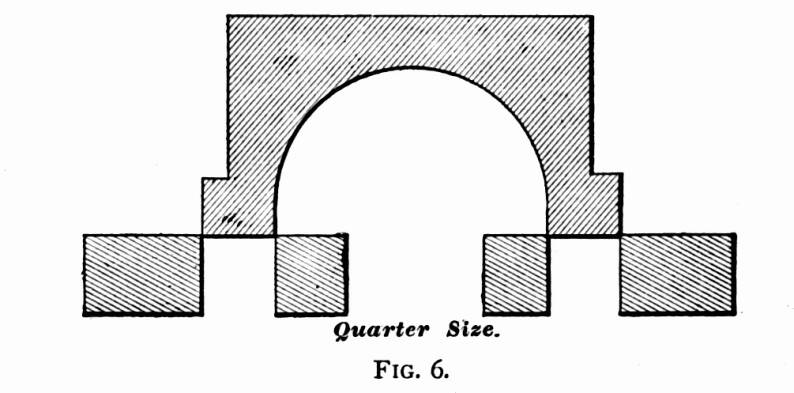

In its primitive form, the slide-valve was made merely

long enough to cover the steam-ports when placed in the central

position, as shown in Fig. 6. With a valve of this form, the slightest

movement had the effect of opening one end so that steam would

be  admitted to

the cylinder, while the other end opened the exhaust. By such

an arrangement, steam was necessarily admitted to the cylinder

during the whole length of the stroke; since closing at one end

meant opening at the other. There were several serious objections

to this system. It was very difficult to give the engine cushion

enough to help the cranks over the centers without pounding, and

a small degree of lost motion was sufficient to make the steam

obstruct the piston during a portion of the stroke. But the most

serious drawback to the short valve was, that it permitted no

advantage to be taken of the expansive power of steam. For several

years after the advent of the locomotive, the boiler pressure

used seldom exceeded fifty pounds to the square inch. With this

tension of steam, there was little work to be got from expansion

with the conditions under which locomotives were worked; but,

so soon as higher pressures began to be introduced, the loss of

heat entailed by permitting the full-pressure steam to follow

the piston to the end of the stroke became too great to continue

without an attempted remedy. A very simple change served to remedy

this defect, and to render the slide-valve worthy of a prominent

place among mechanical appliances for saving power. admitted to

the cylinder, while the other end opened the exhaust. By such

an arrangement, steam was necessarily admitted to the cylinder

during the whole length of the stroke; since closing at one end

meant opening at the other. There were several serious objections

to this system. It was very difficult to give the engine cushion

enough to help the cranks over the centers without pounding, and

a small degree of lost motion was sufficient to make the steam

obstruct the piston during a portion of the stroke. But the most

serious drawback to the short valve was, that it permitted no

advantage to be taken of the expansive power of steam. For several

years after the advent of the locomotive, the boiler pressure

used seldom exceeded fifty pounds to the square inch. With this

tension of steam, there was little work to be got from expansion

with the conditions under which locomotives were worked; but,

so soon as higher pressures began to be introduced, the loss of

heat entailed by permitting the full-pressure steam to follow

the piston to the end of the stroke became too great to continue

without an attempted remedy. A very simple change served to remedy

this defect, and to render the slide-valve worthy of a prominent

place among mechanical appliances for saving power.

OUTSIDE LAP.

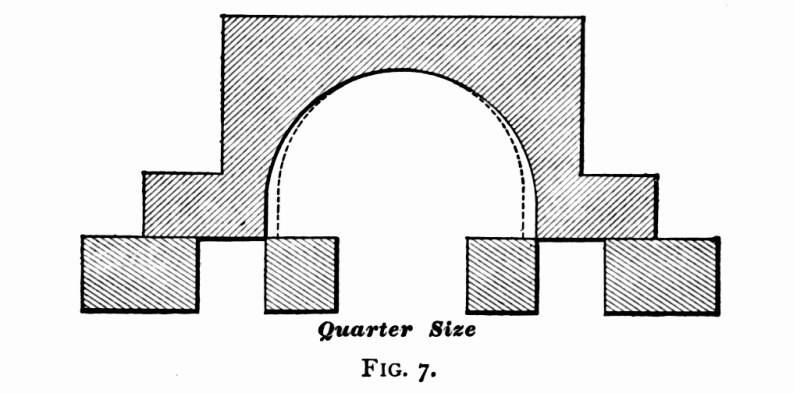

The change referred to, which so greatly enhanced the

efficiency of the slide-valve, consisted in lengthening the valve-face,

so that, when the valve stood in the center of the seat, the edges

of the valve extended a certain distance over the induction ports,

as in Fig. 7. This extension of the valve is called outside lap,

or simply lap. The effect of lap is to close the steam-port before

the piston reaches the end of the stroke, and the point at which

the steam-port is closed is known as the point of cut-off. When

the steam is cut off, and confined within the cylinder, it pushes

the piston along by its expansive energy, doing work with heat

that would be lost were the cylinder left in communication with

the steam-chest till the end of the stroke.

When a slide-valve

is actuated by an eccentric connected directly with the rocker-arm

or valve-stem, the point of cut-off caused by the extent of lap,

remains the same till a change is made on the valve, or on the

throw of the eccentric, unless an independent cut-off valve be

employed. Locomotives having the old hook motion worked under

this disadvantage; because the hook could not vary the travel

of the valve, which is the method usually resorted to for producing

a variable cut-off. The link and other simple expansion gears

perform their office of varying the cut-off in this way. When a slide-valve

is actuated by an eccentric connected directly with the rocker-arm

or valve-stem, the point of cut-off caused by the extent of lap,

remains the same till a change is made on the valve, or on the

throw of the eccentric, unless an independent cut-off valve be

employed. Locomotives having the old hook motion worked under

this disadvantage; because the hook could not vary the travel

of the valve, which is the method usually resorted to for producing

a variable cut-off. The link and other simple expansion gears

perform their office of varying the cut-off in this way.

SOME EFFECTS OF LAP.

In addition to cutting off admission of steam before

the end of the stroke, lap requires the valve to be set in such

a way that it has also the effect of leading to the exhaust-port

being opened before the end of the stroke. The point where the

exhaust is opened is usually known as the point of release. The

change which causes release to happen before the piston completes

its stroke, leads to the closure of the exhaust-port before the

end of the return stroke is reached, which imprisons the steam

remaining in the cylinder, causing compression. Where a valve

has no inside lap, release and compression happen simultaneously;

that is, the port at one end of the cylinder is opened to release

the steam, and that at the other end is closed, letting the piston

compress any steam remaining in the cylinder into the space left

as piston clearance.

INSIDE LAP.

In some cases the inside edges of the valve cavity

do not reach the edges of the steam-ports when the valve is on

the middle of the seat, but lap over on the bridge a certain distance,

as shown by the dotted lines in Fig. 7. This is called inside

lap, and its effect upon the distribution of steam is to delay

the release. By this means it prolongs the period of expansion,

and hastens compression on the return stroke. Inside lap is an

advantage only with slow-working engines. When high speed is attempted

with engines having much inside lap, the steam does not have enough

time to escape from the cylinders, and the back pressure and compression

become so great as to be very detrimental to the working of the

engine. As locomotive engineers have it, the engine is "logy."

THE EXTENT OF LAP USUALLY ADOPTED.

In locomotive practice, the extent of lap varies according

to the character of service the engine is intended to perform.

With American standard gauge engines, the lap varies from 2 inch to 14

inch. For high-speed engines, the extent of lap ranges

from d to 14.

Freight engines commonly get s

to w outside lap, and from

z to 4

inside lap. With a given travel, the greater the lap the

longer will the period for expansion be.

FIRST APPLICATION OF LAP.

Lap was applied to the slide-valve in this country

before its advantage as an element of economy was understood in

Europe. As early as 1829, James of New York used lap on the valves

of an engine used to run a steam-carriage; and in 1832 Mr. Charles

W. Copeland put a lap-valve on a steamboat engine, and his father

understood that its advantage was in providing for expansion of

the steam. Within a decade after our first steam-operated railroad

was opened, the lap-valve became a recognized feature of the American

locomotive; but the cause of the saving of fuel, effected by its

use, was not well comprehended. Many enlightened engineers attributed

the saving to the early opening of the exhaust, brought about

where outside lap was used, which they theorized reduced back

pressure on the piston; and in that way they accounted for the

enhanced economy resulting from the application of lap. It was

not till Colburn applied the indicator to the locomotive, that

the true cause of economy was demonstrated to be in the additional

work taken from the steam by using it expansively.

THE ALLEN VALVE.

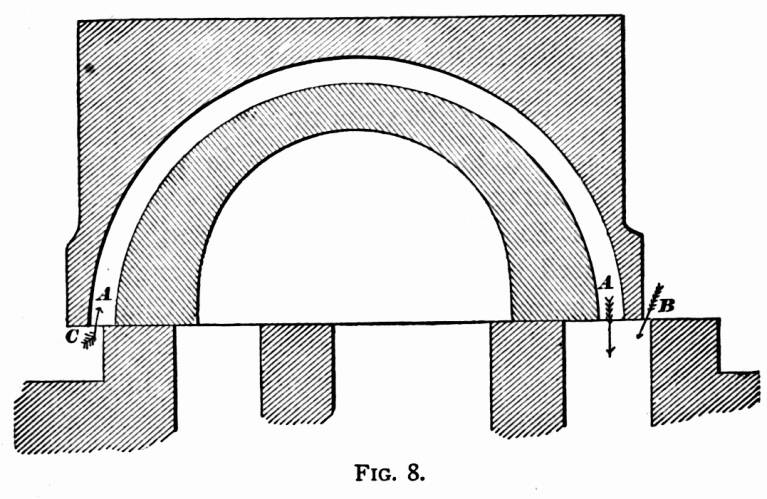

An improvement on the plain D slide-valve has

been effected in a simple and ingenious manner in the Allen valve,

which is receiving considerable favor for high-speed locomotives.

This valve is shown in Fig. 8. The valve has a supplementary  steam-passage, A,

A, cast above the exhaust cavity. The valve and seat are

so arranged, that, so soon as the outside edge of the valve begins

to uncover the steam-port at B, the supplementary passage

begins receiving steam at C; and this gives a double opening

for the admission of steam to the port when the travel is short.

As the travel of the valve is always short when an engine is running

at high speed, the advantage of this double opening is very great;

for it has the effect of admitting the steam promptly at the beginning

of the stroke, and maintaining a full pressure on the piston till

the point of cut-off. steam-passage, A,

A, cast above the exhaust cavity. The valve and seat are

so arranged, that, so soon as the outside edge of the valve begins

to uncover the steam-port at B, the supplementary passage

begins receiving steam at C; and this gives a double opening

for the admission of steam to the port when the travel is short.

As the travel of the valve is always short when an engine is running

at high speed, the advantage of this double opening is very great;

for it has the effect of admitting the steam promptly at the beginning

of the stroke, and maintaining a full pressure on the piston till

the point of cut-off.

ADVANTAGES OF THE ALLEN VALVE.

With an ordinary valve cutting off at six inches, and

having five inches eccentric throw, the port opening seldom exceeds

a inch. It is a hard matter

getting the full pressure of steam through such a small opening

in the instant given for admission. If an Allen valve is used

with that motion, the opening will be double, making w

inch, which makes an important difference. The practical

effect of a change of this kind is that an engine will take a

train along, cutting off at six inches with the Allen valve, when,

with the ordinary valve, the links would have to be dropped to

eight or nine inches. The valve can be designed to work on any

valve-seat, but the dimensions given in Fig. 8 are those that

have been found most satisfactory with our large passenger engines.

In designing an Allen valve for an old seat, it is sometimes advisable

to widen the steam-ports a quarter of an inch or more, by chamfering

off the outside edges that amount. Care must be taken to prevent

the valve from traveling so far as to put the supplementary port

over the exhaust-port, for that would allow live steam to pass

through. The proper dimensions can best be schemed out on paper

before making the required change on the seat.

In very carefully conducted experiments made on the Boston

and Albany Railroad, to compare the performance of the Allen valve

with an engine equipped with a common valve, it was found that

the Allen valve effected a fuel saving of seven per cent.

CASE WHERE THE ALLEN VALVE PROVED ITS

VALUE.

On one of the leading railroads in this country, an

engineer was running a locomotive on a fast train where it was

a hard matter making the card-time. A few minutes could be saved

by passing a water-station; but this was done at serious risk,

for the tender would nearly always be empty by the time the next

water station was reached. The master mechanic of the road determined

to equip this engine with the Allen valve: and, after the change

was made, there was no risk in passing the water-station; for

there always was a good margin of water in the tank when the next

watering-place was reached. The engine seemed to steam better,

because the work was done with less steam; and there was a decided

saving of fuel. The change made the engine smarter, and there

seems to be no limit to the speed it can make. This valve can

be applied to any locomotive with trifling expense. When an engine

is designed specially for the Allen valve, the steam ports and

bridges are usually made a little wider than for the ordinary

valve. The only real difficulty in adopting the valve is getting

the casting properly made, so that the supplementary port will

not be too rough for the passage of steam, and the thin shell

will be strong enough to stand the pressure.

INSIDE CLEARANCE.

For high-speed locomotives, where there is great necessity

for getting rid of the exhaust steam quickly, the valves are sometimes

cut away at the edges of the cavity, so that, when the valve is

placed in the middle of the seat, it does not entirely cover the

inside of either of the steam-ports. This is called inside clearance.

In many instances inside clearance has been adopted in an effort

to rectify mistakes made in designing the valve-motion, principally

to overcome defects caused by deficiency of valve-travel. The

fastest locomotives throughout the country do not require inside

clearance, because their valve-motion is so designed that it is

not necessary. Inside clearance induces premature release, and

diminishes the period of expansion. Consequently inside clearance

wastes steam, and ought to be avoided.

LEAD.

There are certain advantages gained in the working

of a locomotive, by having the valves set so that the steam-port

will be open a small distance for admission of steam, when the

piston is at the beginning of the stroke. This opening is called

lead. On the steam side of the valve the opening is called steam-lead:

on the exhaust side it is called exhaust-lead. Lead is generally

produced by advancing the eccentric on the shaft, its effect being

to accelerate every event of the valve's movement; viz., admission,

cut-off, release, and compression. In the most perfectly constructed

engines, there soon comes to be lost motion in the rod connections

and in the boxes. The effect of this lost motion is to delay the

movement of the valves; and, unless they are set with a lead opening,

the stroke of the piston would in some instances be commenced

before steam got into the cylinder. It is also found in practice,

that this lost motion would cause a pounding at each change in

the direction of the piston's travel, unless there is the necessary

cushion to bring the cranks smoothly over the centers. Without

cushion, the change of direction of the piston's travel is effected

by a series of jerks that are hard on the working-parts. So long

as the lead opening at the beginning of the stroke is not advanced

enough to produce injurious counter pressure upon the piston,

it improves the working of the engine by causing a prompt opening

for steam admission at the beginning of the stroke. This is the

time that a full steam-pressure is wanted in the cylinder, if

economical working be a consideration. A judiciously arranged

lead opening is therefore an advantage; since it increases the

port opening at the proper time for admitting steam, tending to

give nearly boiler pressure in the cylinder at the beginning of

the stroke. With the shifting link-motion, the amount of lead

opening increases as the links are hooked back towards the center

notch; the magnitude of the increase, in most cases, being in

direct proportion to the shortness of the eccentric-rods. A common

lead opening in full gear with the shifting link is z

inch, which often increases to a

inch in the center notch. The tendency of wear and lost motion

is to neutralize the lead, so that, when a locomotive motion gets

worn, increasing the lead will generally improve the working of

the engine.

OPERATION OF THE STEAM IN THE CYLINDERS.

As the work performed by a steam-engine is in direct

proportion to the pressure exerted by the steam on the side of

the piston which is pulling or pushing on the crank-pin, it is

important that the steam should press only on one side of the

piston at once. Hence, good engines have the valves operated so

that, by the time a stroke is completed, the steam, which was

pushing the piston, shall escape, and not obstruct the piston

during the return stroke, and so neutralize the steam pressing

upon the other side. When an engine is working properly, the steam

is admitted alternately to each side of the piston; and its work

is done against a pressure on the other side not much higher than

that of the atmosphere.

BACK PRESSURE IN THE CYLINDERS.

When, from any cause, the steam is not permitted to

escape promptly and freely from the cylinder at the end of the

piston stroke, a pressure higher than that of the atmosphere remains

in the cylinder, obstructing the piston during the return stroke,

and causing what is known as back pressure. There is seldom trouble

for want of sufficient opening to admit steam to the cylinders,

for the pressure is so great that the steam rushes in through

a very limited space; but, when the steam has expanded two or

three times, its pressure is comparatively weak, and needs a wide

opening to get out in the short time allowed. This is one reason

why the exhaust-port is made larger than the admission-ports.

Nearly all engines with short ports suffer more or less from back

pressure, but the most fruitful cause of loss of power through

this source is the use of extremely contracted exhaust nozzles.

Were it not for the necessity of making a strong artificial draught

in the smokestack, so that an intense heat shall be created in

the fire-box, quite a saving of power, now lost by back pressure,

would be effected by having the exhaust opening as large as the

exhaust-pipe. This not being practicable with locomotives, engineers

should endeavor to have their nozzles as large as possible consistent

with steam-making.

Engines with very limited eccentric throw will often cause

back pressure when hooked up, through the valve not opening the

port wide enough for free exhaust.

Locomotives suffering from excessive back pressure are nearly

always logy. The engine can not be urged into more than moderate

speed under any circumstances; and all work is done at the expense

of lavish waste of fuel, for a serious percentage of the steam-pressure

on the right side of the piston is lost by pressure on the wrong

side. It is like the useless labor a man has to do turning a grindstone

with one crank, while a boy is holding back on the other side.

The weight of obstruction done by the boy must be subtracted from

the power exerted by the man to find the net useful energy exerted

in turning the grindstone. In the same way, every pound of back

pressure on a piston takes away a pound of useful work done by

the steam on the other side.

EFFECT OF TOO MUCH INSIDE LAP.

Engines that have much inside lap to the valves are

likely to suffer from back pressure when high speed is attempted.

The inside lap delays the release of the steam; and, where the

piston's velocity is high, the steam does not escape from the

cylinder in time to prevent back pressure.

RUNNING INTO A HILL.

Most of engineers are familiar with the tendency of

some engines to "run into a hill." That is, so soon

as a hill is struck, they suddenly slow down till a certain speed

is reached, when they will keep going. This is generally produced

by back pressure, its obstructing effect being reduced when the

engine is moving slow.

COMPRESSION.

The necessity which requires lap to be put on a slide-valve

to produce an early cut-off, in its turn causes compression, by

the valve passing over the steam-port, and closing it entirely

for a limited period towards the end of the return stroke. As

the cylinder contains some steam which did not pass out while

the exhaust-port was open, this is now squeezed into a diminishing

space by the advancing piston. In cases where too much steam was

left in the cylinders through contracted nozzles or other causes,

or where, through mistaken designing of the valve-motion, the

port is closed during a protracted period, the steam in the cylinder

gets compressed above boiler tension, and loss of useful effect

is the result. Under proper limits, the closing of the port before

the end of the stroke, and the consequent compression of the steam

remaining in the cylinder, have a useful effect on the working

of the engine by providing an elastic cushion, which absorbs the

momentum of the piston and its connections, leading the crank

smoothly over the center. Where it can be so arranged, the amount

of compression desirable for any engine is the degree that, along

with the lead, will raise the pressure of the cylinder up to that

of the boiler at the beginning of the stroke. When this can be

regulated, the compression performs desirable service by cushioning

the working-parts, thereby preventing pounding, and by filling

up the clearance space and steam passages, by that means saving

live steam. Compression probably does some economical service

by reheating the cylinder, which has a tendency to get cooled

down during the period of release, and by re-evaporating the water,

which forms by condensation of steam in the cool cylinder.

Engines that are running fast require more cushioning than

those that run slow, or at moderate speeds. The link-motion, by

its peculiarity of hastening compression when the links are hooked

up, tends to make compression a useful service in fast running.

DEFINITION OF AN ECCENTRIC.

The reciprocating motion which causes the valves to

open and close the steam-ports at the proper periods, is, with

most locomotives, imparted from eccentrics fastened upon the driving-axle.

An eccentric is a circular plate, or disk, which is secured to

the axle in such a position that it will turn round on an axis

which is not in the center of the disk. The distance from the

center of the disk to the point round which it revolves is called

its eccentricity, and is half the throw of the eccentric. Thus,

if the throw of an eccentric requires to be 5 inches, the distance

between the center of the driving-axle and the center of the eccentric

will be 22, inches. The movement

of an eccentric is the same as that of a crank of the same stroke,

and the eccentric is preferred merely because it is more convenient

for the purposes to which it is applied than a crank would be.

EARLY APPLICATION OF THE ECCENTRIC.

On the early forms of locomotives, a single eccentric

was used to operate the valve for forward and back motion. The

eccentric was made with a half circular slot, on which it could

be turned to the position needed for forward or back motion. It

was held in the required position by a stop-stud fastened on the

axle. Several forms of movable eccentrics were invented, and received

considerable application during the first decade of railroad operating;

but the best of them provided an extremely defective reversing

motion. The first engineer to apply two fixed eccentrics as a

reversible gear was William T. James of New York, who made a steam

carriage in 1829, and worked the engine with four eccentrics,—two

for each side. The eccentrics were connected with a link, but

the merits of that form of connection were not then recognized

here; for it was not applied to locomotives till it became popular

in England, and was re-introduced to this country by Rogers. The

advantage of the double fixed eccentrics seemed, however, to be

recognized from the time James used them; for the plan was adopted

by our first locomotive builders. The first locomotive built by

Long, who started in 1833 what was afterwards known as the Norris

Locomotive Works, Philadelphia, had four fixed eccentrics.

RELATIVE MOTION OF PISTON AND CRANK,

SLIDE-VALVE, AND ECCENTRICS.

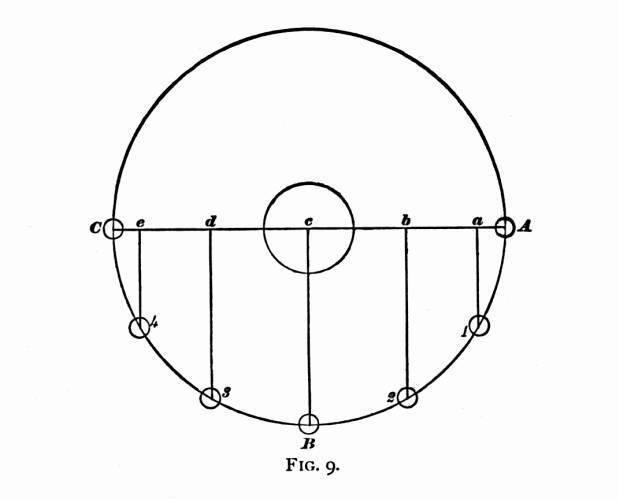

When a locomotive is running, the wheels turn with

something near a uniform speed; but any part which receives a

reciprocating motion from a crank or eccentric travels at an irregular

velocity. Fig. 9 shows the relative motion of the crank-pin and

piston during a half revolution. The points in the path of the

crank-pin marked A, 1, 2, B, 3, 4, C, are

at equal distances apart. The vertical lines run from them to

the points a, b, c, d, e, represent the position of the

piston in relation to the position of the crank-pin. That is,

while the crank-pin traverses the half-circle, A B C, to

make a half revolution, the piston, guided by the

cross-head, travels a distance within the cylinder equal to

the straight line A C. The crank-pin travels at nearly

uniform speed during the whole of its revolution, but the piston

travels with an irregular motion. Thus, while the crank-pin travels

from A to 1, the piston travels a distance equal to the

space between A and a. By the space between the

lines, it will be seen that the piston travels slowly at the beginning

of the stroke, gets faster as it moves along, reaches its highest

velocity about half stroke, then slows down towards the end till

it stops, and is ready for the return stroke.

ATTEMPTS TO ABOLISH THE CRANK.

Certain mechanics and inventors have been terribly

harassed over this irregular motion of the piston, and numerous

devices have been produced for the purpose of securing a uniform

motion to the power transmitted. These inventions have usually

taken the shape of rotary engines. Probably the fault these people

find with the reciprocating engine is one of its greatest merits,

for the piston stopping at the end of each stroke permits an element

of time for the steam to get in and out of the cylinder.

VALVE MOVEMENT.

The valve travels in a manner similar to the piston;

although its stroke is much shorter, and its slow movement is

towards the limit of travel. The small circle in the figure shows

the orbit of the eccentric's center, and the valve-travel is equal

to the rectilinear line across the circle. If the valve opened

the steam-ports at the outside of its travel, the slow movement

at that point would be an objection, since the operation of opening

would be slow: but the valve opens the ports towards the middle

of its travel, when its velocity is greatest; and, the nearer

to the mid travel the act of opening is done, the more promptly

it will be performed. This has a good deal to do with making an

engine "smart" in getting away from a station.

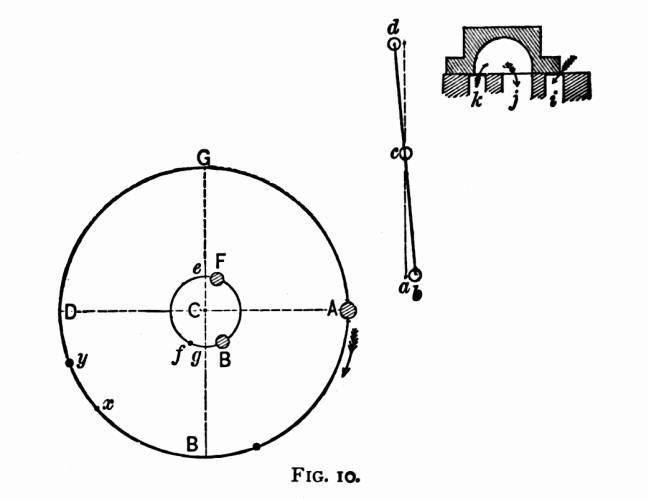

EFFECT OF LAP ON THE ECCENTRIC'S POSITION.

With the short valve without lap used on the earliest

forms of locomotives, the eccentric was set at right angles to

the crank or "square" on the dotted line e, Fig.

10. The least movement of the eccentric from its middle position

had the effect of opening the steam-ports. One advantage about

an eccentric set in this position, was that it opened and closed

the ports when moving the valve at its greatest velocity. Lengthening

the valve-face by providing lap entails a change in the location

of the eccentric; for, were it left in the right-angle position,

the steam-port would remain covered till the eccentric had moved

the valve a distance equal to the extent of the lap on one end,

and the piston would begin its stroke without steam.

ANGULAR ADVANCE OF ECCENTRICS.

The change made on the eccentric location is to advance

it from e to F, being a horizontal distance equal

to the extent of lap and lead, and known as the angular advance

of the eccentric. The centers F and B represent

the full part, or "belly," of the forward and back eccentrics

in the position they should occupy, where a rocker is employed,

when the piston is at the beginning of the backward stroke. It

will be perceived that the eccentrics both incline towards the

crank-pin, and the eccentric which is controlling the valve follows

the crank-pin. Thus, when the engine is running forward, F

follows the crank: when she is backing, B follows.

It is a good plan for an engineer to make himself familiar

with the proper position of the eccentrics in relation to the

crank, for the knowledge is likely to save time and trouble when

any thing goes wrong with the valve-motion. With this knowledge

properly digested, a minute's inspection is always sufficient

to decide whether or not any thing is wrong with the eccentrics.

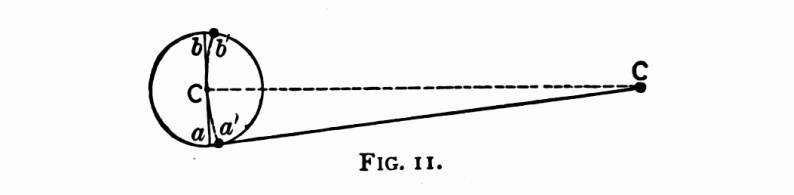

ANGULARITY OF CONNECTING ROD.

In following out the relative motion of the piston

and crank, we discover a disturbing factor in what is called the

angularity of the connecting rod, which has a curiously distorting

effect on the harmony of the motion. When the piston stands exactly

in the mid-travel point, the true length of the main rod will

be measured from the center of the wrist-pin to the center of

the driving-axle. If a tram of this length be extended between

these points, this will be found correct, as every machinist accustomed

to working on rods knows. Now, if the back end of the tram should

be raised or lowered towards the points where the center of the

crank-pin must be when the crank stands on the top or bottom quarter,

it will be found that the tram point will not reach the crank-pin

center, but will fall short a distance in proportion to the length

of the main rod. The dotted lines a' and b' in Fig.

11 show how far a rod 72 times

the length of the crank falls short. A shorter rod will magnify

this obliquity, while a longer rod will reduce it.

EFFECT ON THE VALVE-MOTION OF CONNECTING-ROD

ANGULARITY.

As the opening and closing of the steam-ports by the

valves are regulated by the eccentrics, which are subject to the

same motion as the crank, following it at an unvarying distance,

it is evident that their tendency will be to admit and cut off

steam at a certain position of the crank's movement. If the motion

is planned to cut off at half stroke, it will be apparent, that,

in the backward stroke, the piston will be past its mid travel

before the crank-pin reaches the quarter, so that end of the cylinder

will receive steam during more than half the stroke. On the forward

stroke of the piston, however, the crank-pin will reach the quarter

before the piston has attained half travel; the consequence being,

that in this case steam is cut off too early. The disturbing effect

of the angularity of the connecting rod on the steam distribution

thus tends to make the cut-off later in the backward stroke than

in the forward stroke, resulting in giving the forward end of

the cylinder more steam than what is admitted in the back end.

The link-motion provides a convenient means of correcting the

inequality of valve opening due to the connecting-rod angularity,

the details of which will be explained farther on.

AIDS TO THE STUDY OF VALVE-MOTION.

An engineer or machinist who wishes to study out this

peculiarity of connecting-rod angularity, will find that the use

of a tram or long dividers will help him to comprehend it better

than any letter-type description. All through the study of the

valve-motion, there are numerous difficult problems encountered.

The use of a good model will be found an invaluable aid to the

study of the valve-motion, and every division of engineers or

firemen should make a combined effort to furnish their meeting-room

with a model of a locomotive valve-motion. In no way can the spare

time of the men connected with locomotive running be better employed

than in the wide range for study presented by a well devised model.

Great aid can be obtained in the study of the valve-motion from

good books devoted to the subject, and they will impart more information

than can be obtained by mere contact with the locomotive. The

valve and its movements are surrounded with so many complicated

influences, that an intelligent man may work for years about a

locomotive doing valve setting occasionally, and other gang boss

work, yet, unless he studies the valve-motion by the aid of the

drawing board, or by models, which admit of changing sizes and

dimensions, he may know less about the cause of certain movements

than the bright lad who has been a couple of years in the drawing-office.

The man who thinks he can study the valve-motion, and understand

its philosophy, by merely running the engine, deceives himself.

The engineer who never looks at a book or a paper in search of

information about his engine, knows very little about any thing

not visible to the eye. Yet many men of this stamp, by looking

wise, and by exercising a judicious use of silence, pass among

their fellows as remarkably profound. But let a fireman, in quest

of locomotive knowledge, put a question to such a man, and he

is immediately silenced with a "You ought to know better"

answer.

Where the use of a model can not be obtained, any one beginning

the study of the valve-motion can assist himself by making a cross

section of the valve and its seat, similar to those published,

on a strip of thin wood or thick paper. By slipping the valve

on the seat, its position at different parts of the stroke can

be comprehended more clearly than by a mere description. With

a pair of dividers to represent the motion of the eccentric, and

strips of wood to act as eccentric, and valve rod and rocker,

and some tacks to fasten them together, a helpful model can be

improvised on a table or board. By the time a student gets a rig

of this kind going, he will see his way to contrive other methods

of self-help.

EVENTS OF THE PISTON STROKE.

By the aid of Fig. 10, we will trace the relative movements

of the crank and eccentric connections. For the sake of simplicity,

the eccentric is represented as connecting directly with the rocker-arm.

The crank-pin being at the point A, or the forward center,

the piston must be in the front of the cylinder, or at the beginning

of the backward stroke. Owing to the angular advance already referred

to, the eccentric center is at F; and, being a certain

distance ahead of the middle position, it has pushed the lower

arm of the rocker from a to b, drawing back the

top arm, which, in its turn, has moved the valve so that it is

just beginning to admit steam at the forward port, i. As

the crank-pin goes round, the eccentric follows it, opening the

steam-port wider till the eccentric reaches the point of its travel

nearest A, the limit of the throw. When the eccentric is

at this point of its throw, the valve must be at the outside of

its travel; and therefore the steam-port is wide open. By this

time the crank-pin is getting close up towards the quarter. After

passing this point, the forward eccentric begins to draw the bottom

rocker-pin towards the axle, and to push the valve ahead, this

being the point where the valve changes its direction of motion

just as the piston returns when the crank-pin passes the center.

When F reaches the point B, the valve is in the

same position it occupied at the beginning of the stroke; but,

as it is traveling in the opposite direction, a very small movement

more closes the port, cutting off steam. When this happens, the

crank-pin has reached the point x. When F gets to

g, it is on the central point of its throw; so the valve

must then be on the middle point of its travel, with the exhaust

cavity just covering the outside edges of the bridges, the forward

edge being ready to put the steam-port, i, in communication

with the exhaust cavity. This releases the steam from the forward

end of the cylinder; and at the same moment the inside edge of

the valve covers the back port, k, causing the piston-head

to compress any steam left in the back part of the cylinder. When

the piston reaches the beginning of the forward stroke, the eccentric

F has got to the point f, and the valve is beginning

to admit steam for the return stroke, the events of which are

similar to those described.

In actual practice, the steam distribution is a little different

from the manner that has been followed; for the link-motion provides

the means of equalizing the cutoff, making it uniform for both

strokes. This changes the events of the stroke a little; but the

student who engraves in his mind the movements as they are represented

in the diagram, will not be far astray.

WHAT HAPPENS INSIDE THE CYLINDERS WHEN

AN ENGINE IS REVERSED.

Many men who have a fair understanding of the action

of steam in an engine's cylinders during ordinary working, have

no idea of the operations performed in the cylinders when a locomotive

is running in reverse motion. All men who have had any thing to

do with train service, know, that, when an engine is reversed,

the action works to stop the train, even if the locomotive should

have no steam on the boiler; but just in what way this result

comes round they can not clearly perceive. In hopes of throwing

light upon this subject for those who have not studied it out,

we will follow the events of a stroke in reversed motion, as we

did in the ordinary working.

EVENTS OF THE STROKE IN REVERSED MOTION.

Supposing an engine to be running ahead, and the necessity

arises for stopping suddenly, and the reverse-lever is pulled

into the back notch. When the crank-pin is on the forward center,

and therefore the piston at the forward end of the cylinder, about

to begin its backward stroke, the valve has the forward port open

a distance equal to the amount of lead, as in Fig. 10. But, as

the back-up eccentric has control of the valve., the latter is

being pushed forward; and it closes the forward port just as the

piston begins to move back. This shuts off all communication with

the forward end of the cylinder; and the receding piston creates

a vacuum behind it, just as a pump-plunger does under similar

circumstances. At this time the back end of the cylinder is open

to the exhaust, and the piston pushes out the air freely to the

atmosphere. By the time the piston travels about two inches, the

valve gets to its middle position; and, immediately after passing

that point, it opens the forward end of the cylinder to the exhaust,

and closes the back port. When this event happens, the vacuum

in the forward end of the cylinder gets filled with hot gases,

that rush in from the smoke-box; and the receding piston keeps

drawing air into the cylinder in this way during the remainder

of the stroke, and air from that quarter seldom gets in without

bringing a sprinkling of cinders. The back steam-port is closed

only during about two inches of the stroke, while the lap of the

valve is traveling over it. About the time the piston reaches

four inches of its travel, the back steam-port is open to the

steam-chest, and the piston forces the air through the steam-pipes

into the boiler during the remainder of the stroke. The forward

stroke is merely a repetition of the backward stroke described.

When it is necessary to reverse a locomotive, it is a better

plan to hook the lever clear back than to have it a notch or two

past the center, as some men persist in doing, under the mistaken

belief that they are in some way saving their engine from harsh

usage. When the link is reversed full, the cylinders are merely

turned into air-pumps. When the links are put near the center,

the travel of the valve is reduced; and the periods when the piston

is creating a vacuum in one end of the cylinder, and compressing

the air in the other, are prolonged. The result is, that, when

the exhaust is opened in the first case, the gases rush in violently

from the smoke-box, carrying a heavy load of cinders: in the other

case, the piston compresses the air in the cylinder so high that

it jerks the valve away from its seat in trying to find outlet.

This causes the clattering noise in the steam-chest, so well known

in cases where engines are run without steam while the reverse-lever

is near the center.

A locomotive with the piston-packing in bad order will not

hold well running in reverse-motion. Some kinds of piston-packing

do not seem to act properly when the engine is reversed, especially

at low speed. Where a valve has much inside lap, there will be

a vacuum in one end of the cylinder, and compressed air in the

other end. With piston-packing that requires pressure to expand

it, the void at one end of the cylinder may neutralize the pressure

at the other by drawing the air through the piston. This would

be most liable to happen where the lever was kept near the center.

PURPOSE OF RELIEF-VALVE ON DRY PIPE.

Should the throttle-valve close so tight that the compressed

air from the cylinders can not pass into the boiler, there is

danger of bursting the steam-chest or some part of the, steam-pipes.

The compressed air will lift most of the throttle-valves far enough

to prevent any great danger from this source. In some engines

a relief-valve is secured in the dry pipe, which provides a passage

for this compressed air. When the cylinder-cocks of an engine

are opened when the motion is reversed, they form an outlet to

the compressed air, and also admit air to the sucking end without

letting the piston draw air so freely through the nozzles. Many

cylinder-cocks are now made so that they will open automatically

to permit the piston to draw air through them. The reversed engine

will stop nearly as well with the cylinder-cocks opened as when

they are closed, and it is much more easily handled with the cocks

opened. Where the cocks are kept closed, the rush of hot air from

the smoke-box laps every trace of oil from the valve-seat, and

a heavy pressure — frequently above that of the boiler —

is present in the steam-chest. When the engine stops under these

circumstances, its tendency is to fly back; and an engineer has

some difficulty in controlling it with the reverse-lever till

a few turns empty the chest and pipes.

USING REVERSE-MOTION AS A BRAKE.

Numerous attempts have been made to utilize the reversed

engine as a brake for stopping the train, and even by this means

to save some of the power lost in stopping. Chatelier, a French

engineer, experimented for many years on this mechanical problem.

He injected a jet of water into the exhaust-pipe, which supplied

low-tension steam to the cylinder, instead of hot gas or air coming

through the smoke-box. This was pumped back into the boiler on

the return stroke. Thus the act of stopping a train was used to

compress a quantity of steam, converting the work of stopping

into heat, which was forced into the boiler and retained to aid

in getting the train into speed again. Modifications of this idea

produce the car-starters that pass so frequently through our Patent

Office.

As a means of conserving mechanical energy, the Chatelier brake

was not a success; but, in the absence of better power brakes,

it met with some applications in Europe. Some of our mountain

railroads use it, under the name of the water-brake, as an auxiliary

to the automatic brake.

Table of Contents

| Contents Page

|